TEN THINGS YOU NEED TO KNOW ABOUT DUAL-FUEL INJECTION

(1) Powerband. The problem for the fuel-injection system of a motocross engine is that it has to work over a very wide rpm range. A fuel injector that can deliver a perfect mixture at 5000 rpm is overworked to do the same thing at 13,000 rpm. All modern fuel-injected motocross bikes have a single-injector nozzle located the same distance away from the combustion chamber as an old-school carb. All of them, save for the dual-injector KX250F—which has the standard injector and a second one upstream in the air boot. When first released, Kawasaki’s dual-fuel concept was a revelation. It was expected that every manufacturer would adopt the idea of dual injectors…but they didn’t. Kawasaki has stuck with the idea and has produced very strong and broad powerbands every since it was introduced in 2012.

(1) Powerband. The problem for the fuel-injection system of a motocross engine is that it has to work over a very wide rpm range. A fuel injector that can deliver a perfect mixture at 5000 rpm is overworked to do the same thing at 13,000 rpm. All modern fuel-injected motocross bikes have a single-injector nozzle located the same distance away from the combustion chamber as an old-school carb. All of them, save for the dual-injector KX250F—which has the standard injector and a second one upstream in the air boot. When first released, Kawasaki’s dual-fuel concept was a revelation. It was expected that every manufacturer would adopt the idea of dual injectors…but they didn’t. Kawasaki has stuck with the idea and has produced very strong and broad powerbands every since it was introduced in 2012.

(2) Intake pressure. With a carburetor, the fuel must enter the intake tract and rely on intake pressure to draw fuel out of the float bowl and blend it with the incoming air. Electronic fuel injection doesn’t rely on intake pressure; instead, it has a fuel pump that sprays fuel into the intake tract in metered doses. And, Kawasaki’s dual-injector system has a primary and a secondary injector that both work together to deliver the optimum amount of fuel based on rpm, throttle opening and other sensor data.

(3) Precursors. Dual fuel injectors have, however, been utilized on street bikes for years. Honda first used the concept with their 2003 CBR600RR. That bike had a second set of “showerhead” injectors installed in the roof of the airbox.

(4) Breathing. On each intake cycle an engine draws a breath of air from the intake tract, which can be viewed as a long column of air. At low rpm, the engine is taking quick, little breaths and only using a fraction of that long column of air. A single fuel-injector nozzle must be placed next to the intake port to deliver fuel at low rpm. At high rpm, however, when the engine is drawing in the whole long column of air, a secondary injector can take advantage of the long column of air. Atomization is what counts, and dual injectors can keep up with the needs of low and high rpm running.

(5) Turbulence. Spaying fuel with an injector nozzle as far upstream of the intake port as possible gives the fuel time to atomize while being tumbled in the natural turbulence of the intake tract. At 11,000 rpm, the engine is gulping huge columns of air, and injecting the fuel upstream gives the gas a much better chance to create an even fuel/air mixture. It is also claimed that the upstream injector cools down the intake charge to make the mixture denser with oxygen, which translates into more power.

