ULTRA-TRICK, 3-SPEED HONDA CR250 TWO-STROKE

Click on images to enlarge

It has been 13 years since a rider won an AMA National Championship on a 250cc two-stroke. That rider was Ricky Carmichael aboard his 2003 Factory Honda CR250, with its rolled-back bars, low-rider shock and cut-down seat. These days, the only place you’ll find a factory smoker is in a museum. Maybe no one will ever be able to throw a leg over Ricky Carmichael’s 2003 championship-winning bike again, but maybe the MXA wrecking crew could come close. How? The right connections. Chad Clemen is just an average Joe who dreamed of building the ultimate Honda CR250 two-stroke. He knew that if he built it, they would come.

No, we’re not talking about “Shoeless” Joe Jackson and the 1919 Chicago Black Sox coming out of a cornfield. Chad Clemen knew that if he built a unique-enough bike, the MXA gang would track him down like a bloodhound. So, once he found the bike he was looking for—a 2003 Honda CR250 on Craigslist—he started building.

“LET’S NOT GET TOO MISTY-EYED ABOUT THE 2003 HONDA CR250 ENGINE. IT WAS NOT A WINNER BY ANY STRETCH OF THE IMAGINATION.”

2003 HONDA CR250 ENGINE

Let’s not get misty-eyed about the 2003 Honda CR250 engine. It was not a winner by any stretch of the imagination. Here is exactly what MXA said about the 2003 CR250 when it was brand-spanking new: “The CR250’s powerband is its biggest handicap. It’s mellow, linear and smooth down low. It takes its good old time building revs, probably because of a confluence of multiple CDI maps, electric power-valve lag and overly generous crankcase volume. But, whatever the cause, the Honda CR250’s powerband is so smooth that most test riders couldn’t wait for it. They started keeping the revs up, feathering the clutch and rushing the CR around tight turns. By compensating for the CR250’s overly mellow powerband, CR riders only got access to half of the powerband. This split personality (mellow low end and potent upper middle) isn’t as usable as it could be, especially when compared to the immediate response and broad pull of the YZ250 and RM250, or even the more defined low end of the KX. Don’t cry for Honda; they knew that the CR250 powerband needed to hit harder, respond quicker and carry further. They made mods, but the mods weren’t rockers.”

So, Chad Clemen’s handpicked engine tuner had his work cut out for him. Chad wanted a full-tilt race engine that would blow away 450s on the way up Mount Saint Helens. The guy for the job was Terry Varner. Varner is an old-school tuner who specializes in two-strokes (and was on top of the game back in 2003). Terry is the Leonardo da Vinci of cylinder porting, as evidenced by the top-name riders he wrenched for over two decades.

Varner started on Chad Clemen’s engine by porting and decking the cylinder, modifying the head, and matching and machining the cases to move the reed block 1mm closer to the crankshaft to reduce crankcase volume. Crank Works rebuilt and balanced the crank, while a Wossner single-ring forged piston and connecting rod were installed to reduce weight. The stock 38mm Mikuni TMX carburetor has suffered jetting issues on the CR250 since it rolled off the showroom floor in 2003. Varner replaced it with a 38mm Keihin PWK carb (from a 2006 Suzuki RM250). Varner bored the carb to 39.5mm, hand-blended the intake and had the choke circuit removed.

Since an engine acts much like a vacuum, as it is fueled by the amount of air sucked in, Varner put a lot of work into increasing airflow. He did this by replacing the stock reed cage with a Boyesen RAD valve that was matched to a 2004 CR250 intake manifold. It made for a straighter and lower path to the reed block. A 2007 CR250 airboot was also installed, as it increased the air volume over the original.

THREE-SPEED TRANNY

In the midst of all this, Chad got an idea. He realized he never used first gear unless he was on a Sunday stroll through the pits, and only on occasion had he even touched fifth gear. So, he thought, why not make the tranny into a three-speed? Why on earth would he do that? Oh yeah, did we mention he wanted to make not only the fastest bike, but also the lightest CR250 ever built? Yeah, it was a bit crazy, but that makes Chad fit in with the rest of us. Chad put Terry Varner’s engine work on hold and sent the CR250’s stock five-speed transmission to RCR Race Transmissions to have them make it into a three-speed. On top of throwing two gears out the window, RCR did everything under the sun to make the tranny shift smoothly between gears and to lighten all the parts.

There was one potential wrench in Chad’s transmission plan. With the three-speed configuration, neutral ended up where first gear was. That’s right; if you downshifted where first used to be, you’d end up going over the bars. Chad knew the risks versus rewards but wanted to try it anyway. The MXA wrecking crew has some experience with neutral-on-the-bottom transmissions, as they were used on Italian boutique Vertemati and VOR motorcycles in the 1990s. Back then we developed the “Dirty Harry” shift system, where we counted shifts while racing. When we downshifted, we would say to ourselves, “I know what you’re thinking. Did I downshift one time or two? You’ve got to ask yourself one question: do you feel lucky? Well, do ya, punk?”

