JOHNNY JUMP ON ODI GRIPS’ HISTORY, STRUGGLES & OPPORTUNITIES

Johnny Jump is the powersports sales and marketing manager for ODI Grips.

Johnny Jump is the powersports sales and marketing manager for ODI Grips.

BY JOSH MOSIMAN

ODI Grips has deep roots in the motocross and bicycling industries with ties to Jeremy McGrath’s custom-painted helmets, Troy Lee Design’s custom visors and John Tomac’s signature mountain bike grips. Just as a rising tide lifts all boats, the increased demand for motorcycles and mountain bike products has boosted sales for ODI this past 18 months; but, if it weren’t for a few key decisions, ODI might not be doing as well. MXA sat down with ODI Grips’ powersports sales and marketing manager Johnny Jump to explain the history behind the ODI brand, expound on how owner Dave Grimes started his injection-molding business, describe how ODI was able to create innovative products and shed light on what he thinks are the biggest challenges facing the future of the action sports industry.

Jeff Emig’s ODI Emig grip helped the company reach the next level.

Jeff Emig’s ODI Emig grip helped the company reach the next level.

HOW DID ODI GRIPS START? ODI started back in the ’70s. The company was originally making skateboard parts, boogie board parts and some random things like Christmas ornaments. Its first major hit was the mushroom grip in the 1980s when BMX was booming. The original owners were a German couple, Herb and Kay, and Herb made his own tooling. They ended up selling ODI in the mid-to-late 1980s and planned on retiring. Then, the new owners didn’t fulfill their part of the contract, and Herb and Kay ended up starting another grip company called ATI. The two companies competed back and forth and, at one point, Dave Grimes, the current ODI owner, became a molder for ODI with his Edge Plastics company, making grips for them. After ODI went through a series of owners, the final owners got themselves into financial difficulty in 1992 and approached Dave about buying the company.

“ODI STARTED BACK IN THE ’70s. THE COMPANY WAS ORIGINALLY MAKING SKATEBOARD PARTS, BOOGIE BOARD PARTS AND SOME RANDOM THINGS LIKE CHRISTMAS ORNAMENTS. ITS FIRST MAJOR HIT WAS THE MUSHROOM GRIP IN THE 1980s WHEN BMX WAS BOOMING.”

WHAT WAS DAVE DOING BEFORE HE BOUGHT ODI? Dave didn’t have a sports background; he came from an injection-molding background. He worked his way up to become the general foreman of an injection-molding shop, but that company went bankrupt, and since Dave knew all of the jobs and customers, he bought two of their best machines at the auction. He went to the biggest customers and said, “Hey, I’ve been molding your parts for the last 10 years. Give me a shot.” He mortgaged his house and pulled himself up by his bootstraps to create Edge Plastics.

ODI still has the original mushroom grips that launched the brand into the BMX world and the original motocross grips that competed with Oakley and AME back in the day.

ODI still has the original mushroom grips that launched the brand into the BMX world and the original motocross grips that competed with Oakley and AME back in the day.

WHERE DID ODI GO FROM THERE? Dave bought ODI and all of its assets and didn’t acquire the debt. But, he paid all of the athletes and all of the past royalties to get everything right for the brand. From there, Dave started reinventing the company. Four or five years later, ODI launched the first lock-on grips in the mountain bike market.

ODI makes the lock-on grips for KTM, Husky and GasGas models.

ODI makes the lock-on grips for KTM, Husky and GasGas models.

EDGE PLASTICS WAS MAKING PRODUCTS FOR TROY LEE, TOO, RIGHT? Dave’s shop was located in Corona, California, in a little strip mall right next to the Troy Lee Designs building. He was making some of the Troy Lee visors and accessories. Dave and Troy got together to make the original Aero visor. It wasn’t a helmet visor; it was literally just a sun visor you’d wear at the beach. They were popular at the watercraft races, and Troy Lee Designs painted them; however, when you painted the standard material, the different solvents and paints would make them super brittle, and they’d crack and fall apart. That same issue came up with Troy’s motocross visors as well. It took a lot of testing to figure out the materials. Dave made a lot of hard parts for Troy Lee, including visors, mouth pieces, and even the wings on the back of Jeremy McGrath’s helmets.

