MWR | FC450 DYNO RUN, DUST STORM, TRICK YZ250

#WHIPITWEDNESDAY

#WHIPITWEDNESDAY

Rider: Ryan Dungey

Bike: 2009 Suzuki RM-Z250

Event: 2009 Anaheim 1

Photographer: MXA Archives

Lens: 70-200mm f/2.8

Focal length: 170mm

Exposure: 1/800sec

F-stop: f/4

ISO: 1600

TWO-STROKE SPOTLIGHT: TWO-STROKE SHOWS SIGN OF AFFECTION

“Hey guys. Been a subscriber since the early ’80s. I has been a two-stroke loyalist all my life. Not to long ago I went to put a new piston in my YZ250 and this is the response I got from her. You can say we have a good relationship. And to think I considered a four-stroke.” –Pete from Ottawa, Canada.

Editors Note: Please keep those submissions coming. If you would like your bike to be featured in the “Two-Stroke Spotlight,” please email me at [email protected]. All I ask is that you give a breakdown of your bike and a detailed description of the build. Please also send a few photos of your steed. By submitting your bike for the “Two-Stroke Spotlight,” you agree to release all ownership rights to the images and copy to MXA. Please don’t email me spam or try selling me Taylor Swift concert tickets or email me spam. Happy submitting your smoker.

