EKS BRAND’S RICH TAYLOR ON THE FAMILY BUSINESS

EKS Brand is a full-on family operation. Rich Taylor (middle) has his wife Melissa, his father Hook (far left), his sons Richard and Zach, and his friend Jason Lighthart working alongside him.

EKS Brand is a full-on family operation. Rich Taylor (middle) has his wife Melissa, his father Hook (far left), his sons Richard and Zach, and his friend Jason Lighthart working alongside him.

Like many young riders, Rich Taylor was determined to make a career out of racing motorcycles from an early age. Most dreams like his never come to fruition; however, with hard work and the help of his family and friends, Rich has continued to earn a living in the motorcycle industry. It started with motorcycle racing and testing, which eventually led to the creation of EKS Brand goggles. EKS Brand is built on the family’s multi-generational experience in the goggle business, and, since 2009, EKS Brand has been known for offering quality goggles at an affordable price. Now, with the introduction of the all-new Lucid goggle coming at the same time that our industry has seen record numbers in sales, EKS Brand has been selling out every shipment it gets. We decided to check in with Rich Taylor to get the full backstory on how the EKS Brand began and how it’s operating today.

WHEN DID EKS BRAND GOGGLES COME TO LIFE? I originally started the company under the name “XBrand” in 2009. I was working full-time for Suzuki, doing the race team and production bike R&D testing. My friend Willy Musgrave worked at, and owned, part of a motorcycle accessory distributing company called MTA. Knowing my background and where I came from, he called me one day with an idea. He said that MTA had dropped Dragon goggles, and that if I came up with a new goggle brand, he would commit to ordering a full container’s worth of goggles. Basically, I just needed to design a goggle and order it, and they would buy every pair.

