TEN THINGS ABOUT TRIPLE CLAMPS

(1) Concept. Dirt bikes are intricate machines made up of many moving parts, most of which affect how the bike performs on the track. Triple clamps act as the ligament between your front wheel and the rest of the bike. They take input from the front wheel, relay it to the rider and vice versa.

(2) Material. Some key differences between stock and aftermarket triple clamps are the material and processes used to make them. Forging is the most popular process used for stock clamps. Yamaha, Honda, Kawasaki, Suzuki and GasGas each use this process, while KTMs and Husqvarnas come stock with CNC-machined clamps. Aftermarket triple clamps are also CNC-machined. Most triple clamps are made from aluminum, but the strength of the available types of aluminum differs.

Unlike its KTM and Husqvarna brothers, the GasGas bikes comes with forged triple clamps just like the stock Japanese bikes.

Unlike its KTM and Husqvarna brothers, the GasGas bikes comes with forged triple clamps just like the stock Japanese bikes.

(3) Forged clamps. Although it’s expensive, forging is an efficient way to produce large quantities of parts. Because triple clamps don’t see a lot of changes from year to year on stock bikes, it’s simpler for the manufacturers to produce a large number of triple clamps and use them for successive model years. The forging process uses a hydraulic or mechanical press to compress a billet of warm aluminum into a mold of the desired shape. The forging process isn’t as customizable as CNC machining.

(4) CNC-machined. The term “CNC-machined” is a short-form version of “CNC-machined out of billet.” The term “billet” refers to the starting material, which is a solid block of aluminum. CNC stands for “Computer Numerical Control.” A CNC machine is a complex milling machine that uses computer programs to cut away at the block of aluminum, sculpting the final product at a high level of efficiency, accuracy and consistency that would be too time-consuming with a manual process.

(5) Comparison. In general, forged aluminum clamps feel more flexible on the track. They offer more flex and comfort on the front end, while CNC-machined clamps typically offer more feedback to the rider’s hands, at the same time enhancing corner accuracy.