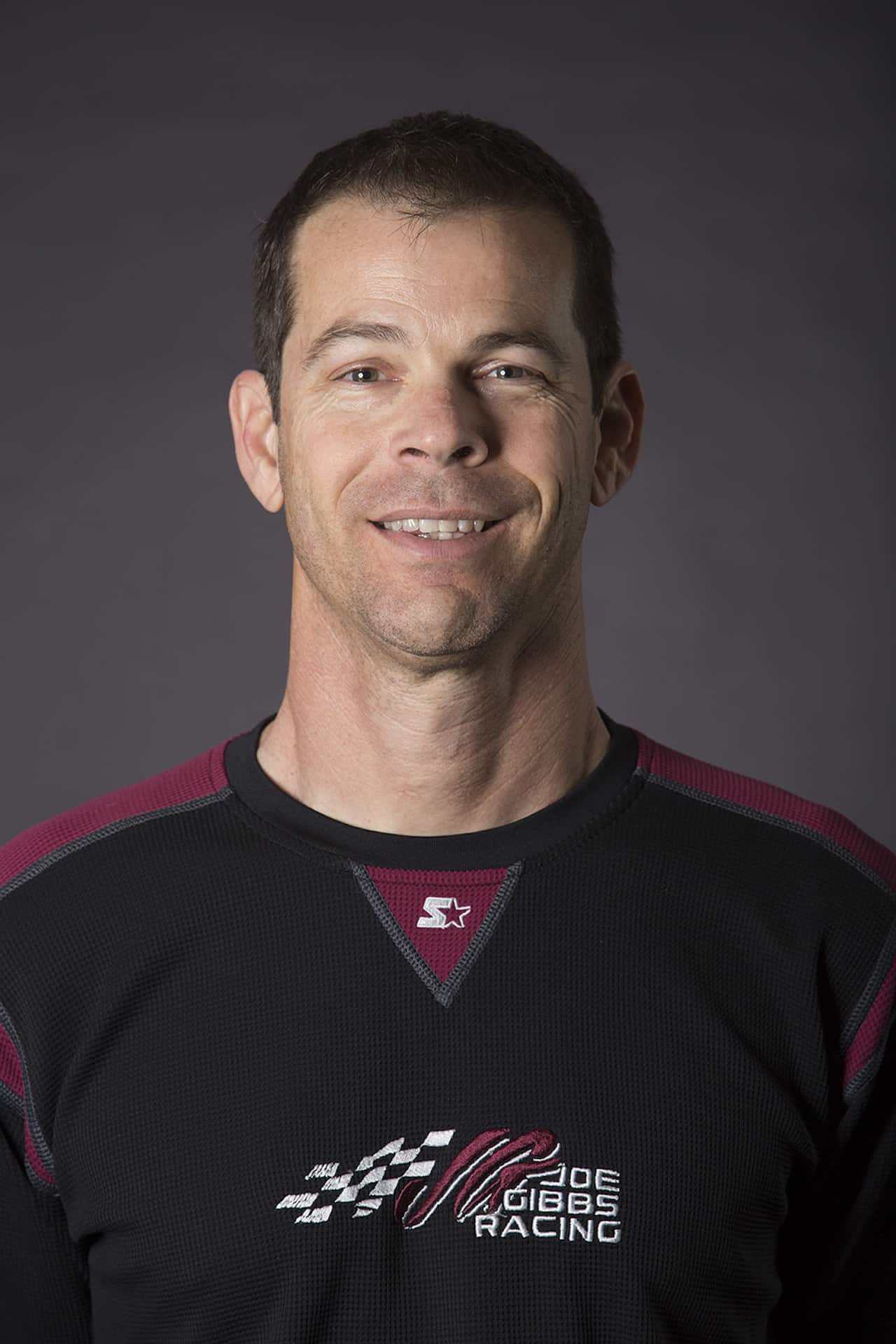

MINI-VIEW | JGRMX’s ENGINE TUNER DEAN BAKER

Dean Baker has been with the JGRMX race team since its inception at the end of 2007. The former racer, turned mechanic, turned engine tuner knows what it takes to get the most out a motorcycle’s powerplant. For that reason he has earned the catch phrase “Dean Baker the horsepower maker.” However, that doesn’t tell the whole story. Baker is talented in many ways and has been instrumental in the team’s success and growth. We sat down with Dean Baker to learn more about his path to JGRMX, his take on the advent of modern four-stroke development, the switch to electronic fuel injection, and many other topics.

DEAN, YOU WERE AN ACCOMPLISHED RACER. WHY THE DECISION TO STEP AWAY FROM RACING AND PURSUE A CAREER AS A MECHANIC? I ran out of talent and funding [laughter]. I was always really good at making sure that my own personal bike looked really good. I grew up with guys that rode the wheels off their bikes. They would show up to the races and their bikes looked like they were hammered. I always wanted my bike to look really nice. Perhaps that was detrimental to my potential as a racer. Eventually, when I got through my racing years, I went to college in an effort to figure out what I wanted to do with my life. I was moving in the direction of architecture. I had almost finished with my sophomore year and a buddy I knew through racing needed a mechanic. His name was Jeromy Buehl. I thought it would be something fun to do, because it would allow me to remain active in the racing community. It offered that competitiveness that I craved. I was immediately hooked. That first job as a mechanic grew into good opportunities each year along the way. My first official team job was with Honda of Troy in 1993. The following year I stayed on with them, and that turned into a ten-year run with that program.

YOU WERE AT YAMAHA OF TROY DURING THE ADVENT OF THE MODERN DAY FOUR-STROKE MOVEMENT IN WHAT IS NOW KNOWN AS THE 250 CLASS. WAS IT CHALLENGING TO LEARN THE INNER WORKINGS OF THE FOUR-STROKES? I’m very fortunate to have had people throughout my career that have helped me along the way. There was Phil Alderton at Honda of Troy, which then morphed into Yamaha of Troy, along with team manager Erik Kehoe. Steve Butler and Bob Oliver from Yamaha were instrumental. Those two guys really gave me so many responsibilities and duties with the engines. I had transitioned from a mechanic—someone who was working on the bike and not working on engines—to the complete opposite. I was porting, machining heads, and things like that. I had to learn a lot in order to broaden my skill set. Steve and Bob provided the necessary lessons, and they also gave me only as much as I could handle. I grew at my pace, and I’d like to think that I picked things up quickly and moved on to the next project. In hindsight, I could have pushed harder and done some new things with the four-strokes early on, but you can’t change history.

SPEAKING OF HISTORY, HOW QUICKLY DID YOU UNDERSTAND THAT FOUR-STROKES WOULD SURPASS TWO-STROKES IN PROFESSIONAL RACING CIRCLES? I would like to say that I knew right away, only because of what we know now. However, I knew once I put a four-stroke on the dyno and saw the numbers. The power spread was incredible. Initially, we raced both two-strokes and four-strokes at Yamaha of Troy. I could see that if a rider rode a two-stroke really well, then he could remain competitive. Conversely, you could take that same rider and put him on a four-stroke and he could go faster, just as long as he adapted his riding style to the four-stroke.

