TEN THINGS ABOUT AFTERMARKET MOTOR MOUNTS & HEAD STAYS

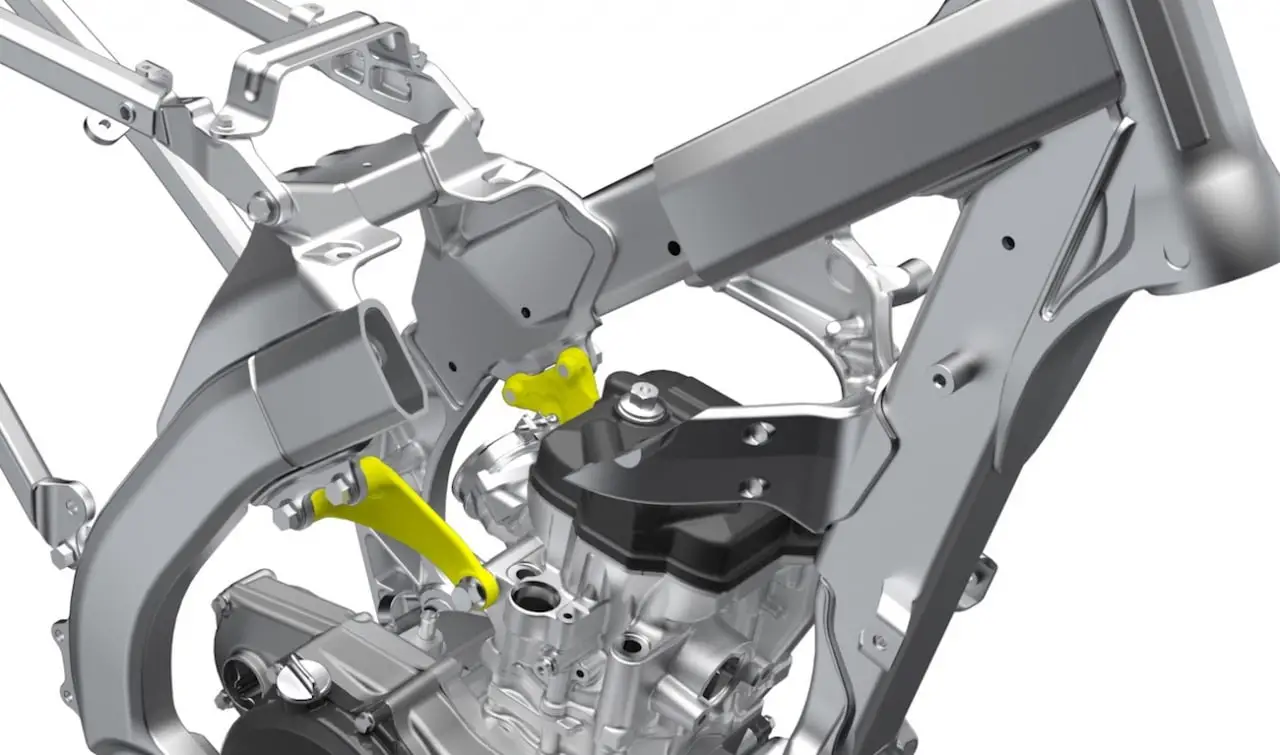

Small tweaks on a head stay make a difference. This is a CAD drawing of an FCP mount.

Small tweaks on a head stay make a difference. This is a CAD drawing of an FCP mount.

(1) Handling. A fast motorcycle is futile if you can’t hang on to it. The engine, frame, suspension and triple clamps work in combination with the rest of the bike to determine its handling characteristics. The optimal setting for you to have fun on or go fast with is found when your bike is balanced, you feel at home on it, and you can predict how it will react in all the situations you might face on the track.

(2) Factory access. There are many ways you can custom-tailor a bike to suit your size, speed and style. In the past, only factory teams had access to custom motor mounts and head stays, but now companies like FCP (Factory Chassis Parts) are selling aftermarket mounts to the public.

