HOT BIKES AND HOT TEMPS!

Horsepower is heat. The spark plug fires 200 times per second. The piston approaches sonic speeds. The exhaust pipe hovers at the melting point of steel. The radiator water could poach an egg. The more power that a modern two-stroke engine makes the hotter it runs. Paradoxically, even though horsepower is heat, the cooler the engine the more power it will make. How can that be? It’s simple. Metals have melting, fatigue and expansion points that eventually bring the escalation of ponies to a screeching halt. It is possible to produce a 40-horsepower 125, but more than likely it would be prone to blown head gaskets, seized pistons, warped heads, bearing failures, detonation and overheating. To build a hot engine-you have to keep it cool. The more efficient the engine’s cooling system, the more heat (as in horsepower) it can handle.

A HARD LESSON LEARNED

At the start of the ’98 AMA National season, most factory teams gave lip service only to engine cooling. Honda, Yamaha, Kawasaki and Suzuki were engaged in a horsepower war-and that was all that mattered to them. But, as the dyno numbers grew, the engineers began to discover that the engines couldn’t handle the heat. This became most evident in the wet sand of Southwick, where the high loads stressed the engines beyond the breaking point (especially in the 125 class). From Southwick on, every factory’s R&D team began working day and night on cooling down their engines.

How hot does an engine run? The hottest spot on your bike’s engine is the head pipe. It runs at 1200 degrees (with hot spots that verge on the 1300-degree melting point of mild steel). The rest of the pipe warms to 600 degrees (so don’t touch it). Cylinder temperatures are also in the 600-degree range, while the water temperature should vary from 200 to 300 degrees (the closer to 300 the closer to catastrophe). Most race teams would like to keep their basic water temp below 200 degrees if possible.

“Cooling” has become the buzz word of ’98-and you can expect it to play a big part in the future of motocross bike design. Here is a look at what the teams are doing to fight the war on heat.

RADIATORS: BIKES ARE STILL AIR COOLED

A motocross radiator is designed to turn 300-degree water into 180-degree water. It does this by air cooling it. Many teams run different radiators on their race bikes to help air cool the water. Honda uses a CR250 radiator on Steve Lamson’s CR125 (not for more fluid volume, but because it has better coolant vanes). Jeremy McGrath and Kevin Windham have larger capacity radiators on their YZ’s.

WATER: WHAT GOES IN MUST COME OUT

What you put in your radiator makes a difference. The average local racer runs a 50/50 mix of water and antifreeze. This aids in preserving the radiator’s life and raising the boiling temperature of water above 212 degrees. Race teams run a 75/25 mixture, but they add Red Line WaterWetter to improve the temperature absorption of the liquid.

Teams also experiment with different radiator caps to pressurize the water in the system. Caps come in all different ratings and these can be used to raise the boiling point.

WATER PUMP: JULES VERNE & EYVIND BOYESEN

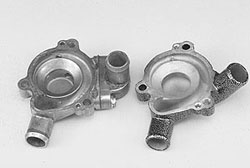

When Boyesen Engineering released its high-flow water pump cover last year, many people questioned the need for a more efficient water pump cover. Not any more! Boyesen’s cover increases water flow, lessens cavitation (air bubbles in the water), reroutes the outlet (away from the heat of the pipe) and lowers engine temps a measurable amount. Why is this so important? Because the hottest water in the engine is located on the inlet side of the water pump.

Boyesen’s water pump cover is not available for every model of bike, so Team Honda, after analyzing its water pump, filled the water pump with a Bondo-like substance and reshaped the internals to mimic Boyesen’s nautilus shell design. Honda claims that the efficiency difference is significant.

RADIATOR WINGS: CATCHING AS MUCH WIND AS POSSIBLE

Have you seen the ’99 Suzukis? They have barn doors attached to their radiators-or at least that is what their new jumbo-tron radiator wings look like. Not only are the Suzuki radiator wings larger in surface area, but they are also fanned out farther than in ’98. The goal? To catch the wind.

