SEARCHING FOR THE ULTIMATE 2009 CRF450 CLUTCH SYSTEM:

Be careful what you wish for. There isn’t a motocross racer alive who doesn’t wish that he could have a works bike…preferably a works Honda CRF450. So, when Honda’s test department was prototyping the 2009 Honda CRF450, they decided to steal the works clutch from the race bikes of Millsaps, Short, Townley and Tedesco. The works clutch, which Team Honda has been using secretly for the last several race seasons, is a trimmed down, lightened up, minimalistic design that lessens rotating mass and inertial forces on the working parts of the clutch. The key differences between Honda’s works clutch and all previous clutches is that Honda’s engineers saved weight by lessening the number of springs in the unit. And what springs they did keep, they traded for high-end, high-priced titanium coils. The secret clutch had been bulletproof in the hands of the race team and would be icing on the cake of Honda’s 2009 flagship motocross bike.

The only fly in the ointment is that the transfer of this technology from the works bikes to the production bikes hit a few snags. Three to be exact.

(1) Maintenance. The four-spring Team Honda clutch never gets used for longer than one race (and often one heat or moto). Factory riders get a new clutch for every race, thus they don’t care about the work cycle of their clutches. Consumers, on the other hand, aren’t as likely to throw $80 worth of clutch plates into their engines every weekend. The works part is cool, but it is kept cool by the works mechanic and an unlimited parts budget.

(2) Springs. To make the four clutch springs work as well as the previous six clutch springs, the four springs had to be stiffer. When Honda’s engineers tried to match the clamping pressure of the 2008 six-spring clutch with the 2009 four-spring clutch, they discovered that no one could pull the lever in. It was too stiff. To keep the four-spring clutch, Honda had to make a compromise. Either they had to pony up for the ultra-trick titanium clutch springs that Team Honda was using (the price was out of their budget) or lower the spring rates of the four steel springs (and sacrifice clutch-pack pressure in the process)…they were between a rock and a hard-to-pull place.

When you use fewer clutch springs, they have to be stiffer than when you use more, but Honda decided not to go as stiff as required to insure solid hookup (or even enough to equal the clamping force of the previous six-spring clutch). And even though each individual 2009 clutch spring is stiffer than last year’s clutch springs, the new 2009 clutch has about 35 pounds less clamping force (plate-to-plate). Thus, with even a small amount of wear or age, the 2009 four-spring clutch is more prone to slipping than the 2008 six-spring clutch. This is a fact (a mechanical fact) that even the most loyal Honda owner will face if he uses the clutch hard.

(3) Materials. Team Honda has their four-spring works clutches built for them by Hinson Clutch Components. No surprise there. Virtually every AMA Pro runs Hinson clutches. Hinson CNC-machines every clutch basket, pressure plate and inner hub by hand. Hinson not only uses aircraft-quality billet aluminum, but they hard coat the aluminum with a special process that lessens wear over the long haul. For Honda’s production line machinery, the idea of CNC-machined billet clutches wasn’t in the cards. The demands of mass production called for cast aluminum pieces and their inherent disadvantages over the works parts. Every hardcore motocross racer knows what banging clutch plates can do to the tangs of a stock clutch basket, and while Honda’s production parts are light years stronger than they were a few years ago, they can’t match custom-made billet parts. As a result of the test department’s desire to deliver works technology to the consumers, the 2009 Honda CRF450 clutch is high-maintenance, fickle and exceptionally prone to slippage (in the hands of clutch abusers).

WHO NEEDS TO WIORRY ABOUT THE 2009-2010 CRF450 CLUTCH?