(3) Stiff vs. soft. In general, stiff suspension and/or a rigid frame contributes to a quick, sharp and precise-handling motorcycle. Stiff means the rider will feel more feedback being passed through the handlebars and the response of the chassis isn’t muted by flex. Conversely, softer suspension and a flexible frame create a more comfortable feeling on the track that generally isn’t as quick to react or as precise, but is more forgiving. A skilled rider can easily tell the difference between stiffer and softer motor mounts, and more specifically head stays.

(4) Motor mounts. Motor mounts are the ligaments that connect the motorcycle’s engine to its frame, causing the engine to become a partially stressed member of the chassis it’s bolted to. Engines are heavy. They produce big torque and horsepower numbers that generate considerable gyro effect. It’s the frame’s job to hold the engine in place, while also soaking up energy that travels through the suspension. These forces cause the frame to flex. Motor mounts affect the chassis by allowing the engine to flex more or less inside the frame, increasing or decreasing the bike’s rigidity.

(5) Front motor mounts. All motocross bikes have front and bottom motor mounts that connect the engine directly to the frame in conjunction with the swingarm pivot bolt. FCP uses titanium for its front motor mounts and a special titanium bolt. Titanium can boost front-tire traction and accuracy on corner entry because of titanium’s modulus of elasticity.

(6) Head stays. Head stays get more publicity because they’re easier to spot. They connect the engine to the frame via a bracket between the cylinder and frame. Generally, head stays affect the motorcycle the most when the rear end of the bike is being loaded. This happens any time you’re on the throttle; for example, in the middle of a corner, through its exit, and accelerating down a straight. Typically, aftermarket head stays work to increase flex over bumps.

