TEN THINGS ABOUT SUSPENSION SHIMS, SHIM STACKS & CLICKERS

Dear MXperts,

My understanding of how motocross suspension works doesn’t go much beyond turning clickers with a screwdriver and, even then, I don’t know what I’m actually changing. The inner works of the my forks or shock are a total mystery. to me. Can you give a grade school primer on how what’s going on when I adjust my suspension and more, importantly what happens when I send them out of a suspension shop?

At its most basic level your bike’s shock and forks utilizes springs to hold the fork and shock up in its stroke. The correct spring rate (or air pressure on WP forks) is determined by the combined weight of motorcycle and rider. Then, the suspension components use oil and shims to control its damping characteristics—stiffer shims or thick oil viscocosity for fast riders who hit bumps and jumps harder, or softer shims and light oil viscocity for slow riders who aren’t putting as much stress on the suspension and are looking for a plusher or more compliant ride.

Shims are nothing more than thin flexible steel washer, and they are your suspension guru’s main components for customizing the suspension settings. Shims are thin, round pieces of Sandvic steel that come in a variety of diameters and thicknesses and are used to restrict oil flow through the pistons in your suspension. The outer-dimension (OD) measurement for shims ranges all the way from 8mm to 45mm, and the thickness range is from 0.05mm to 0.3mm. Shims that are smaller and/or thicker make the suspension stiffer. The smaller shims have less leverage to bend them, which requires more force, and thicker shims are simply not as flexible. The opposite is true for bigger and thinner shims.

The outer-dimension (OD) measurement for shims ranges all the way from 8mm to 45mm, and the thickness range is from 0.05mm to 0.3mm. Shims that are smaller and/or thicker make the suspension stiffer. The smaller shims have less leverage to bend, which requires more force, and thicker shims are simply not as flexible. The opposite is true for bigger and thinner shims.

