MOTO PHYSICS: EVERYTHING YOU NEED TO KNOW ABOUT HIGH-COMPRESSION PISTONS

Bumping up the compression in your engine should be an informed decision. It’s important to first understand what effects high-compression has, the anatomy of a high-compression piston and what applications typically benefit most.</strong>By Paul Olesen

High-compression pistons are a common upgrade for dirt bikes and other motorcycles, but bumping up compression isn’t always beneficial. MXA takes a look at what effects higher compression has, designing high-compression pistons and what factors to address when considering adding one.

Whether you are racing or looking for increased performance out on the trail, there are a plethora of performance upgrades to consider to increase the power of your machine. Piston manufacturers, like JE Pistons, offer high-compression pistons for many applications, but there are important benefits and drawbacks you should consider when deciding if a high-compression piston is right for your application. We’ll take a look at what increasing compression ratio does and what effects it has on the engine, detail how high-compression pistons are made, and provide a high-level overview of which applications may benefit from utilizing a high-compression piston.

THERE ARE LIMITS TO HOW MUCH THE MIXTURE CAN BE COMPRESSED PRIOR TO COMBUSTION. IF THE TEMPERATURE OF THE MIXTURE INCREASES TOO MUCH BEFORE THE FIRING OF THE SPARK PLUG, THE MIXTURE CAN AUTO IGNITE.

How does an increased compression ratio affect engine performance? To understand how increasing the compression ratio affects performance, we have to start with understanding what happens to the fuel/air mixture on the compression stroke. During the compression stroke, the fuel/air mixture is compressed, and due to thermodynamic laws, the compressed mixture increases in temperature and pressure. Compared to the compression of a stock ratio, the fuel/air mixture is compressed more, resulting in increased temperature and pressure before the combustion event.

Higher compression, as on this JE piston, allows for a larger amount of fuel/air mixture to be successfully combusted, ultimately resulting in more power produced during the power stroke.

Higher compression, as on this JE piston, allows for a larger amount of fuel/air mixture to be successfully combusted, ultimately resulting in more power produced during the power stroke.

Detonation and pre-ignition can spike cylinder pressure and temperature, causing damage and pitting on the piston crown. The resulting power that can be extracted from the combustion event is heavily dependent on the temperature and pressure of the fuel/air mixture prior to combustion. The temperature and pressure of the mixture before combustion influences the peak cylinder pressure during combustion, as well as the peak in-cylinder temperature. For thermodynamic reasons, increases in peak cylinder pressure and temperature during combustion will result in increased mechanical efficiency, the extraction of more work, and increased power during the power stroke. In summary, the more the fuel/air mixture can be compressed before combustion, the more energy can be extracted from it.