WHAT WAS THE GRIP MARKET LIKE IN THE EARLY DAYS FOR ODI? Dave was really trying to innovate new ideas. Right about that time the idea of having two different densities in a grip was brand new. ODI was only making grips at the time, and the top seller was the Tomac Attack grip. The previous ODI owner had not paid the royalties owed to John Tomac, so they lost the rights to use the name Tomac, and it got rebranded as just the Attack grip. Dave caught John Tomac up on all of the royalty payments but still didn’t have the licensing for the name, so they just built off of the Attack grips. At one point Dave was making all of the OE grips for Trek when its bicycles were still being made in Waterloo, Wisconsin.

“ORIGINALLY, IT WAS ‘ORNATE DESIGNS INCORPORATED.’ BUT, THAT DIDN’T FIT OUR COMPANY IDENTITY. WE WENT THROUGH A PROCESS OF REDEFINING, AND CAME UP WITH ‘OBSERVE, DESIGN, INNOVATE.’ IT FITS OUR MANTRA”

The Rocky Mountain KTM team uses ODI handlebars and grips.

The Rocky Mountain KTM team uses ODI handlebars and grips.

WHEN DID THE FIRST MOTOCROSS GRIP COME FROM ODI? We have some grips here from when Herb and Kay owned the company that have Rick Johnson as an Amateur on the packaging from the ’70s. BMX and motocross kind of grew up together and diverged. When the mushroom grip hit, Herb and Kay went more towards the bike side and didn’t push as hard for motocross; however, the whole time ODI had been making private-label motocross grips for other companies. There are some other very recognizable brands whose grips we’ve made for many, many years. In the early 2000s, we relaunched the ODI-branded motocross grips.

WHAT DOES THE ACRONYM ODI STAND FOR? Originally, “Ornate Designs Incorporated.” But, that didn’t fit our company identity. We went through a process of redefining, and we came up with “Observe, Design, Innovate.” It really fits our mantra. We observe and gather information from top Pros. We watch what they’re doing. We look at wear patterns. We look at many different points of data and then bring it in-house. Having the tooling, the production and packaging in-house allows us to innovate at every level of design. This goes for our grips as well as our handlebars and other products.