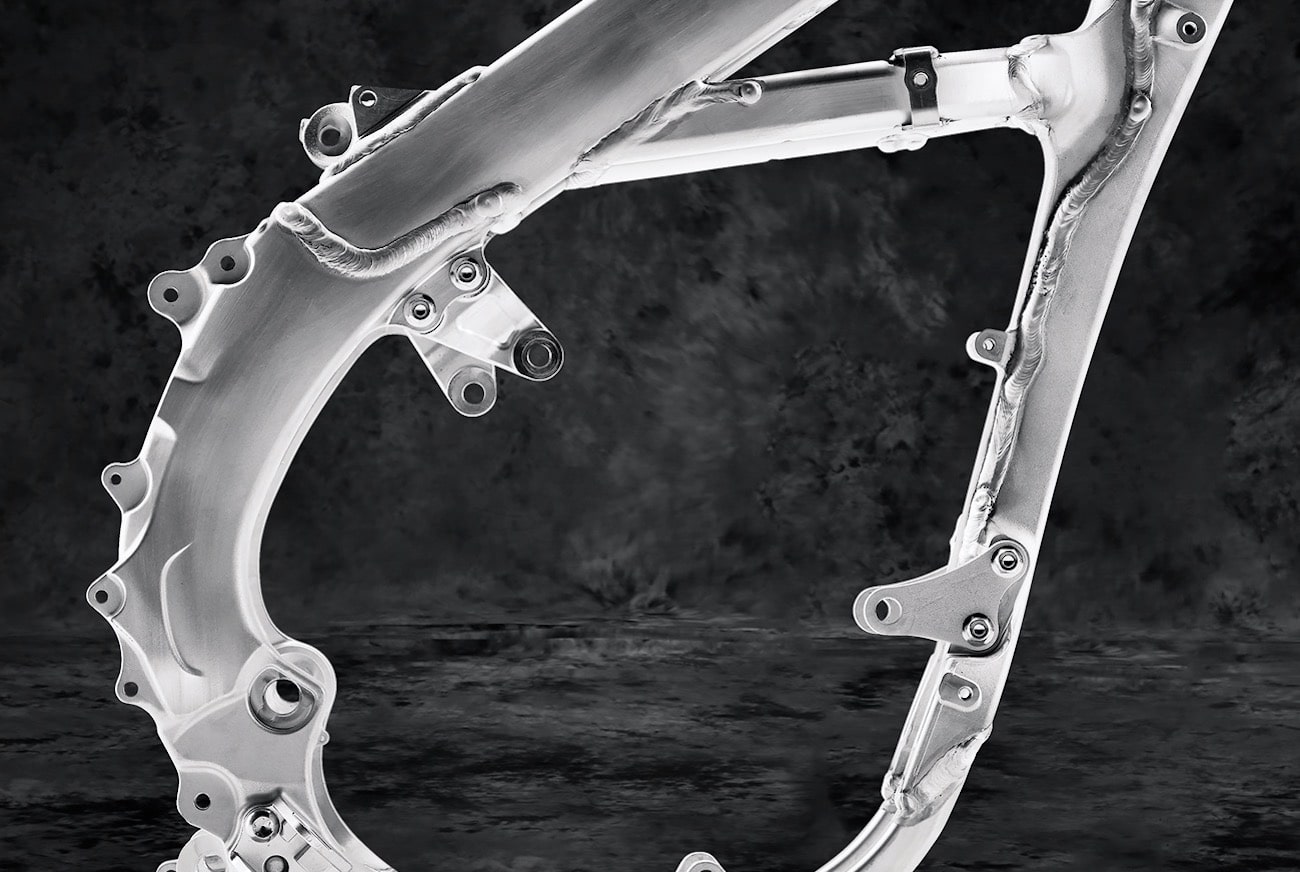

Yamaha has a history of chasing chassis stiffness and flex by redesigning their head stays and motor mounts.

Yamaha has a history of chasing chassis stiffness and flex by redesigning their head stays and motor mounts.

(7) Yamaha. Manufacturers redesign their motor mounts, along with their head stays, at regular intervals. The YZ450F is a prime example. In 2014 previous aluminum lower motor mounts were replaced by steel plates. In 2016 Yamaha made the head stays stiffer, by making them thicker. In 2018 they changed to aluminum head stays, reshaped them and moved them lower on the cylinder. For 2020 the YZ450F’s previous 8mm-thick, steel motor mounts were replaced by 8mm-thick aluminum motor mounts, while the head stays went from 9.5mm aluminum plates to 6mm steel plates.

(8) KTM. In 2019 KTM introduced a new frame with redesigned head tube gusseting and a larger cross brace that made the frame 10 percent stiffer torsionally (side to side) and just slightly stiffer longitudinally (front to back). The stiffer, more rigid chassis was liked by Pros for its improved accuracy but disliked by Vets and Novices because of its harsher chassis feel. Since 2019 KTM has improved its suspension, especially the WP XACT air forks, to work in coordination with the stiffer frame, but some riders prefer aftermarket motor mounts on their 2019–2022 KTMs because they make the new frame feel more like the forgiving 2018 chassis. Even factory teams like Red Bull KTM and Rocky Mountain KTM have been seen at the races using FCP engine mounts.

Here’s Joey Savatgy’s Rocky Mountain KTM 450SXF with the FCP motor mount.

Here’s Joey Savatgy’s Rocky Mountain KTM 450SXF with the FCP motor mount.

(9) Material. The material, thickness and hole size play a factor in a head stay’s performance. FCP Racing’s motor mounts and head stays use aircraft-grade billet aluminum or titanium for all of their parts. Each mount begins as a billet of 6061-T6, 7075-T6 aluminum or Grade 5 titanium. Then, the billet spends a significant amount of time in the CNC machine to receive its form and design.

(10) Torque specs. Before you invest a couple hundred dollars into aftermarket motor mounts, play with the torque settings on your stock motor-mount bolts. The recommended torque number represents how tight your bolts are, and, conversely, the tighter they are, the less flexibility your mounts will have. Look up the recommended settings and then try going tighter and looser (within 10 percent of that number) to see if you can feel any benefit. If you still aren’t happy, try aftermarket engine mounts as your next step.

Comments are closed.