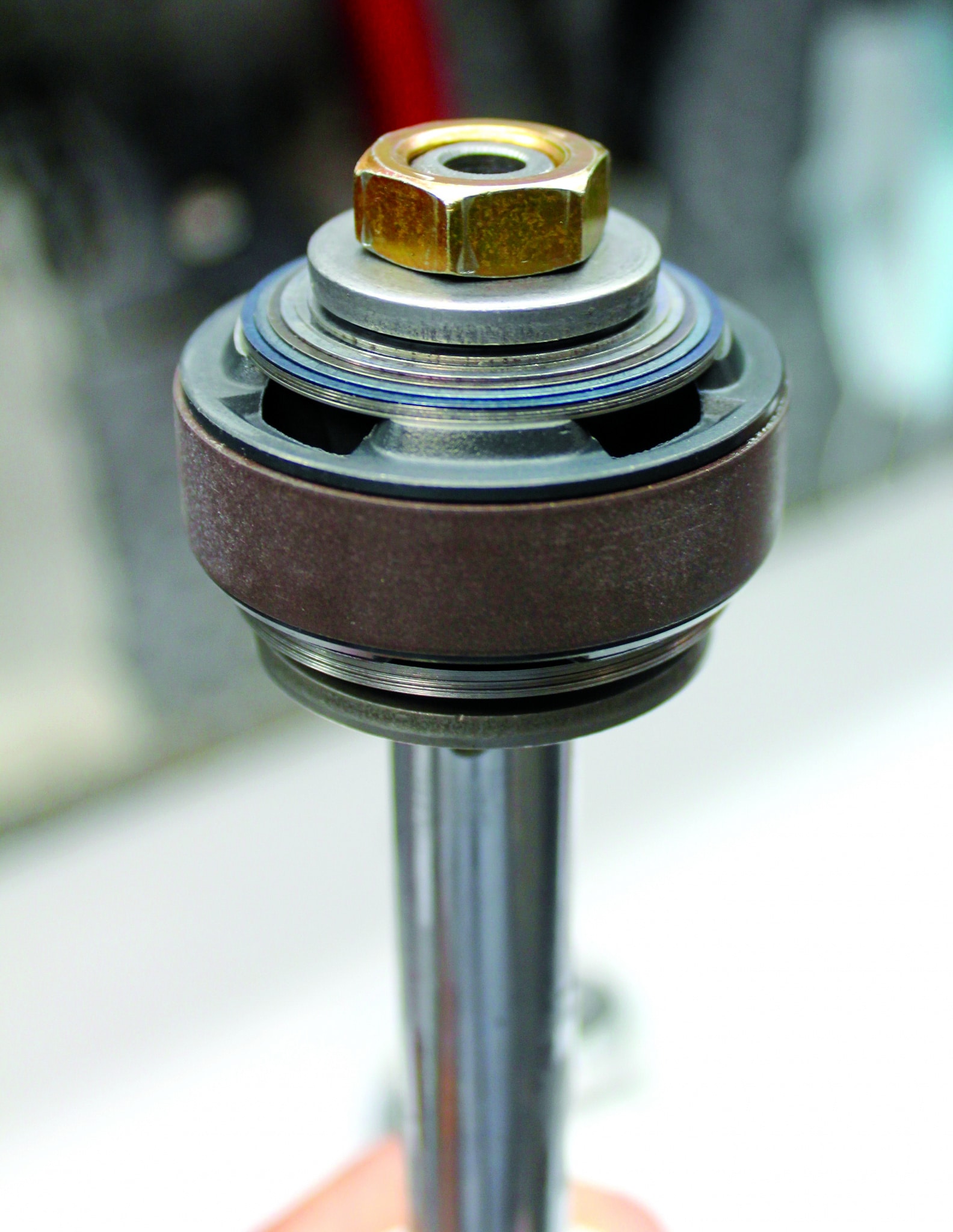

As the suspension compresses, oil is plunged through the cartridge, which contains the oil and shims, and is forced to go through ports in a piston. The thin discs of steel sit on top of the valve openings, and under force, they’re pushed open. The shims hinder the oil’s flow, which slows down the suspension’s speed as it travels through its stroke, creating a stiffer sensation for the rider. Shims are used for controlling both compression (going down) and rebound (extending back).

To create the damping, shims of different sizes and thicknesses are stacked together in a specific order. The first shim is the clamp shim; the initial bending point for all the shims. It’s followed by, on average, six face shims of the same size and thickness. Next is a smaller crossover shim that provides space for the face shims to bend under pressure. Finally, there is the actual shim stack, which from the side view resembles the shape of a Christmas tree. The big-to-small tree arrangement creates a softer feeling initially that gets stiffer as the suspension goes further down in the stroke to prevent you from bottoming out.

Before shim stacks were used, front fork suspension was damped by oil flowing through holes in a damper rod. Basically, the rod was tapered down to the holes near its end, and as the forks compressed, the oil was forced through the holes. To make the suspension soft, riders would either drill bigger holes or use an oil with a lighter viscosity rating that flowed easier. To make it stiffer, they would braze up the holes and drill smaller ones, or run heavier, thicker oil.

There are many ways to come up with a shim setting. One way of doing it is by imputing the shim sizes into a percentage ratio so you can determine the percentage that your suspension is getting stiffer or softer with each change. Using a 0.1 shim with another 0.1 shim doesn’t result in the same movement as a 0.2 shim. It’s much more complicated. The shim-setting percentage can be found by cubing the shim’s thickness and then multiplying it by 1000. This turns it into a whole number and makes it easier to determine the percentage ratio of a suspension setting. For example, 0.1 turns to 1, 0.15 turns to 3.4, and 0.2 turns to 8. With the shim numbers added together, a suspension technician can easily determine a percent ratio for making methodical changes.

Shim stacks in the shock are generally the same, but there are a few different variations, either single stage or two-stage. The single stage doesn’t have a crossover or separator shim between the face shims and the rest of the stack. The use of single-stage shim stack in the shock has gone out of style.

The externally adjustable compression clickers on your forks and shock don’t tighten or loosen shim stacks, but they do open and close bleed holes. This increases (opens) and decreases (closes) oil flow through the bleed holes to soften and stiffen the suspension. The compression clickers coordinate with the bleed holes in the compression assembly (or base valve), which is located at the top of the shock and fork.

The primary damping system for the compression and rebound on suspension is found in the main compression assembly (or mid-valve) in the shock and forks. This is where the majority of the damping work is done. The suspension’s rebound can be sped up or slowed down by opening or closing a bleed hole with the rebound adjuster at the bottom of the fork and shock components; however, the compression shims can only be adjusted by taking the suspension apart.

Comments are closed.