WAS IT A DIFFICULT DECISION IN CHOOSING TO UPROOT YOUR FAMILY AND MOVE FROM SOUTHERN CALIFORNIA TO NORTH CAROLINA AND WORK FOR JGRMX? It was a fairly easy decision, but I’ll admit that I pushed the opportunity aside for a little bit. That’s because I had just started at KTM. From Yamaha of Troy I moved to Factory Kawasaki for three years. Then I had a short stint at KTM. I was there for less than half of a year. I had worked with Jeremy [Albrecht, team manager] at Factory Kawasaki. He mentioned that Joe Gibbs Racing was starting a motocross team, and he wanted to know if I was interested. I was happy at KTM, but my family has and always will come first. My family is from the East Coast, and I always wanted my kids to grow up knowing their extended family. It wasn’t strictly because of family, but I had long thought about taking that next step. Joe Gibbs Racing is a great organization, and I thought that it was what I needed. I met with them and was immediately convinced that it was the right direction to go.

WHAT HAS BEEN THE BIGGEST CHANGE YOU HAVE NOTICED IN THE PAST TEN YEARS AT JGRMX? We have grown so much in our capabilities. When we first started as a team, the JGR Cup shop told us that they had all of the necessary tools, but we didn’t have the connections with the people to get things done. Of course, we have some people on the team that are very talented at fabrication, welding, and things of that sort. Spencer [Bloomer] can design, cut and weld anything. Everybody has their skill sets to get things done. I’ve learned that you can’t do everything yourself, though. Over the course of the years we’ve been able to mesh more and more with the JGR Cup shop. That way we can utilize our assets more. The team continues to acquire personnel that have unique skills, and those talents help drive us forward. We’re not just a group of guys that change the oil and tighten some bolts. Everyone has to wear multiple hats.

THE SWITCH FROM CARBURETORS TO ELECTRONIC FUEL INJECTION (EFI) IN MOTOCROSS ISN’T BIG NEWS ANYMORE, BUT IT WAS REVOLUTIONARY AT THE TIME. WAS IT CHALLENGING TO ADAPT TO? Grasping the concept of the mapping–not so much electronically–but learning what was actually in the map was challenging. Figuring out the tables and what those values meant was interesting to me. We were actually on the last bike that had the carburetor. For a while I battled against EFI. I believed I could jet a carburetor as well as anyone could map a bike. Then, as soon as we got the EFI bike, we could see the benefits from the start. Mapping is only as good as the person doing it, just like with a carburetor. Mapping added another layer of tuning, and another full-time job!

THE TEAM SWITCHED TO SUZUKI QUITE LATE IN THE OFFSEASON PRIOR TO 2017. EXPLAIN THOSE FEW SHORT MONTHS BEFORE THE SUPERCROSS SERIES KICKED OFF. It was hectic! I’d be lying if I said that it was easy. It took everyone going wide open in order to do what was necessary to make things happen. We were lucky in that we were only supported lightly by Suzuki at that time. There weren’t huge expectations by Suzuki to carry the flag. It was good that we didn’t have the extra pressure. The funny thing is that every offseason there’s a lot of work to be done. Going back a bit, we had some experience with the Suzuki RM-Z450 in 2012 with Butler Brothers Racing. Given that it was five years prior, it didn’t help us too much with development. However, the engine fixture for our engine dyno had already been fabricated. There were a few small things that helped get us off the ground.

FOR 2018, THE TEAM IS FIELDING A FOUR-RIDER 250 EFFORT. YOU’RE SPEARHEADING ENGINE DEVELOPMENT FOR THE RM-Z250. WHAT HAVE YOU LEARNED? Yoshimura had a year’s worth of development on that engine, as far as the whole package is concerned. People sometimes forget that the engine is connected to all of these other systems, whether it’s the ECU, throttle body, or airbox. When you look at it as a whole unit there’s a whole lot more than just working on the engine. Yoshimura did a very good job at getting the bike to the performance level that it was at. I definitely felt that it was going to be difficult to make it even better. However, if you can give the riders any improvement in any way, that will make them happy. I knew that we could make gains, but I thought it would be a little bit easier than it has been. In the last month we’ve made really nice gains. The riders seem excited about where we’re at, especially compared to last year. It has been a bit stressful, that’s for sure. There was some head scratching and nervousness, but I think we got to the other side in good shape. Now we have to go race.