Team SplitFire has been testing rivet-on extensions to their KX125 radiators wings, while Team Honda and Team Honda of Troy have built rudder-like wings on the tops of their radiator wings to draw more air directly through the large single radiator of the CRs. Apparently, Honda’s engineers believe that one large radiator is not as efficient as two separate radiators-even though one radiator has more surface area and a larger fluid capacity. It is thought that a large portion of the single radiator is blocked by the front fender, fork legs and triple clamp, while the frame and engine impede air flow from the back side. Stefan Everts’ works CR250 uses twin radiators on the 250 GP circuit.

Some teams have even resorted to drilling hundreds of small holes in the Venetian blind radiator guards to get more air into the radiators.

FRONT NUMBER PLATES: AIR FOILS AND THE DRAFT

Team SplitFire took their bikes to a race car aerodynamacist to have them analyzed. The first thing he told them was to get rid of the front number plate. The car designer said that the broad curved shape of the front number plate created an air foil that decreased the amount of air going into the radiators by 30 percent (much like the windshield on a convertible creates a back draft that blows your hair forward instead of backward). Pro Circuit/SplitFire team manager Mitch Payton had a wire mesh front number plate designed the next day.

What else did the aerodynamics expert say? Shockingly, he said that with the rider on the bike, the exit vents on the radiators are inefficient. Even if you scoop more air into the radiator wings, it will not cool the engine one iota more if it can’t escape. To get more air in, you have to draw more air out. The car guy recommended air scoops, tubes and vents-all of which are used on race cars and road racers-but will not fit on a motocross bike. Team SplitFire is looking at enlarging the exit vents on its radiator wings.

IMPELLERS: TO THE MELTING POINT

One way to cool an engine is to flush the water through it faster. So, why don’t the factories just increase the water pump impeller speed (measured in gallons per minute-gpm)? Because if you pump water faster than the radiators can cool it, you will be circulating hot water instead of cool water. The complete system is very sensitive to temperature (including the ambient air temperature).

To make the most power, you have to have the coolest engine possible. Boyesen Engineering, which has done considerable heat testing, says that they have never seen an engine run too cool. Theoretically, the colder the engine the better (because it will be able to accept more heat from the combustion and friction process).

What about cold seizure? Cold seizing was a problem in the early ’80s on Suzuki RM125s. If early water-cooled RMs were not warmed up properly, the piston would seize because of the heat differential between the expansion of the piston and cylinder liner. Thanks to improvements in piston design and new cylinder linings, though, this is no longer a problem-unless engineers bring engine temperatures down dramatically.

WHAT DOES IT ALL MEAN?

In the high stakes world of professional motocross, controlling the temperature means the difference between a successful season and a disaster. Team Honda first noticed their heat problem at some outdoor test sessions (the problem is less significant in supercross because of the lower ambient temperatures and shorter races). For the first ten or 15 minutes of a test Steve Lamson’s bike ran great, but near the 20 minute mark it began to lose power. As the engine got hotter, the integrated system of bearings, tolerances and friction surfaces began to run afoul of each other. Honda knew that it had to find a way to keep the engine cool longer. By changing radiators, adding winglets above the radiator, Bondo’ing the water pump and using WaterWetter, Honda was able to bring the temperature down from 208 degrees to 192 degrees.

Team SplitFire paid the ultimate heat price at the Southwick 125 National when Ricky Carmichael’s KX125 got so hot that it blew the head gasket-causing him to DNF. Amazingly, Carmichael’s bike had been detuned for the power robbing sand and a special low compression head had been fitted that day to avoid the problem. But, the heat got him anyway.

Heat may not rob the local racer of a National Championship. And in many cases local motos are too short to steal that much power from the engine. However, heat wears an engine out. It causes rapid expansion and retraction of the parts, prematurely fatigues metal and, in the long run, could cost you big bucks in repair bills.

A cooler engine lasts longer-and goes faster to boot.

Comments are closed.