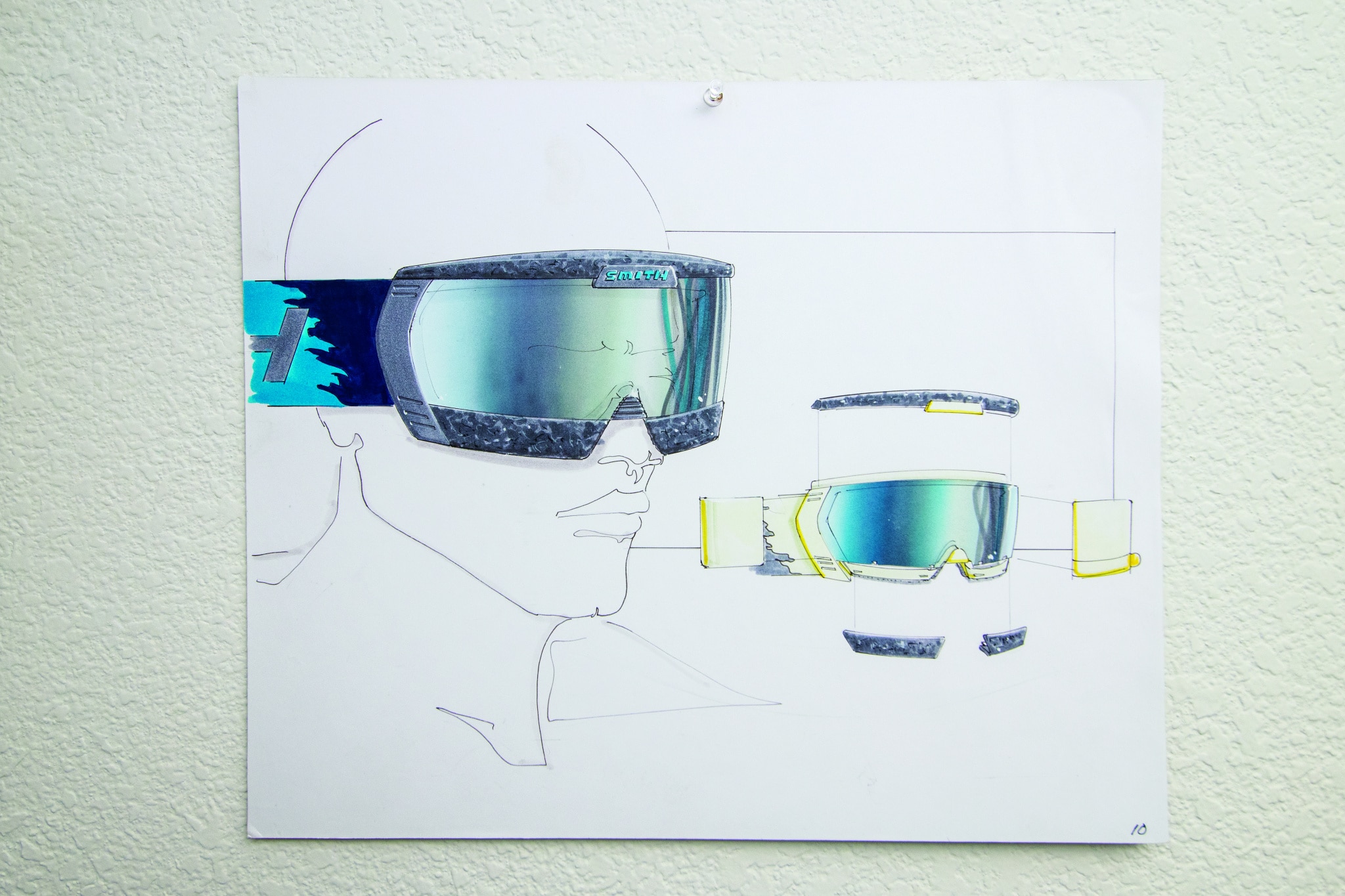

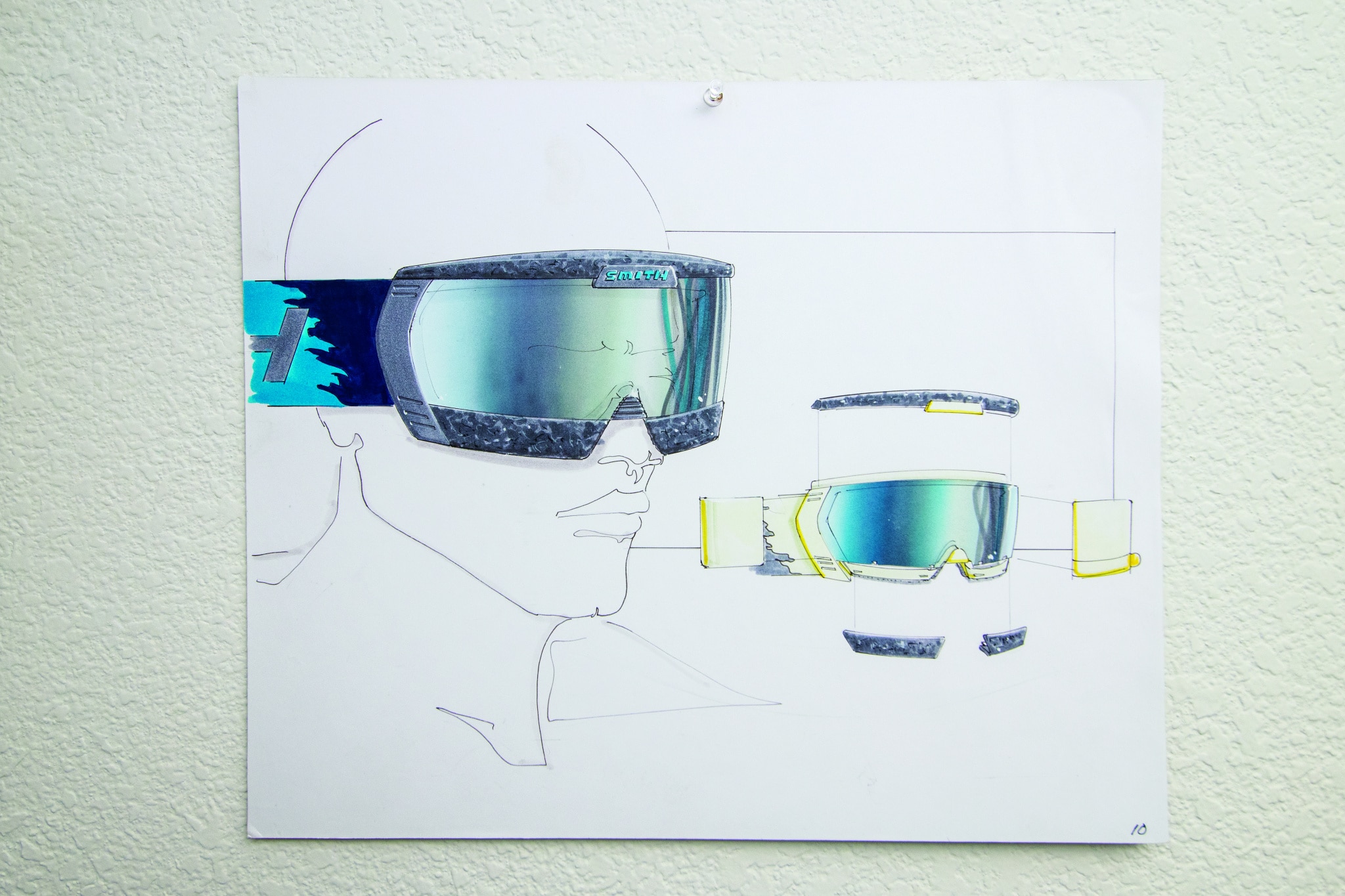

Rich Taylor’s father, Hook, came up with innovative goggle designs while working for Smith Goggles. Many of his ideas are still being used today.

Rich Taylor’s father, Hook, came up with innovative goggle designs while working for Smith Goggles. Many of his ideas are still being used today.

HOW DID YOU CREATE THE COMPANY FROM THERE? I immediately used my dad’s connections to figure out where the best goggles were built. It was pretty cool, because when I contacted this company about building our goggles, I talked to a guy named Jackim, and he knew who I was. He followed Supercross and was very knowledgeable about the racers. He also knew who my dad was. We quickly became friends, and he helped me out a bunch.

WHAT WERE YOUR NEXT STEPS? After locking down the factory, I designed a pretty basic goggle frame and incorporated some ideas that I always wanted in a race goggle. Obviously, racing and testing as long as I did, I had some really good ideas. Plus, I was still testing full-time with Suzuki, so I had some of the best racers in the country helping to give ideas and test these goggles for me every day. We started with about 22 variations of the original design—different shapes, durometers of urethane plastic material, different face foams, different dimensions, thicknesses, etc. We ended up with the original Gox goggle, which is still our best-selling model today.

The EKS Brand warehouse from above. Like many other businesses, EKS Brand has been selling out of product and having a difficult time to getting new shipments in.

The EKS Brand warehouse from above. Like many other businesses, EKS Brand has been selling out of product and having a difficult time to getting new shipments in.