SHOWA TO KAYABA SUSPENSION

The stock 2003 Showa components were tossed out and replaced with Kayaba A-kit components. The forks were based off the 2012 CRF450 AOSS forks and the 2015 CRF450 shock. The talented Graeme Brough was the brains behind the setup. Graeme, who was a suspension technician for Factory Honda, used his experience and contacts to build the best suspension package money could buy. An RCS titanium shock spring was mounted to the A-kit shock shaft, along with a boatload of works internals. To add to the list, the fork tubes, cartridges and shock body were Kashima-coated, and the fork lugs were anodized gray.

THE LOVING TOUCHES

When Terry got the three-speed tranny back, he put the finishing touches on the bike while Chad dreamed about how to make the project complete. On Varner’s end, he utilized a Zeeltronic CDI that allowed him to custom-tune the mapping for the ignition, power valve and power jet. Developing the Zeeltronic software was no easy task. The monitor looks like a scene from the Matrix. Varner burned the midnight oil countless nights on the dyno to find the perfect curve that would iron out the dips and valleys. He also beefed up the clutch to a Rekluse Torq-Drive manual clutch to withstand the beating of the added ponies.

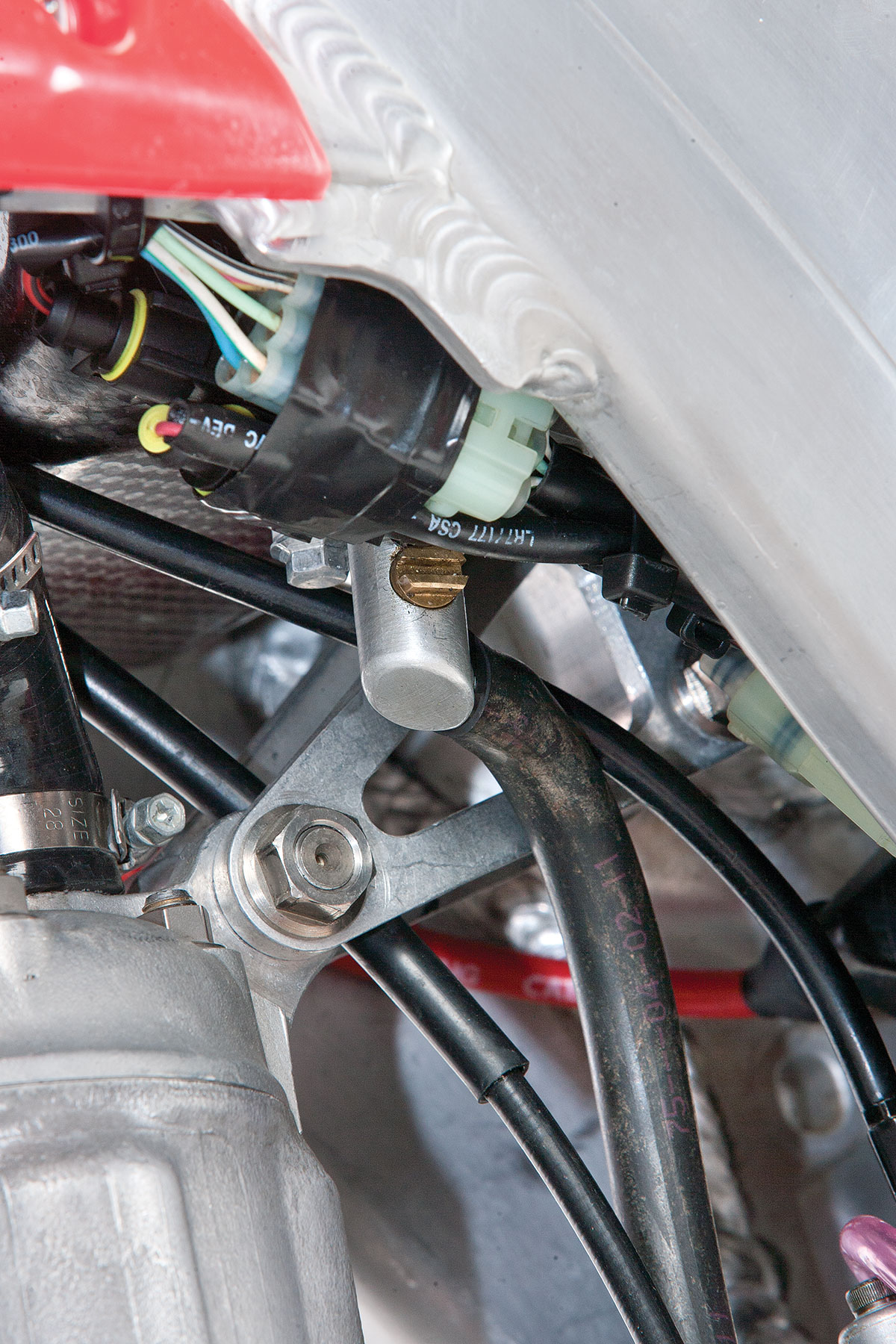

A works billet-aluminum petcock that’s turned on and off by a flathead screwdriver was mounted for safety as well as weight savings.