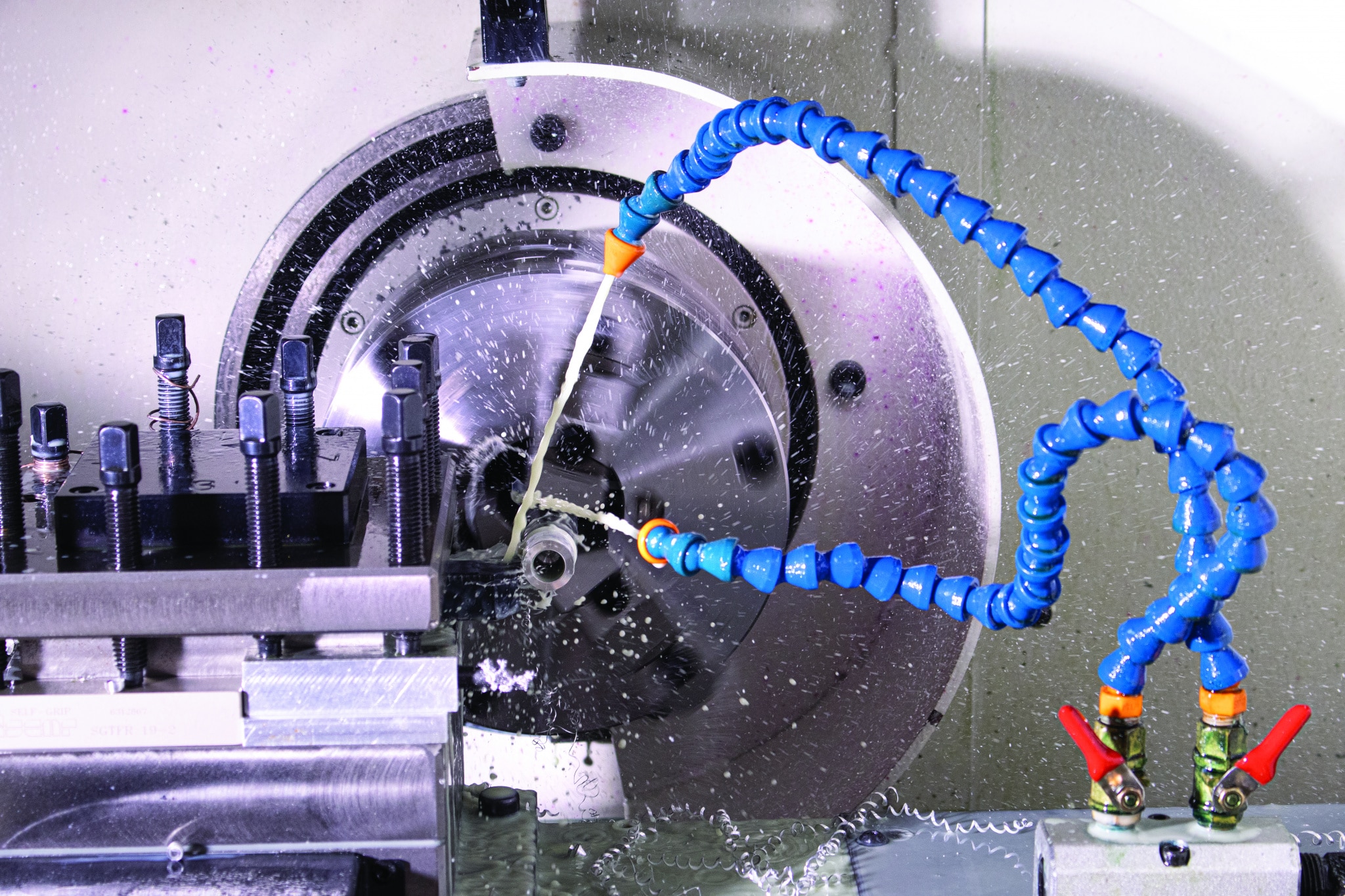

The ODI production facility in California produces products for powersports and cycling alongside its parent company, Edge Plastics, which makes pool, dental, medical and aircraft supplies.

The ODI production facility in California produces products for powersports and cycling alongside its parent company, Edge Plastics, which makes pool, dental, medical and aircraft supplies.

HAVING THE PRODUCTION IN-HOUSE MUST HELP WITH DESIGNING NEW PRODUCTS, TOO. We annoy our tooling department with wild ideas. We tell them our idea and they say‚ “Well, that’s really hard to do.” And we say, “Exactly.” The rubber durometers, the material, the mold sizing, the shape, the diameter, the blends and everything has to come together to get that final intent. For example, we spent 2-1/2 hours with Jeff Emig debating over half a millimeter on one particular portion of the Emig Pro grip. Originally, our Control Flex Technology (CFT) handlebar was built for motocross and Supercross. Now, Cody Webb and the Sherco off-road team are using it in hard enduro. They think it’s amazing because it’s got the vibration damping they need for hitting rocks, roots and ruts.

WHO ARE SOME KEY RIDERS WHO HAVE HELPED YOU DEVELOP PRODUCTS? The Star Racing Yamaha team helped us quite a bit with the lock-on system for racing Supercross and motocross. They were the first team that adopted it, proving it does work in this environment, day in and day out. We won three Championships with them. Blake Baggett helped, too, when he was with Rocky Mountain KTM. He is a very, very particular rider. He helped us to understand the needs of a finicky rider at that level of competition. He helped us with our materials and how the throttle sleeve needed to work to suit the wrist and hand issue he had. He was very sensitive, and we’ve developed some parts that we’re still working on from some of his feedback—and I think it’s going to be pretty enlightening once we release it.

Alex Martin put together his own program with the Manluk/Rock River/Merge Racing Yamaha team last season, and he used ODI grips and handlebars.

Alex Martin put together his own program with the Manluk/Rock River/Merge Racing Yamaha team last season, and he used ODI grips and handlebars.

TECHNOLOGY FOR GRIPS TRANSFER BETWEEN MOTOCROSS AND MOUNTAIN BIKING? The technology feeds off each other. The raised center on the Emig Pro grip came from our Elite Pro Mountain bike grip, which was developed with Specialized rider Curtis Keene. The aluminum end cap on our lock-on motocross grips came from our Aaron Gwin mountain bike grip. The original single-clamp lock-on system that we started with in motocross in 2001 went from motocross to the mountain bike system shortly after. At the time, we were using all dual-clamp systems in the bicycle world because mountain bikers were nervous about the single clamp until they realized motocrossers were using it.