HOW DID YOU COME UP WITH THE NAME “EKS BRAND”? Once we had the goggle finished and ready to build, I needed to start a company and have a name. I started doing stunts for TV and movies 14 years earlier in 1995. My first stunt job was actually doubling Jeremy McGrath on a Honda commercial. Some of my good friends had a stunt organization called “Brand X.” I always thought that was a really cool name, so I switched it around and called our company “X Brand.” Our first goggle strap was black and white with a big “X” on the side. I took a second loan out on my house to pay for 12,000 pairs of goggles and smiled all the way to the bank after I sold them all to MTA Distributing. Everything was going great until I got a cease and desist in the mail. This guy claimed he had the letter “X” trademarked for goggles and motorcycle eyewear. He wanted me to write him a check for $10,000.

HOW DID YOU GET AROUND THE CEASE AND DESIST? I didn’t know what to do, so I called Eddie Cole. Eddie was a super-fast racer in the 1970s, and he founded Answer Racing along with Six-Six-One, Matrix and many other very successful companies. Eddie is one of the most knowledgeable people in the motorcycle business. He was nice enough to sit down with me to strategize. I ended up working with one of his attorneys, and we found out that the guy who sent the cease and desist had nothing. His trademark had expired 23 years prior. Basically, I spent a bunch of money to find out it was all for nothing. That situation is why I recommend for young racers to stay in school, because it could have been avoided. After doing some more research, we found out that Oakley had the letter “X” trademarked for some clothing applications. I figured if Oakley had any kind of trademark of the letter “X,” I should probably change my name. I didn’t need to get into any kind of war with the biggest eyewear company in the world. We decided to spell out the letter “X” as EKS. We have our logo now trademarked along with the EKS logo; it all worked out.

“MY DAD, HOOK TAYLOR, WAS THE VICE PRESIDENT AT SMITH GOGGLES FOR ABOUT 15 YEARS. IT SEEMS LIKE EVERYONE KNOWS HOOK!”

The new EKS Brand Lucid goggles on display.

The new EKS Brand Lucid goggles on display.