THE 250 BIKES HAVE HOLES IN THE AIRBOX AND CUT SEATS. WHAT IS THE REASONING BEHIND THOSE MODIFICATIONS? It’s all about feeding the engine as much air as we can, and doing it the right way. There are a lot of things you can do to those parts, whether it’s the airbox, fender or seat. You can drill holes wherever you might think would be good, but it might not necessarily be good for the engine. I’m fortunate to have the tools available to me that we can be sure that the performance is enhanced by what we’ve done, versus relying on the riders at the track. It eliminates outside influences, such as the rider believing the engine is faster because with the holes the bike is louder. Seat of the pants testing is a good indicator that things are improved, but the dyno proves what we see at the track.

PLEASE TALK ABOUT THE DIFFERENT ENGINE DYNOS THAT YOU USE. We have access to two different dynos. The engine dyno runs straight off the countershaft sprocket. It tends to be more sensitive to changes on the engine, so we can be more critical, as opposed to the rolling dyno. Having said that, the rolling dyno has its positives. You can argue that it’s more of a real-life situation. You can roll the throttle on. Conversely, there are some outliers that you have to take into account. You’re dealing with the drive train, so maybe it has different lubrication over the course of the day. Chain tension and tire pressure also influence the results. The engine dyno eliminates all of those variables. Each dyno has its positives. It’s beneficial to have both. We utilize them the best way we can so we can bring performance to the track.

BRIEFLY EXPLAIN THE TEAM’S ENGINE PROCEDURES. Every engine is put on the dyno–whether it’s a practice engine, race engine, or a prototype. We definitely want to know what the performance level is, and then back that up with rider impressions at the track. It’s also a good way to run the engine initially and know that it’s sound. As far as engine lifespan, we make sure that nothing in the engine is beyond ten hours of run time. That doesn’t mean the engine cases will be thrown in the trash. Some of those parts will be demoted to practice engines so that we can utilize the full lifespan of those parts. We keep the race engines fresh. We have a budget for parts, and we want to avoid any problems. At the same time, we need to prove out the durability of those parts. On the practice bikes we run engines with parts that might go 20 hours before getting changed out. We service 250 race engines every two to three hours, which could be two to three races in Supercross. On the 450 we service the race engines every three hours. Parts will be inspected, and other parts will be changed.

RIDE ENGINEERING PERFORMANCE LINK FOR 2018 RM-Z 450

Press Release: With most people trying to get the new 2018 RMZ450 balanced at 115mm of race sag with poor results, Ride Engineering has developed a longer linkage arm to provide a solution to this condition. With the Ride Link, race sag at 108mm and the fork height between 5 & 7mm, all test riders agreed the bike felt balanced, the tall sensation was reduced and with proper springs and valving, was ready to tackle the roughest track conditions. There was no longer an unpredictable feeling from the bike riding too low in the stroke, providing the rider much needed confidence to push. $209.95 www.ride-engineering.com or [email protected] (800) 805 1516.

Press Release: With most people trying to get the new 2018 RMZ450 balanced at 115mm of race sag with poor results, Ride Engineering has developed a longer linkage arm to provide a solution to this condition. With the Ride Link, race sag at 108mm and the fork height between 5 & 7mm, all test riders agreed the bike felt balanced, the tall sensation was reduced and with proper springs and valving, was ready to tackle the roughest track conditions. There was no longer an unpredictable feeling from the bike riding too low in the stroke, providing the rider much needed confidence to push. $209.95 www.ride-engineering.com or [email protected] (800) 805 1516.

DYNO RUN OF THE 2018 1/2 ROCKSTAR EDITION FC450

PRO CIRCUIT HONDA CRF250 EXHAUST

Press Release: Honda’s new 2018 CRF250R with dual headers and dual mufflers is in big demand and Pro Circuit has performance exhausts for the new Honda machine. Superior performance, and significant power gains are what’s on tap with both our Ti-6 and T-6 systems. Also, a T-6 slip-on silencer with removable spark arrestors is available. Pro Circuit has built its reputation on championship winning performance products and 2018 is no different. Equip your new Honda CRF250R with the latest Pro Circuit Ti-6 or T-6 exhaust system and leave your competition in the dust. Pro Circuit. We Race.