YOU MAKE A LOT OF STUFF IN CALIFORNIA, BUT HANDLEBARS COME FROM OVERSEAS, RIGHT? We make as much as we can in Riverside, California. When we started looking to make handlebars, it was really difficult to get the materials that we needed in the USA, and it wasn’t cost-effective for the end user. We ended up having to go overseas, but we didn’t just walk into a trade show and say, “Hey, put our name on this.” We started from scratch. We did our research. We learned everything that we could. For example, there were Pro racers who would cut their crossbar in half and stick the foam pad over it, just to increase flex. That sparked the motivation for the “Control Flex Technology” (CFT) bar. We feel like our CFT bar is significantly different from what anybody else in the market has and helps limit vibration to boost comfort and performance.

Justin Bogle’s ODI-equipped KTM 450SXF.

Justin Bogle’s ODI-equipped KTM 450SXF.

HOW DID ODI SURVIVE THE COVID-19 LOCKDOWNS AND RESTRICTIONS? When the COVID-19 shutdown happened, we originally intended to pull back to half the employees on a four-day work week so we would have more spacing. We anticipated a slowdown. I remembered 9/11, and when that happened, the phone just stopped ringing the next day. It was like someone had turned off the spigot. A couple of days into cutting ODI’s workforce back, we called everybody back in because the powersports market kicked in first and really started showing that people were still out riding. Shortly thereafter, the bicycle market woke up. I would relate it to when you’re wakeboarding. The boat turns really sharp and you get slack in the rope, there is moment’s pause, and then when it hits, it hits. That’s exactly what it hit like for ODI and our industry.

HOW IS ODI DOING NOW? We have the same supply shortages and delays on shipments like every other company in America. We are really lucky to have worked with some of our material suppliers for over 30 years. We have a lot of exclusive and proprietary blends with these guys, and they bent over backwards to really help us out. We actually pulled the trigger on additional equipment in April of last year, anticipating sales growth. If we didn’t have that equipment now, we would be much further behind. By the end of this year, we should have another 30 percent of capacity added on the grip side. It’s been a roller coaster. A lot of jobs have changed. We went from building to stock to building to order. We’ve gone from trying to make sales to just managing everything that’s coming in.

ARE YOU OUT OF STOCK ON MANY PRODUCTS? Out-of-stock situations are our reality nowadays. We run our production facility 24 hours a day, five days a week. We have been trying to pick up weekend shifts, but we can’t get enough of the key people, like the foreman and the material handlers, to be able to justify that. With the pandemic, we made a choice not to add any additional stress on our employees by trying to get them to work overtime on the weekends. If we’re going to work weekends, we’re going to bring a whole new shift in. The demand has increased enough that we can’t fulfill all the orders, so we’ve put stopgaps in place to try to slow things down. We’ve cut back on the number of colors that we’re offering. We’ve pulled back on web sales. We’re working with our tool room to increase capacity, and we’ve been adding equipment, but there’s no way that we can stay up at 100 percent on this stuff.

“A COUPLE OF DAYS INTO CUTTING ODI’S WORKFORCE BACK, WE CALLED EVERYBODY BACK IN BECAUSE THE POWERSPORTS MARKET KICKED IN FIRSTAND REALLY STARTED SHOWING THAT PEOPLE WERE STILL OUT RIDING. SHORTLY THEREAFTER, THE BICYCLE MARKET WOKE UP”

WHAT DOES THE FUTURE LOOK LIKE? We’re really excited for both the powersports and bicycle industries. The adoption rate on this, I think it’s going to reverberate for years. It’s exciting to see so many newcomers to both markets and seeing that people are really choosing to go outside. I think our biggest area of concern right now is competition for growth from video games and complacency. Our enemy is kids staying inside and not going outside to do real things. It took a pandemic to get them off their butts and outside riding.

ODI is able to create innovative products with its in-house tooling engineers at the Riverside, California, facility.

ODI is able to create innovative products with its in-house tooling engineers at the Riverside, California, facility.

THERE’S STILL ROOM TO GROW, TOO, RIGHT? Yes. We have some new developments that we can get back to. We’ve had some other opportunities to build products for more potential OEM and private-label customers that we put on hold as well. I’m hoping with all of the new consumers who have been out buying bikes or refurbishing old ones that we’ve planted some new seeds. We aren’t the only grip and handlebar manufacturer in the marketplace, and every aftermarket supplier has been having trouble delivering. If a consumer switched to ODI because they couldn’t get their previous preferred brand, we’ve planted that seed, and hopefully they’ve had a good experience with the brand.

Comments are closed.