FORK WORKS: THE LIFE & DEATH OF AIR FORKS

Now that the air-fork craze has subsided to a whisper, with only the 2018 Kawasaki KX450F still running the full-blown Showa TAC air forks that were de rigueur over the last five years, it’s time to look back on why Showa and Kayaba air forks failed so spectacularly, why this was the second time air forks failed and why KTM came out of the air-fork debacle on the sharp end of the stick.

Air forks are nothing new in motocross, as the 1976 Yamaha’s 35mm Kayaba air forks prove. The most visually unique aspect of the 41-year-old air forks was the air accumulators that replaced the fork caps. The two air canisters resembled the instrument cluster of a street bike, leading to the Kayaba air forks being called “speedo & tach” forks.

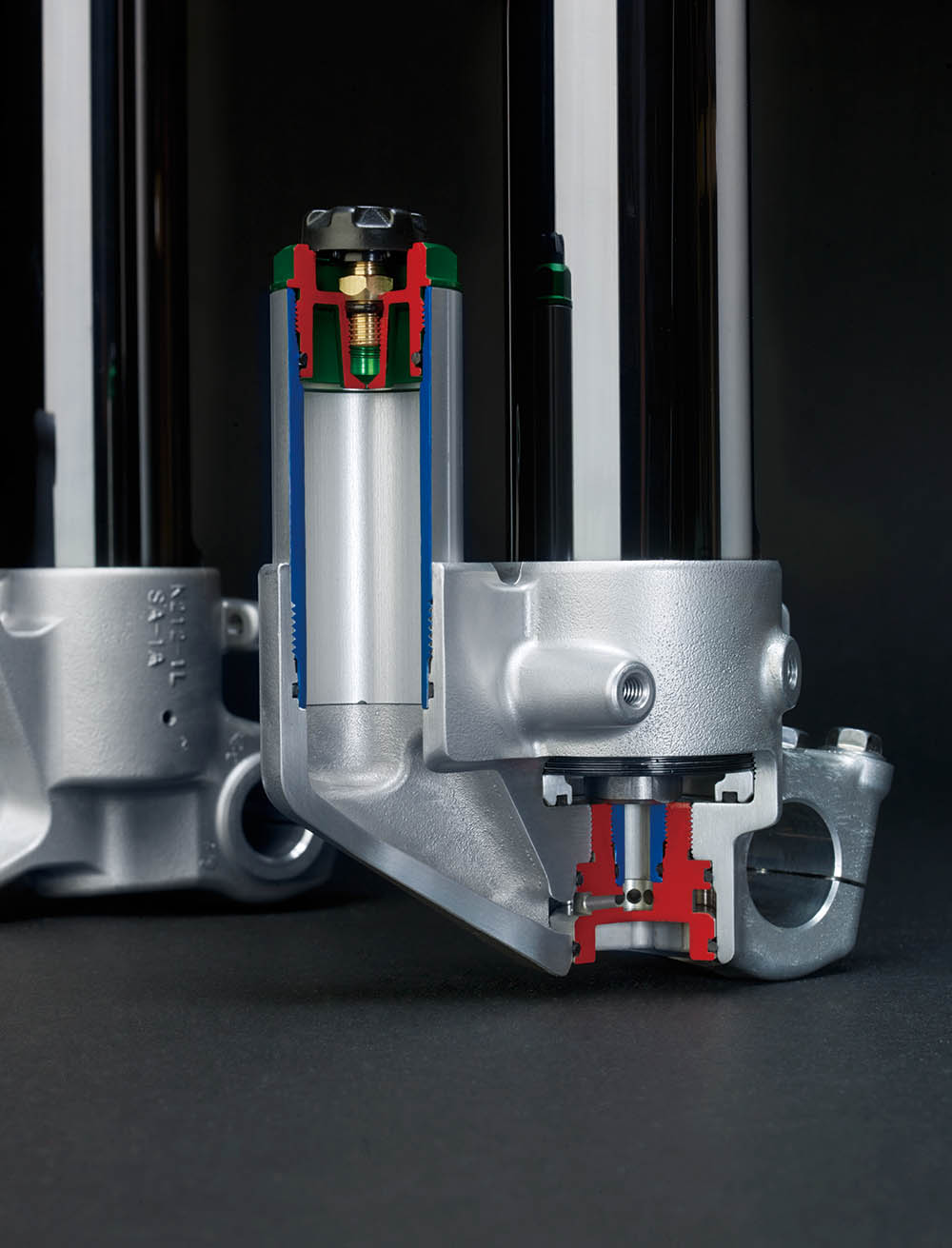

The design of the accumulators was incredibly inventive. The canisters were empty, save for a floating piston and two Schrader valves on each canister (one below a floating piston and one above it). The piston separated the canisters into two separate air-pressure chambers, which allowed the air pressure to have a dual rate. The trick was to put just enough air pressure in the lower air valve to hold the forks at the proper ride height (they would stiffen as the air was compressed by upward movement). The upper Schrader valve fed the high-pressure side (above the floating piston), and, as the fork moved through its stroke, the air pressure in the lower chamber pushed the floating piston upwards against the higher pressure inside the canister. The goal was to have plush forks for small to mid-sized bumps via the lower air pressure and a more linear and stiffer air pressure as the floating piston was pushed upwards. Back in 1976, MXA ran 27 psi in the low-pressure side and 50 psi in the high-pressure side.

By allowing adjustment of the air pressure in the low and high air chambers, the forks offered a very wide range of spring rates. The forks could be tuned with oil-height changes to determine when the cross-over effect of the floating piston would kick in.

While the 1976 Kayaba air fork was innovative, the forks were doomed to failure because their valving was atrocious and, as riders soon found out, they topped out on the rebound stroke. They clanked on the way back to full extension. But even though the 1976 Yamaha air forks never saw a second year of production, local riders would take the coil springs out of their front forks, drill a hole in their fork caps and thread Schrader valves into the holes. Voila—inexpensive air forks! But, the air-fork craze only lasted from 1976 to 1977 and then died.

All was quiet on the air-suspension front until 2013 when both Kawasaki and Honda made Kayaba PSF air forks OEM equipment on the CRF450 and KX450F. They were soon followed by Showa SFF TAC air forks. The air show was on again. This time it lasted for four years before it, too, died, leaving only the WP AER air fork standing.

So why has the WP AER fork succeeded where Showa and Kayaba failed? That’s easy. WP kept its air fork simple. PSF and TAC air forks were too complicated for the average rider to adjust and too hard to keep in the sweet spot once properly adjusted. Consumers hated having to check multiple air valves every time they rode—and they revolted.

Why haven’t they revolted against the KTM and Husky air forks? Because the WP forks only have a single air valve. Basically, WP just replaced the coil springs with air pressure. They didn’t ask the air to do anything else, because the much-needed balance chamber was self-adjusting. It turns out that when it comes to Schrader valves, three is way too many, two is still too many but one is just right. Goldilocks would approve.

Comments are closed.