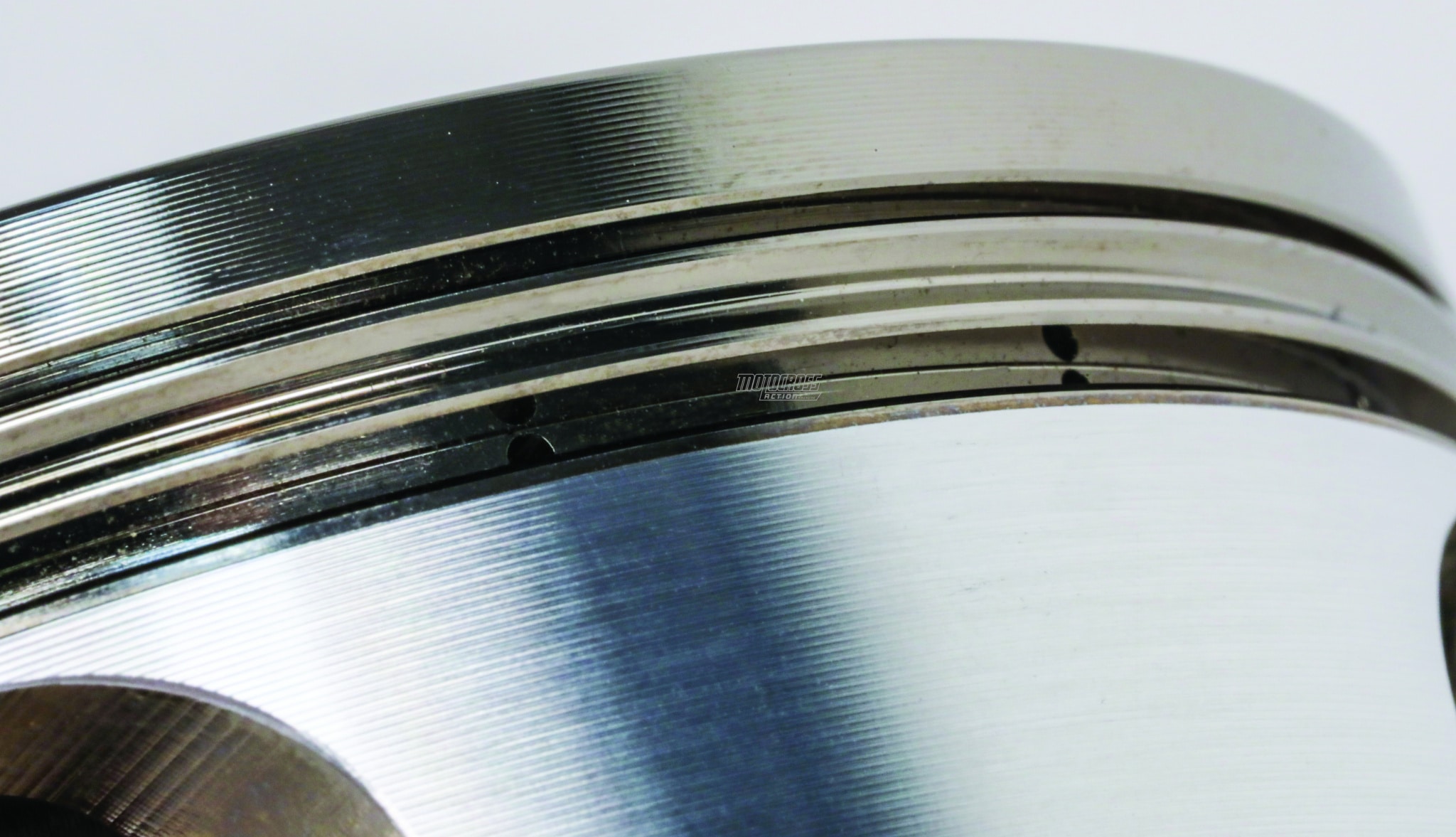

Surface treatments can protect the piston crown and ring grooves from potential damage caused by high-cylinder pressure and temperature. JE’s EN plating can increase longevity in a high-compression race build.

There are, however, limits to how much the mixture can be compressed prior to combustion. If the temperature of the mixture increases too much before the firing of the spark plug, the mixture can auto ignite, which is often referred to as pre-ignition. Another detrimental combustion condition that can occur is called detonation. Detonation happens when remaining gases spontaneously ignite after the spark plug fires. Both conditions put severe mechanical stress on the engine because cylinder pressures far exceed what the engine was designed for, which can damage top-end components and negatively affect performance.

WHEN THE BIKE IS RIDDEN AT LOW SPEED, IN TIGHT CONDITIONS, OR WITH LOTS OF CLUTCH USE, THE ENGINE CAN BE NEGATIVELY IMPACTED BY THE INCORPORATION OF A HIGH-COMPRESSION PISTON.

Now that there is an understanding of what changes occur during combustion to deliver increased power, we can look at what other effects these changes have on the engine. Since cylinder pressure is increased, more stress is put on the engine. The amount of additional stress that is introduced is largely dependent on the overall engine setup. Since combustion temperatures increase with increased compression ratio, the engine must also dissipate more heat. If not adequately managed, increased temperatures can reduce the lifespan of top-end components.

High compression pistons increase the load on the working structure of the engine including the rings, piston itself and top end rod bearings.

Often, additional modifications can be made to help mitigate the side effects of increasing the compression ratio. To help reduce the risk of pre-ignition and detonation, using a fuel with a higher octane rating can be advantageous—think race gas. Altering the combustion event by increasing the amount of fuel (richening the mixture) and changing the ignition timing can also help—think bigger main and retarding the ignition. Cooling system improvement can be an effective way to combat the additional heat generated by the combustion event—think larger radiators, oil coolers, Boyesen water pumps or high-pressure radiator caps. Equipping the engine with a high-performance clutch can help reduce clutch slip and wear, which can occur due to the increased power—think Hinson or Rekluse.