The Ti-6 Pro Titanium Exhaust System is designed for the AMA Pro racer competing in AMA/Monster Energy Supercross, Amsoil Arenacross or Lucas Oil Pro Motocross Championship series. Engineered to meet strict AMA/FIM sound regulations, the Ti-6 Pro system provides superior performance while complying with the series’ sound regulations. Ti-6 Pro exhaust system is constructed from high-grade titanium throughout with carbon fiber end-caps for a factory look. Top Pro level teams look to Pro Circuit for products that win.

The Ti-6 Titanium Exhaust System is designed for both closed-course and off-road racers. It’s the ideal system for AMA Amateur events or any rider or racer looking for winning performance, legendary durability and a professional look. The Pro Circuit Ti-6 System is equipped with removable USFS approved spark arrestors, making it easy to alternate between off-road and closed-course racing.

The T-6 Stainless Steel Exhaust System is designed for both closed-course and off-road competition. Constructed from high strength stainless steel and aluminum, the T-6 offers the same improved performance as our Ti-6 System. The T-6 System is a great way for riders or racers looking for winning performance, legendary durability and a professional look but at a lower price. In addition, the T-6 System is equipped with removable USFS approved spark arrestors making it easy to alternate between off-road and closed-course racing.

The T-6 Stainless Steel Slip-On Silencer is for riders looking for an inexpensive, easy-to-install, durable performance silencer that can bolt right onto their stock head pipe. The T-6 Slip-On is constructed of stainless steel and high quality aluminum for increased durability. The T-6 Slip-On is a great option for any rider looking for an increase in performance on a small budget. Removable USFS approved spark arrestors are included to make it easier to alternate between off-road and closed-course racing. www.procircuit.com

WHAT THE MXA WRECKING CREW IS UP TO

Yesterday we got a date with the 2018-1/2 Rockstar Edition FC450. On the track this is an all around improved bike, although it has some bugs that we need to work out.

Yesterday we got a date with the 2018-1/2 Rockstar Edition FC450. On the track this is an all around improved bike, although it has some bugs that we need to work out.

We know it was going to be windy last Thursday at Glen Helen, but we have never seen wind like this before. We had to wait in between gusts in order to get the shoots. Test rider Justin Muscutt was a trooper for enduring the weather.

We know it was going to be windy last Thursday at Glen Helen, but we have never seen wind like this before. We had to wait in between gusts in order to get the shoots. Test rider Justin Muscutt was a trooper for enduring the weather.

Jay Clark brought his KTM 250SXF that he built for us out to the wind storm. Jay gives the okay.

Jay Clark brought his KTM 250SXF that he built for us out to the wind storm. Jay gives the okay.

Justin Muscutt kicks up some dust on Jay’s KTM 250SXF.

Justin Muscutt kicks up some dust on Jay’s KTM 250SXF.

We were lucky enough that former factory mechanic Jon Mitcheff let us test his YZ250 two-stroke beauty. It is a Pro Circuit built machine with trick one off stuff like Chad Reed’s old carbon fiber silencer. Look for a test on this bike in a future issue of MXA.

We were lucky enough that former factory mechanic Jon Mitcheff let us test his YZ250 two-stroke beauty. It is a Pro Circuit built machine with trick one off stuff like Chad Reed’s old carbon fiber silencer. Look for a test on this bike in a future issue of MXA.

We timed the gust at the wrong moment. This gust knocked Daryl who took the photo on his butt when it reached him.

We timed the gust at the wrong moment. This gust knocked Daryl who took the photo on his butt when it reached him.

Jon Mitcheff’s bike in action.

Jon Mitcheff’s bike in action.

SUBSCRIBE TODAY TO DIGITAL & PRINT TO MAKE MONEY ON THE DEAL

JOIN MXA’S SNAP CHAT FEED

If you are a Snap Chat user then add us to your stories. Get sneak peaks of everything moto. Our Snap Chat name is motocrossaction. Or just take a Snap of the picture above and it will add MXA automatically to your feed.

If you are a Snap Chat user then add us to your stories. Get sneak peaks of everything moto. Our Snap Chat name is motocrossaction. Or just take a Snap of the picture above and it will add MXA automatically to your feed.

JERMEY MARTIN TO RACE THE FIRST 3 SUPERCROSS ROUNDS ON CRF450

During a media event at Honda’s private test track, American Honda announced that Geico Honda rider Jeremy Martin will compete in the 450SX class aboard a CRF450 at the first three rounds of the 2018 AMA Supercross series. The arrangement is an example of the opportunities allowed by the close working relationship between Team Honda HRC and Geico Honda.