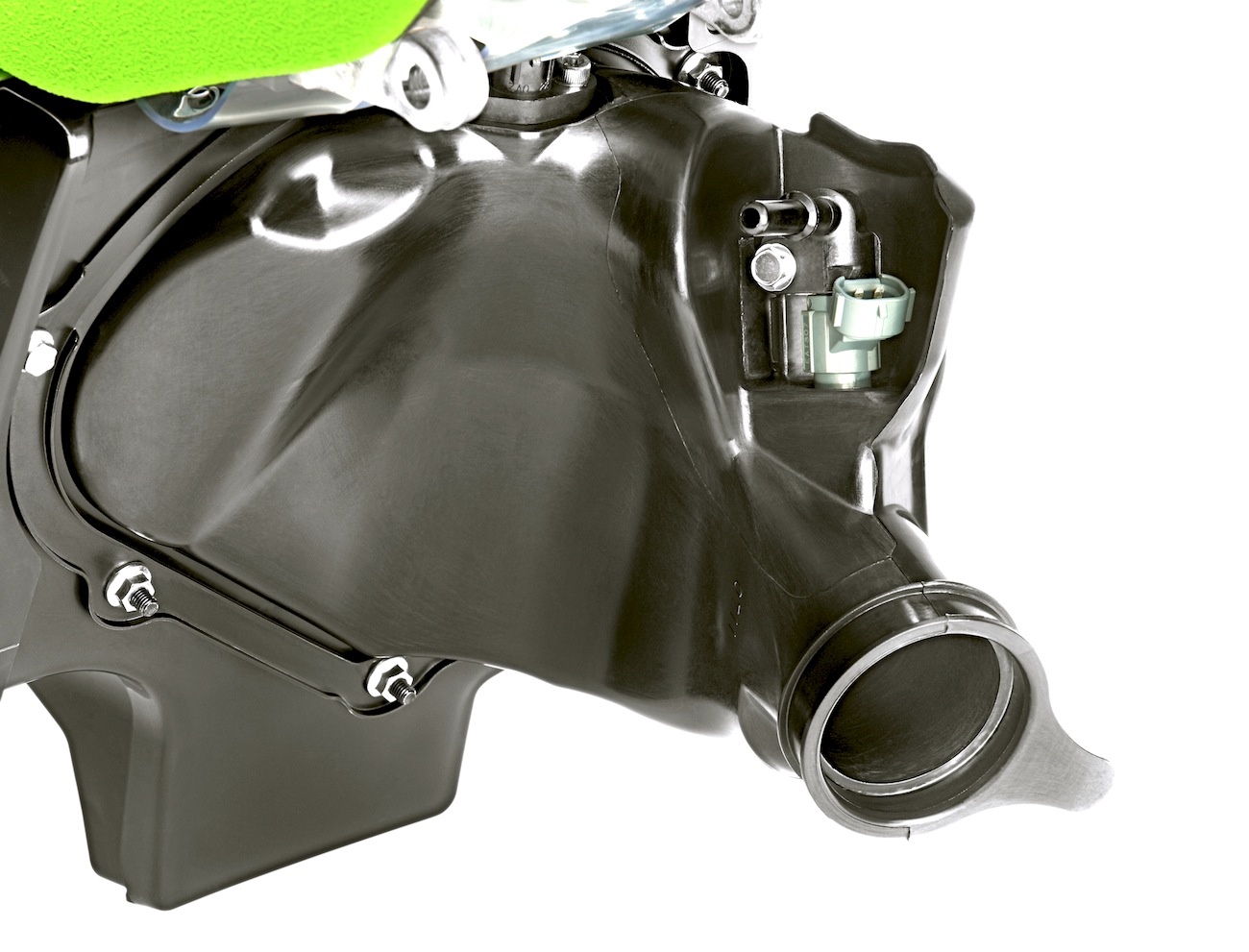

(6) KX250F injectors. Starting in 2012, Kawasaki equipped their KX250F with two injectors. The Kawi’s second injector is located inside the air boot. Both Kawasaki injectors have the same output capacity. In the KX250F system, only the first injector is running until 7000 rpm. At 7000 rpm, the upstream injector kicks in and gradually increases fuel delivery while the first injector gradually tapers off. When the bike is running wide open, only the upstream injector is working. This is contrary to Kawasaki’s ZX sport bikes, whose downstream injectors stay on at high rpm. All numbers and theories aside, a seat-of-the-pants evaluation of the 2012-13 KX250F versus the 2011 single injector is plain as day — the dual-injected bike romps it.

(7) Timing. Dual injectors make CPU programming more critical. The two injectors must blend together seamlessly to optimize fuel delivery. When several race teams tried using a secondary injector simultaneously with a downstream injector, it didn’t work. The secondary injector needs to come into the action when the engine rpm is high enough to utilize it. The extra time it takes for the upstream injector’s fuel to reach the combustion chamber must be taken into consideration.

(8) Fuel pressure. The EFI on current motocross bikes is a constant pressure system that doesn’t vary fuel pressure. There is such a thing as “continuous injection,” where pressure rates vary, but that’s beyond the scope of current motocross CPUs. The amount of fuel delivered by current motocross EFI systems depends on how long the injector is turned on, which is called “pulse width.” Obviously, two injectors add more dimension to the pulse-width equation.

(9) Turbo lag. There is a certain amount of lag time from when the CPU sends the signal to turn the injector on and when it actually turns on. This lag can be a millisecond or more. When the pulse width is only 2 milliseconds, a delay of a millisecond is substantial.

(10) Mutually dependent. On a single-injector engine, the engineers must figure out an average lag time and increase the pulse width accordingly to cover all the bases. With two simultaneously operating injectors, the pickup delay can easily be covered up by the difference between fuel traveling a short distance and fuel coming from farther away. One thing is certain: dual injectors are here to stay, because they work on an engine that makes power from 5000 rpm to 13,000 rpm.

Comments are closed.