MXA TECH SPEC: MAKE IT COOL, SO YOU CAN MAKE IT HOT

A motocross engine, like all internal combustion engines, is a heat generator. Heat is more than a byproduct of horsepower; it is the product! The more heat is generated, the more power is produced, but this same heat is attracted to the working parts in a negative way. When there is a heavy load, the cooling system must absorb the heat as it builds up. If the parts are allowed to become overheated, the engine could slow down or stop running entirely.

A cooling system consists of fluid, a water pump, radiators, hoses and clamps (not to mention water passages throughout the cases, cylinder and head). Obviously, if you overbuild the radiators, fluid capacity, pump volume and hoses, you could keep the engine as cool as a block of ice‚ but it would come at a hefty price in weight. That is why motocross bike designers try to make each part no part bigger than necessary and no part smaller than required.

The most important piece of the engine-cooling puzzle is the flow rate of the fluid. For years, engine tuners believed that the coolant must flow at a rate slow enough for the fluid to draw heat out of the cylinder and head while keeping the fluid in the radiators long enough for the heat to dissipate via convection cooling. It sounds logical, but there is such a thing as too slow. And even though the idea of slowing the fluid flow down is widely accepted, it is wrong. In fact, the faster the flow rate, the more efficient the cooling system. How so? The greater the temperature difference between the liquid and the metal, the greater the rate of heat transfer. Think about that? If the cylinder is hot and the water is cold, the cooling system picks up the heat more efficiently and carries it out of the engine faster (to the radiators). Thus, the higher the fluid speed, the more BTUs of heat are removed from the metal surfaces.

You might ask, doesn’t the higher fluid speed mean that the hot water will have less time to be cooled off in the radiators? Yes, the water will spend less time in the radiators, but it will not stay hot. Higher fluid speed means greater pressure in the radiators, which pushes the fluid through the radiator tubes at an even higher velocity. The higher velocity creates more fluid turbulence. The combination of high pressure, high velocity and high turbulence exposes more heated molecules to the heat-exchange surface of the radiators. That means that faster fluid rates create superior heat transfer in radiators.