WHAT IS YOUR FATHER’S HISTORY IN THE GOGGLE BUSINESS? My dad, Hook Taylor, was the vice president at Smith goggles for about 15 years. It seems like everyone knows Hook! He started as a ski rep in the Lake Tahoe area in the 1970s. Along with many ski, ski pole and ski boot companies, he also represented Scott goggles, Cebe goggles and Smith goggles over the years. In 1982, we moved to Sun Valley, Idaho, which was the home of Scott and Smith goggles at the time. Hook owned a ski shop and a car dealership in the Sun Valley area before heading up the motorsports division at Smith Sport Optics. My dad has ridden and raced motorcycles my whole life and was always into the motorcycle scene. A couple of his good friends are Bob Hannah and Danny Laporte.

HOW INVOLVED WAS YOUR FATHER IN DESIGNING GOGGLES? Hook is always looking for a better product or a better way to do something. He has been around ski and motorcycle goggles since he was 12 years old when he was a top ski racer at his local ski resort, Slide Mountain, just outside of Reno, Nevada. After his first few years at Smith, he had some amazing and very crazy goggle ideas for the time. Back then, you couldn’t just open illustrator on your computer and design something, so Hook hired a designer to come in and draw out some of his ideas. It’s amazing how ahead of their time some of these illustrations were. Easy lens-change concepts, wide roll offs, wide vision ideas, sweat channel ideas, face foam compounds, strap ideas, etc. These ideas were crazy for the day. Now, most of them are almost common.

Rich Taylor’s father, Hook, came up with innovative goggle designs while working for Smith. Many of the ideas are being used today.

Rich Taylor’s father, Hook, came up with innovative goggle designs while working for Smith. Many of the ideas are being used today.

WHICH GOGGLES DID YOUR FATHER HELP DESIGN? My dad came up with the Smith Violator goggle. Like the rest of his ideas, it was far ahead of its time. The lens slid in from the top of the goggle, the roll-offs mounted to the frame instead of the lens, and it had an amazing ventilation system that allowed you to change the foam blocks depending on how much air flow you needed. The Violator also had a rubber sweat gutter that allowed the sweat to run off your forehead onto the top of the goggle rather than soaking the foam. Unfortunately, it had a few problems. The Violator was supposed to be based off of the amazing face fit of the Scott 89 goggle. One of the designers at Scott had moved to Smith and said he had the CAD drawing of the Scott 89. Smith based the inner frame off of those CAD drawings. It turned out that the CAD he had was not the 89 goggles. After the designer left, Scott had totally changed it. The other issue was the size of the goggle. Because it had a very wide view, it was too big for the helmet eyeports of the time. Helmets were much smaller than today. The price was the final nail in the coffin. At $45, it was much too expensive for the time. But it sure was cool!

When he’s not out racing Supercross or the Nationals, Richard Taylor Jr. comes back to the shop to help run the family business.

When he’s not out racing Supercross or the Nationals, Richard Taylor Jr. comes back to the shop to help run the family business.

DID HOOK DESIGN THE SMITH WARP GOGGLE, TOO? Yes, that was another pretty cool goggle that he designed. The shape was completely different from any other goggle at the time, and it had a much bigger view. The face foam and strap were also advanced. The strap had rubber patches on both sides that actually stuck to the helmet so that the goggles wouldn’t move around. The problem was when your helmet moved, the goggles would move. So, if your helmet was a bit big or didn’t fit perfectly, it was not good. The face foam my dad used was also unique. It fit horribly until it got a little bit wet. Then it molded to your face and it would soak up all of the sweat. You would never drip sweat into your goggle during a moto. The problem was that it felt horrible until it got wet. Hook has so many amazing ideas. It was pretty cool doing our new Lucid project and doing our EKS-S goggle with him throwing out ideas. Some crazy, others that we used!

WHAT WAS YOUR RACING CAREER LIKE BEFORE STARTING EKS BRAND? Ever since I can remember, I’ve wanted to race motorcycles for a living. I have pictures of me at 3 years old on a big wheel wearing a helmet, gloves and goggles. I think once you watch your dad ride when you are a little kid, it’s all over. I started riding later than most, at 12 years old. I was a ski racer at a pretty high level as a kid, but I really wanted to race motocross. I finally started racing locally at 14. I was lucky enough to ride with Bob Hannah and Danny LaPorte. They would both spend most of their summers up in Sun Valley, Idaho. I was chasing them around on our gnarly mountain tracks. This helped me improve really fast. At 15, I won my first Pro race in Idaho. I quit ski racing in 1987, and I moved to Southern California to live with my mom and race. Danny Laporte introduced me to Karel Kramer, who was the editor of Dirt Rider magazine at the time. He asked if I wanted to do a test and photo shoot that next day. I did it, and I ended up on the cover of that issue. He continued to use me for the next 12 years before I started working at Transworld Motocross. It was pretty awesome back then, because magazines were all you had. I was making really good money, better than some top racers, because I was plastered all over the magazines every month.