There is no doubt that the 2009 Honda CRF450 clutch works well enough to be considered race-ready (and Honda hasn’t announced any changes to the clutch for the 2010 CRF450–although they did put a five-spring clutch in the 2010 CRF250). If you are among the minority of racers who have forgotten all the clutch slipping tricks that you learned on two-strokes, you won’t have any immediate issues. But, you will have clutch issues sooner than you used to have, because, no matter how you cut it, less clamping pressure on the clutch plates is the fast track to eventual clutch slippage. If, however, you use your bike’s clutch as part of your riding style (slipping it to stay a gear higher, pumping it to add snap on acceleration or pulling it in to avoid flame out), you will experience clutch woes much sooner than non-clutch abusers.

When people tell you that “the best way to save your clutch is to not use it,” that is just plain stupidity. It is obvious that if you don’t use the clutch it will last forever, and the same goes for tires, gasoline and pistons. But is it a good idea to avoid riding your bike to save gas? If you are a rider who is very light on your clutch usage, then you will not have issues with the 2009 CRF450 clutch. If, however, you are like most racers and use the clutch, then you will eventually be interested in MXA’s 2009 clutch tips. Maybe not today, maybe not to tomorrow, but eventually, you will be pursuing one of MXA‘s four solutions.

We don’t like it. Yes, it works, but without expensive maintenance it won’t work for long. If you have the money to feed it clutch plates at regular intervals, it will work well, but clutch-for-clutch the 2009 clutch is not as reliable as the 2008 clutch. In our opinion, this is a step backwards for clutch users and abusers and not a good value for consumers. On a side note, when the clutch on a fuel-injected bike starts slipping, the danger of flame out goes up. Why? If the clutch doesn’t engage fully in a corner when pulled in, the bike will chug at low speed. Chugging is a large part of the flame-out picture (and when a clutch slips, a high idle speed cannot stop chugging).

MXA has provided you with several clutch solutions, but to make the nay sayers happy, we want to leave you with this advice: The easiest fix for the CRF450 clutch is to just not use it. For more info about 2009 Honda CRF450 clutches, contact Hinson Racing at www.hinsonracing.com or at (909) 946-2942.

THE CHEAP AND EASY FIX

When it comes to clutches, there are always cheap and easy fixes. In the old two-stroke days, savvy riders carried spark plug washers and automatic transmission fluid (ATF) with them in case of clutch problems. Today, ATF is out of the question, but spark plug washers still hold some hope. Rather than use spark plug washers as shims, the MXA wrecking crew had 0.060-inch shims machined. We stuck these shims under the four stock CRF450 clutch springs to preload them. By putting more load on the spring, we upped the pressure of their initial bite against the plates. It is a time-tested trick that almost always helps a slipping clutch.

Unfortunately, Honda’s clutch springs seem to be on the edge, and shimming them not only made them stiffer initially, but it turned them into light switches. Instead of firming up the clutch pack so that test riders could meter the feel, the clutch was either on or off. We rejected shimming as a solution. As a corollary, the 0.060-inch shims made the clutch hard to pull (perhaps we could have used 0.040-inch shims, but we were trying to get as much clamping pressure as possible).

The next fix was much better. We simply replaced the stock clutch spring with specially wound Hinson, Barnett or Pro Circuit clutch springs. They were stiffer, and the coils were wound to provide the most progressive modulation possible. By exchanging the four stock springs for four stiffer springs, the clamping pressure is increased (and so is the pull at the lever).

UPGRADING THE FOUR-SPRING MATERIALS

With the reduced clamping pressure of the 2009 CRF450 clutch, going to four stiffer clutch springs was the bare bones fix. The inherent problem is that stiffer springs mean a sigificant increase in clutch pull. This is no problem for a rider who raced a Maico, CZ or BSA, but modern marketing techniques have favored showroom usability over racetrack performance. The easier the clutch is to pull on the showroom floor, the more likely the buyer is to plunk down his cash. The connundrum of trying to build a works-style clutch (with the light weight of four springs and a reduction in their supporting mass) was that, without the ability to use the exotic titanium springs of the factory bikes, the spring pressure required to make the clutch bulletproof was too great for the showroom dog-and-pony show.