On Chad’s end, he showed up with boxes of titanium and carbon fiber parts. RaceTech titanium hardware replaced many of the regular bolts; however, the big weight savings was in the Ti axles, linkage and pivot fasteners. Chad went on a shopping spree in the Lightspeed warehouse. He got titanium footpegs, which were lowered 8mm, and a carbon fiber ignition cover, pipe hanger, chain guide and glide plate. But, probably one of the trickest parts on the bike was the carbon fiber CMT fuel tank. It holds a quarter of a gallon more fuel and has a sunk-in, billet-aluminum gas cap. The CMT tank is mounted to a works billet-aluminum petcock that is turned on and off by a flathead screwdriver (his lips were sealed about his source).

BIG BRAKES

To increase stopping power, both the front and rear brake systems were replaced with new-school technology. Chad traded the front caliper for a Ride Engineering unit with custom-machined pistons that were mated to a 2012 CRF450 master cylinder and added a Moto Stuff 260mm oversized front rotor. As for the rear, the OEM rear caliper was modified to reduce weight and allow better cooling. The caliper was DLC-coated, and the piston was fluted to reduce heat build-up and drag. A 2015 CRF450 rear rotor was modified then mounted to reduce weight.

The transformed 2003 Honda CR250 was built to the hilt. The list of mods and upgraded parts goes on and on like a kid’s wish list on Christmas. Chad thought of every conceivable part and modification that could make this bike as close to factory as possible. The list of mods and upgraded parts goes on and on like Santa’s list on Christmas. Chad thought of every conceivable part and modification that could make this bike as close to factory as possible. With shaving over ten pounds, this brings the weight well under the AMA weight limit. Not too bad for just an average Joe, but how was it on the track.

Each rider who got on Chad’s CR250 two-stroke was skeptical about the neutral-on-the-bottom tranny, and the old-school test riders didn’t make matters any better by telling horror stories of racing the Italian boutique bikes. The faster the rider, the less trouble he had with accidentally finding neutral, but the Vet test riders weren’t as good at counting and riding at the same time. All in all, neutral was not a big issue once the riders became familiar with the gearbox. What was a problem was how tall second gear was in the pits. There is a difference between blasting off the starting line in second gear and trying to leave the pits at an acceptable rpm. Most test riders stalled the bike the first time out, as second gear is tall from a standstill. We went up one tooth in the rear, which made things easier in the pits and actually helped on the track too. This was a happy medium for everyone. As for fifth gear being gone, no one even noticed.

We also had issues when we crashed. When we picked up the bike after a tip-over, the engine would flood. The easiest way to start a flooded bike is to shut the gas petcock off, kick the bike over to pump the excess fuel out of the low end, and turn the petcock back on when the bike fires up. Well, without a flat-blade screwdriver to turn the gas on or off, it was a waiting game to turn over the engine.

Remember what we said about the stock 2003 Honda engine? It was, “Mellow, linear and smooth down low. It takes its good old time about building revs, probably because of a confluence of multiple CDI maps, electric power-valve lag and overly generous crankcase volume. But, whatever the cause, the Honda CR250 powerband is so smooth that most test riders couldn’t wait for it.” Well, Terry Varner’s updated porting, carb update, electronics and reed mods produced a power curve that was a lot like that of the 2016 KTM 450SXF four-stroke. Say what? That isn’t a slam; it just means the test riders didn’t realize how fast they were going due to the CR250’s smooth, linear curve throughout the entire powerband. The engine gets the power to the ground more like a four-stroke instead of breaking loose like a two-stroke. When it comes to power versus weight, this CR250 was blowing by 450s up Mt. Saint Helens, just as long as the rider kept the front wheel on the ground.

The Graeme Brough suspension was set for a 200-pound Novice rider. Amazingly, this was deemed perfect by our faster and lighter Pro test riders. There were no complaints. Big bumps, small bombs or hard hits—it didn’t matter. The Graeme Brough-tuned suspension was like riding a hovercraft.

One of the best features of the bike was its agile handling. It felt like a 125 chassis with 250 power. Our testers could put the bike where they wanted to, when they wanted to. Overall, Chad Clemen’s CR250 build is the result of a big dreamer getting his every wish on every detail of the bike. Every rider loved to ride it—although none of our test riders could afford to build it. This bike is as close to factory as you can get to Carmichael’s AMA Championship-winning Honda CR250, except that Ricky’s engine had no bottom, hit like a stick of dynamite in the middle and cracked windows at high rpm. How do we know? We rode it.

Comments are closed.