HOW DID YOU GET INTO MOTORCYCLE TESTING? Willy Simons got me a testing deal with Honda. He was a super-fast, local, Southern California Pro, and I met him in 1987. In the beginning, I was doing just durability testing, which consists of doing three 30-minute motos a day, and each lap is timed. Usually, there are also six or seven top Pros out there doing laps with you, so it’s a full stopwatch race each day. You don’t want to be the slowest guy, and you do whatever it takes to have fast times. One time out at Glen Helen, while we were doing durability testing, Roger Decoster showed up. Luckily, I didn’t know he was there, and I was riding really well. I had the fast times that day. Had I known he was there I probably would have crashed. He talked to me for a while after my last moto, and he was really nice. He asked if I wanted to test a couple of parts on one of their race bikes. Basically, he wanted to test me to see if I could feel anything. I guess I faked it well, because they moved me into doing full R&D testing for the production and race team bikes at Honda. I am pretty sensitive to bike setup, which is really good for testing—and not so good for a full-time racer.

Rich Taylor (48) on the line with Tim Ferry (15), Jeremy McGrath (1), Jeff Emig (2), Phil Lawrence (13) and Damon Bradshaw (28).

Rich Taylor (48) on the line with Tim Ferry (15), Jeremy McGrath (1), Jeff Emig (2), Phil Lawrence (13) and Damon Bradshaw (28).

WERE YOU STILL RACING WHILE TESTING WITH HONDA? Yes, I was. I had a really good deal with Honda. They were paying me a salary to be a test rider, as well as giving me good bikes to race and also paying all my expenses. I raced the full Supercross and outdoor circuits for about 11 years. I had some pretty good finishes; I was as high as seventh overall in the 1993 National series. I was also able to race all over the world. Back then, you could make really good money doing Supercross races on nearly every continent. I feel bad for the racers today. I don’t think they have nearly the opportunities that I had to make money riding a motorcycle.

Rich and Richard, Jr.—Father and son.

Rich and Richard, Jr.—Father and son.

THEN YOU MOVED TO SUZUKI, RIGHT? Yes, when Roger and Jeremy McGrath moved over to Suzuki in 1997, I followed. Suzuki offered me a deal that was much less than what I made at Honda. Like a racer who didn’t go to college, I took the deal. I guess I figured it would get better. It took a couple of years, but my deal eventually got better, and I worked with Suzuki for almost 15 years.

NOW EKS BRAND HAS GROWN INTO A FULL-ON FAMILY BUSINESS. It’s an American dream. I feel very fortunate to be able to have my dad, wife and two boys working with me. It’s pretty funny, because there are people who think we are a massive company. I will get a customer that maybe got the wrong color goggle, or we forgot a pack of tear offs in his order or something, and he will send an email or call just ripping into us saying, “You screwed my order up. Who do I have to talk to for you to fix this?” Then I call them back and introduce myself and apologize. Then people freak out. I always get, “Wow, I wasn’t expecting you to call me.”

“I WAS ALSO ABLE TO RACE ALL OVER THE WORLD. BACK THEN, YOU COULD MAKE REALLY GOOD MONEY DOING SUPERCROSS RACES ON NEARLY EVERY CONTINENT.”

WHAT IS EACH PERSON’S ROLE IN THE FAMILY BUSINESS? Melissa, my wife, helps out with social media and sponsorship. Zach does pretty much everything from designing and testing to shipping. He runs the warehouse. Richard is still racing all of the Supercross races and Nationals, but when he is home, he mainly helps with testing new product and shipping. My dad’s job is to tell us all what to do! It’s nice having the family here every day. The fact that my boys Richard and Zach are learning how to do what we do is invaluable. I always try to make sure to have the boys around when I have to go to Western Power Sports, big shops or when I have to give a presentation. A few years ago, I had to get up and talk about our goggles in front of a room of 260 reps. I made the boys sit up on the stage with me to feel what it was like. Public speaking to me is way gnarlier than racing the Anaheim 1 Supercross! I think real-world situations like that are so important. Our entire company is getting a first-hand education in business 101. Besides the family, we have one other person on staff, Jason Lighthart. He has been with us basically since the beginning. Jason is amazing with graphics, websites and basically everything we need. Without him, I am not sure where we would be.