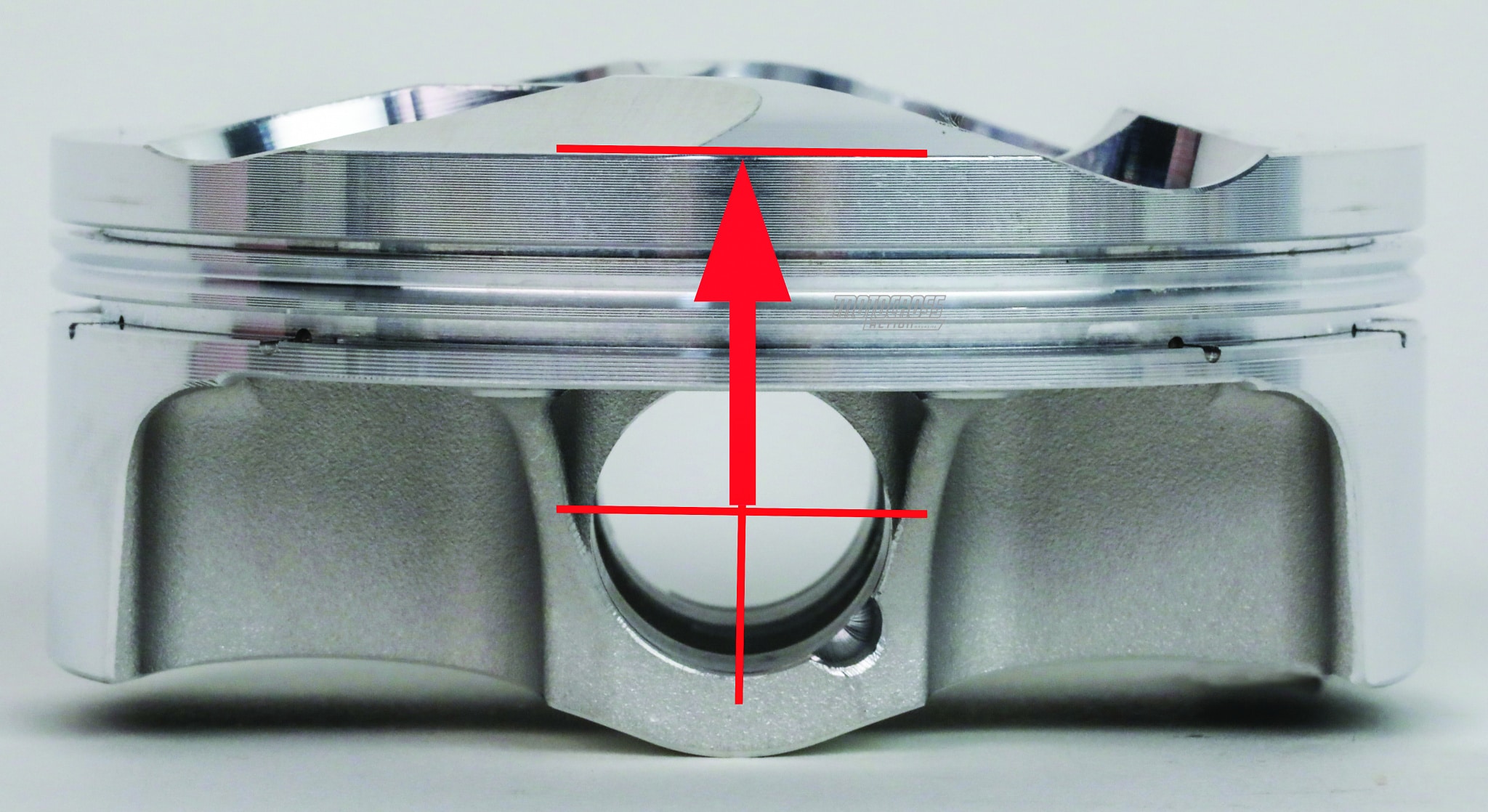

Higher compression is commonly achieved by increasing dome volume combined with raised features and deep valve pockets, as with this JE Piston.

Compression height can also be increased, which increases the distance between the center of the pin bore and the crown of the piston.Let’s take a quick look at what considerations are made when designing a high-compression piston. Typically, high-compression pistons are made by adding dome volume to the piston crown, which reduces the clearance volume at top dead center (TDC). In some cases, this is difficult to do, depending on the combustion chamber shape, size of the valves, or the amount of valve lift. When designing the dome, it is essential to opt for smooth dome designs. Smooth domes, as opposed to more aggressively ridged designs, are preferred because the latter can result in hot spots on the piston crown, which can lead to pre-ignition. Another common design option is to increase the compression distance, which is the distance from the center of the wrist pin bore to the crown of the piston. In this approach, the squish clearance, which is the clearance between the piston and head, is reduced.

From left to right: 13.0:1, 13.5:1 and 14.0:1 compression ratio pistons, all for a YZ250F. Notice the differences in piston dome volume and design.

A high-level overview of which applications can benefit from an increased compression ratio can be helpful when assessing whether a high-compression upgrade is a good choice for your machine. Since increasing the compression ratio increases power and heat output, applications that benefit from the additional power and can cope with the additional heat realize the most significant performance gains. On the other hand, applications where the bike is ridden at low speed, in tight conditions, or with lots of clutch use can be negatively impacted by the incorporation of a high-compression piston. Keep in mind, these statements are generalizations, and every engine responds differently to increased compression ratios.

Fortunately, if you’re considering increasing your engine’s compression ratio by utilizing a high-compression piston, many aftermarket designs have been tested and optimized for specific engines and fuel octane ratings. For example, most piston manufacturers offer pistons at incrementally increased compression ratios so that you can incorporate a setup that works best for you. For example, JE high-compression pistons for off-road bikes are commonly available in 0.5 compression ratio increases. If an engine’s stock compression ratio is 13.0:1, there will most likely be options of 13.5:1 and 14.0:1, so that you can make an informed decision on how much compression will benefit you based on your machine and type of riding.

Even if stock compression is better for your application, the forged construction, stronger skirt designs and more efficient crown designs of aftermarket pistons can still provide improved performance and durability.

If performance is sufficient at an engine’s stock compression ratio, there are still improvements in efficiency and durability that can be made with a forged piston. Forged pistons have a better aligned alloy grain flow than cast pistons, creating a stronger part more resistant to the stresses of engine operation. In addition to forged material, improvements can be made on piston skirt style designs to increase strength over stock designs, such as with JE’s FSR designs. Piston designers also commonly address dome design on stock compression pistons, employing smoothness across valve reliefs, edges and other crown features to improve flame travel, decrease hot spots, and ultimately increase the engine’s efficiency.

Comments are closed.