While competing in last year’s 250SX West Region Championship, Martin substituted for the then-injured Ken Roczen in the 450SX class at the Daytona Supercross, finishing an impressive second in the main event. The Minnesota native’s primary focus this season is the 250SX East Region Championship, which he will campaign alongside fellow Geico Honda riders RJ Hampshire and Cameron McAdoo, but Martin and Honda agreed that it would be beneficial for him to accumulate some racing experience before that series commences on February 17 in Arlington, Texas.

For the first three rounds (Anaheim 1 on January 6, Houston on January 13, and Anaheim 2 on January 20), Martin will race a factory 2018 CRF450 out of the Geico Honda pit, alongside 250SX West Region riders Christian Craig and Chase Sexton. As usual, Roczen and Cole Seely will pit out of the Team Honda HRC truck.

Jeremy Martin: “I’m extremely excited to be lining up on the gate at Anaheim 1 on a factory Honda. I really enjoyed riding in the 450SX class at Daytona last year and having some success with the team, so I’m looking forward to building on that at the first three rounds of supercross. I plan to take full advantage of this opportunity and show what I’m capable of. It will also be a good chance to get some gate drops in before I start the 250SX East Region series in Arlington.”

Jeremy Martin: “I’m extremely excited to be lining up on the gate at Anaheim 1 on a factory Honda. I really enjoyed riding in the 450SX class at Daytona last year and having some success with the team, so I’m looking forward to building on that at the first three rounds of supercross. I plan to take full advantage of this opportunity and show what I’m capable of. It will also be a good chance to get some gate drops in before I start the 250SX East Region series in Arlington.”

Erik Kehoe: “We’re looking forward to seeing Jeremy on the CRF450R for the first three rounds of the season. He’s a very determined racer, and he did such a good job filling in on a 450 last year that when he asked if he could get his feet wet on the big bike, we were proud to be able to honor that request. GEICO Honda’s program is an extension of Team Honda HRC, and the fact that we work together so closely facilitates taking advantage of opportunities like this.”

Erik Kehoe: “We’re looking forward to seeing Jeremy on the CRF450R for the first three rounds of the season. He’s a very determined racer, and he did such a good job filling in on a 450 last year that when he asked if he could get his feet wet on the big bike, we were proud to be able to honor that request. GEICO Honda’s program is an extension of Team Honda HRC, and the fact that we work together so closely facilitates taking advantage of opportunities like this.”

Dan Betley: “We’re excited about Jeremy’s potential this year, and based on his performance during the off-season, we expect him to be a contender for the 250SX East Region Championship. He approached us about getting in some races on the 450, and we agreed that competing in a few 450SX rounds would be a good way for him to be as prepared as possible ahead of Arlington, especially considering the chassis similarities between the two bikes.”

Dan Betley: “We’re excited about Jeremy’s potential this year, and based on his performance during the off-season, we expect him to be a contender for the 250SX East Region Championship. He approached us about getting in some races on the 450, and we agreed that competing in a few 450SX rounds would be a good way for him to be as prepared as possible ahead of Arlington, especially considering the chassis similarities between the two bikes.”

TALK MOTO WITH MOTO MINDED PEOPLE. JOIN MXA’S FACEBOOK GROUP CHAT

We love everything moto and want to bring all moto junkies together into one place to share their two cents, ideas, photos, bike fixes, bike problems and much more. To check it out first you must need to or already have a Facebook account. If you don’t, it isn’t much work and you could even have an alias so nobody knows it is you. To join click HERE. After you request to join we will accept your request shortly after.

We love everything moto and want to bring all moto junkies together into one place to share their two cents, ideas, photos, bike fixes, bike problems and much more. To check it out first you must need to or already have a Facebook account. If you don’t, it isn’t much work and you could even have an alias so nobody knows it is you. To join click HERE. After you request to join we will accept your request shortly after.

CLASSIC PHOTO

Remember when Two Brothers Racing built James Stewart a 24K gold-plated Kawasaki ZX-636?

Remember when Two Brothers Racing built James Stewart a 24K gold-plated Kawasaki ZX-636?

Comments are closed.