EKS BRAND HAS BEEN OUT OF STOCK A LOT LATELY, LIKE EVERYONE ELSE. HOW COME? We, like everyone else, have a huge issue with shipping. A container from overseas, today, costs about $18,000. At the beginning of the year, that same container cost $2400. And the shipping lead time today is about 90 to 120 days. Previously, the lead time was about 20 days. It makes it really hard to keep up with inventory.

The Taylor family garage is full of old helmets and gear along with Richard Jr.’s Suzuki RM-Z250.

The Taylor family garage is full of old helmets and gear along with Richard Jr.’s Suzuki RM-Z250.

THE NEW LUCID GOGGLE HAS BEEN IN THE WORKS FOR A LONG TIME. HOW DID THAT PROCESS GO? Wow, it was a nightmare. We had some amazing ideas to incorporate into a goggle for many years, but with CAD drawings, molds, prototypes, etc., it’s expensive to create a new goggle. To save some money when building the Lucid goggle, I started working with a new manufacturer. I worked with this company for over three years, and they could never get it right. We supplied the CAD drawings, we supplied the materials to use, and yet every sample we would receive was different and something would be wrong with it. Finally, after all that time I said, “I am done; we are out!” Three years went down the drain. I went back to my original factory and started from scratch right as the COVID pandemic hit. Luckily, my friend Jackim is now the president of that factory, and he helped to push the Lucid goggle through to get it finished as quickly as possible. It still took another two years before we had goggles.

WHAT MAKES THE LUCID GOGGLE BETTER THAN THE REST? With my dad’s history in the goggle industry, my racing background and the boys riding and racing every week, we incorporated a bunch of great ideas into the new Lucid. Our lens technology is amazing! Our XDO (Extreme Definition Optics) lens technology is made from the strongest impact-resistant polycarbonate material available and injection molded precisely for nearly zero visual distortion. And, our new Auburn After Burner tinted lens is amazing as well! It works in nearly all conditions, and it really highlights the definition in all types of terrain.

THE FRAME HAD TO BE STRENGTHENED TO WORK WITH THIS NEW LENS, RIGHT? To work with an injection-molded frame, we came up with a really cool “DYAD” sonic-welded hard outer frame that holds the lens in place and creates the ultimate defense against flying debris and heavy roost. This hard outer is bonded to an ultra-soft inner frame made of our exclusive, Polyflex, face-forming ethyl carbamate material that allows the inner frame to form to most face shapes, creating a good seal while eliminating virtually any pressure points.

Rich Taylor didn’t win any Supercrosses or Nationals, but he made a living racing motocross and Supercross and through his test riding for Honda (and Suzuki) and strategically seeking out money races all over the world.

Rich Taylor didn’t win any Supercrosses or Nationals, but he made a living racing motocross and Supercross and through his test riding for Honda (and Suzuki) and strategically seeking out money races all over the world.

THE LENS IS ALSO VERY EASY TO CHANGE, TOO. The Lucid “Wavelatch” lens-locking system is one of my favorite aspects of this goggle, since we are installing new lenses often and it’s so much easier now. The locking system keeps the lens held and sealed tight while allowing the rider to quickly change lens tints with just the slide of their thumb. In my opinion, it’s the easiest lens to change on the market.

IS IT DIFFICULT TO MAKE EVERYONE HAPPY WITH ONE GOGGLE? No goggle will fit everyone perfectly, but we are really proud of the Lucid goggle. The Lucid 3D molded, multi-layer, 20mm-thick face foam fits nearly every face shape. The foam’s third layer of neoprene, along with our innovative new moisture channel that is molded into the goggle frame, also keeps sweat from dripping or splashing onto the goggle lens. This sweat gutter allows the sweat to run down the sides of the frame rather than into your eyes. Plus, the Lucid goggle offers one of the widest fields of vision available, which allows the goggle to use a 45mm-wide roll-off system. It took a long time to develop, but it has been a big success for us now.

Comments are closed.