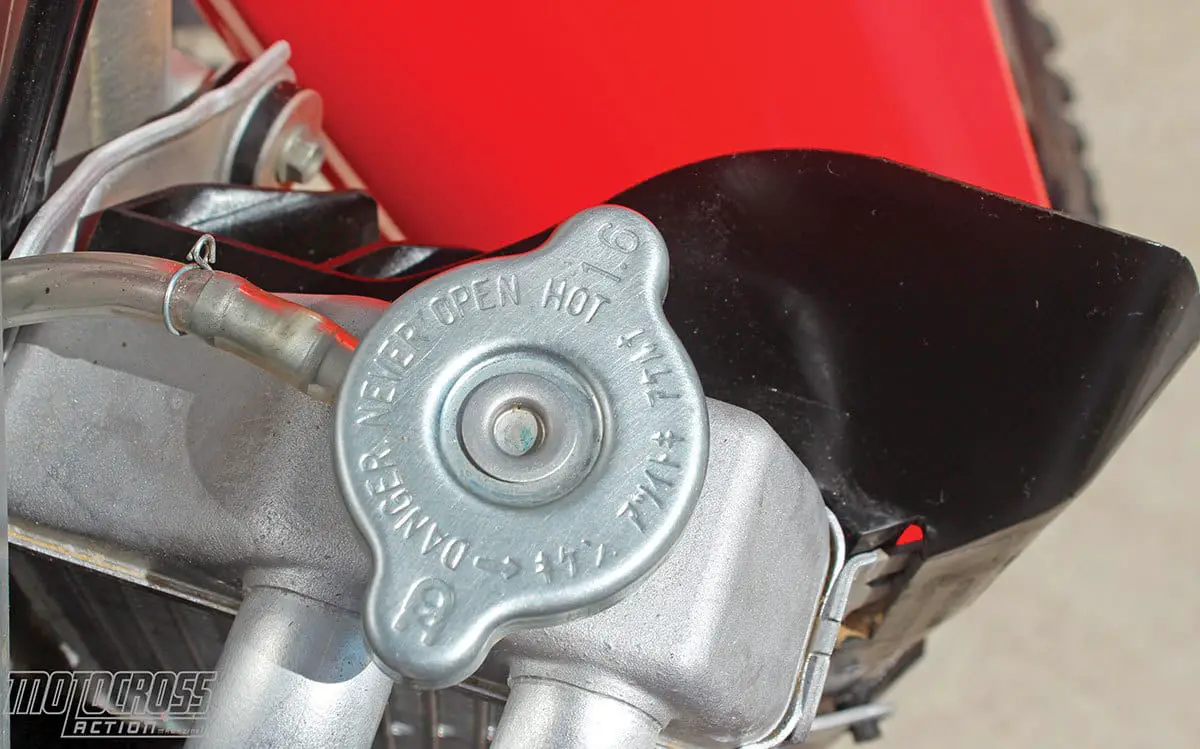

FOR EVERY POUND OF PRESSURE EXERTED ON THE COOLANT BY THE RADIATOR CAP, THE STATIC BOILING POINT IS RAISED BY 3 DEGREES. MANY MODERN BIKES COME WITH 1.1 KG/MM2 RADIATOR CAPS, BUT KTMS COME WITH A 1.8 KG/MM2 CAP.

The design of the cooling system’s working parts affects its cooling ability. Motocross water pumps use a centrifugal design with an impeller‚ much like the paddle wheel on a steamboat. As the impeller rotates, it pushes water through the engine. The rotating impeller is housed in a tight-fitting, Nautilus-shaped plenum that guides the fluid out of the pump. A centrifugal water pump can move a fair amount of fluid, but its ability to generate a high flow rate is very limited.

Water, the most commonly used fluid, is a good conductor of heat. Water does have one significant drawback, though. Its boiling point is only 212 degrees Fahrenheit. This is lower than the operating temperature of a high-performance race engine. So why doesn’t it boil over? The water doesn’t boil because it is pressurized by a radiator cap. Radiator caps that pressurize the water with 15 pounds of pressure will stop the water from boiling until it reaches 250 degrees. When you pressurize a 50/50 mix of water and antifreeze to 15 pounds, it won’t boil until it reaches 280 degrees. For every pound of pressure exerted on the coolant by the radiator cap, the static boiling point is raised by 3 degrees. Many modern bikes come with 1.1 kg/mm2 radiator caps. Kawasaki uses a 1.6 cap, and KTMs come with a 1.8 kg/mm2 cap. A 1.1 kg/cm2 cap can handle 14.22 psi before the coolant pushes the valve open and steam comes out of the overflow. By increasing the radiator cap to 1.8, the radiator can handle 25.6 psi, while a 2.0 cap ups the ante to 28.45 pounds. The higher the pressure, the longer the water in your radiator resists boiling.

The current trend on the AMA circuit is to remove the water pump and impeller and replace it with an inline electric water pump that is hooked to the bike’s electrical system. The big advantage of an electric water pump is that it doesn’t have shafts, seals or impellers creating drag on the engine. It takes power to make power. Have you ever been driving down the highway at 70 mph only to turn your pickup’s air conditioner on and have your speed drop slightly? Sure you have. Do you know why? The air conditioner’s compressor steals about 3 horsepower every time you turn it on. The same is true of your motocross bike’s impeller-driven water pump. Additionally, when you slow down, the impeller spins slower also. The modern water pump reduces horsepower and doesn’t maintain a consistently high fluid speed. An electric water pump does not steal power from the engine and consistently maintains a high flow rate regardless of the engine’s rpm. Electric water pumps are the future of motocross cooling systems.

Comments are closed.