By adding four stiffer aftermarket clutch springs to the stock clutch you get better hookup, but you haven’t addressed all the other issues of clutch performance? issues that Team Honda found solutions to.

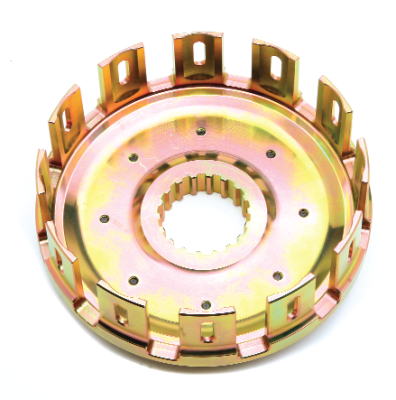

A local CRF450 racer can get closer to true-to-life works technology, by simply using all the CNC-machined parts that Hinson makes for Team Honda. The three basic parts are the clutch basket, pressure plate and inner hub (the only parts we couldn’t get that Team Honda uses were the titanium clutch springs).

In pure function, the Hinson replica of the stock 2009 Honda clutch layout was smooth in release and stiffer in pull. Those two characteristics were to be expected. Since the CNC-machined parts are stiffer and stronger, they flex less, reduce plate stiction and resist notching of the tangs. This allows the plates to move in and out with less friction. And the stiffer clutch springs increase the pack pressure (while making the clutch harder to pull in).

THE ULTIMATE PRIVATEER SOLUTION

The ultimate solution for MXA’s CRF450 clutch woes was to install a special Hinson six-spring clutch. We used a Hinson pressure plate, Hinson basket and Hinson inner hub (plus assorted Hinson hardware). This turned our new 2009 four-spring clutch into an exact replica of last year’s six-spring clutch. That worked wonders because it addressed all of the issues.

Now you might be wondering why you can’t just take last year’s stock six-spring 2008 Honda CRF450 clutch and stick it in the 2009 engine to replace the four-spring clucth. The reason you can’t is because it won’t fit. The 2009 clutch has a different spline size than the 2008 clutch.

On a positive note, the Hinson six-spring clutch can be installed by just changing the stock pressure plate and inner hub. The Hinson inner hub and pressure plate can be used with the stock CRF450 clutch basket (be sure and inspect the stock basket for notching). Or, you can order a complete Hinson six-spring clutch kit (basket, inner hub, springs and pressure plate).

Obviously, this fix is for riders who feel the need to improve the 2009 Honda CRF450 at all costs.

STEEL HAS ITS ADVOCATES??

In the process of testing a series of Honda clutch fixes, we decided to test Hinson’s unique steel clutch basket. CNC-machined out of a billet of solid steel, the Hinson steel basket weighs 2-1/2 pounds more than the stock cast aluminum basket.

We had our doubts about what effect this weight would have on the power curve of the 2009 CRF450, but since the CRF450 has so much low-end power on tap, we were hopeful that it would be beneficial.

Hinson makes the steel clutch basket for riders who never want to worry about the life-span of their clutch

baskets. The steel basket is extremely wear resistant, has oil ports to help lubricate the plates and improves clutch performance because of its stiction-free tangs.

The question wasn’t about clutch performance, because we expected an improvement in feel and action with the steel basket. The uncertainty centered around what the heavy basket would do to throttle response and power output. Amazingly, most MXA test riders liked the feel. At the worst, they felt that the heavy basket took the edge off of the harsher parts of the powerband and slowed the rev down in the midrange, but overall it wasn’t much of an issue. Perhaps, because of the direction of rotation of the clutch, it operates more as a giant counterbalancer than as a flywheel weight; it had none of the attributes of a heavy flywheel.

At $294.99, the CNC-machined steel Hinson basket costs $30 more than the high-tech Akadized aluminum basket.

There you have it. The choice is yours and you control your fate with your left hand. Use it with caution.

Comments are closed.