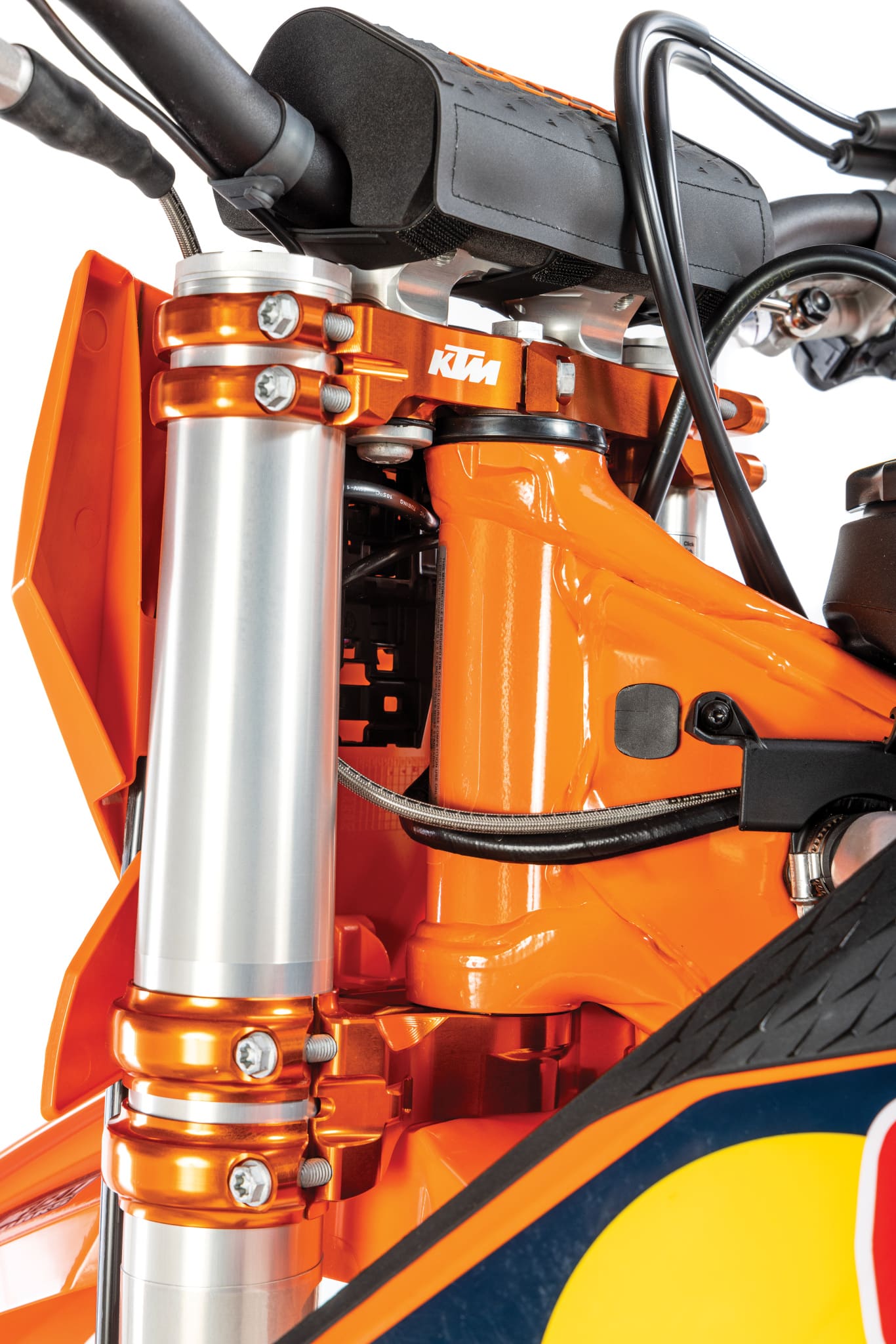

These split triple clamps are made by WP, and they come from the KTM PowerParts catalog.

These split triple clamps are made by WP, and they come from the KTM PowerParts catalog.

(6) Split clamps. The idea behind split clamps is to have a more even and secure connection to the forks. The main reason you want an even grip on the fork legs is to prevent the forks from binding. Like many other parts on your bike, your forks flex more than you think. When your fork flexes or twists, it kinks at the bottom triple clamp, which can squeeze the tubes and cause the inner fork-tube bushings to bind up, creating a harsh feeling on the front end. The separate clamping of split clamps flexes independently, smoothing out the kinks. This doesn’t completely stop the fork from kinking, but it helps. There’s not much bending going on at the top of the forks, so split clamps at the top have little effect.

(7) Torque specs. Like split clamps, how tight your 10mm bolts are can affect the handling of the front end as well. Too much torque on the bolts will cause your fork tubes to compress and bind up the bushings as they move up and down. All triple clamps have recommended torque settings, and the top bolts require more torque for safety to ensure the forks don’t slip. Going tighter on the top triple clamp doesn’t cause any binding, as the bushing doesn’t slide through that area.

(8) Bar mounts. The top triple clamps hold the bar mounts, which take a lot of abuse in a crash. There are multiple options, including solidly mounted and rubber-mounted. Some mounts offer two bar positions, and some clamps (i.e., Yamaha/Kawasaki) have two separate positions in their top clamps where you can mount the bars. With two separate holes and the ability to adjust the reach by rotating the mounts, there are four bar positions available on these bikes.

(9) Offset. The steering-head angle is the angle of the steering axis in relationship to the ground, and it’s determined by the geometry of the frame. Offset describes how far the front axle is “offset” from the steering axis. As a rule of thumb, less offset brings the front wheel closer to the chassis, reducing the trail and placing more weight on the front end, enhancing the bike’s ability to turn sharper. Increasing offset rakes out the front end more (think chopper) and increases stability.

(10) Offset testing. Bikes that are twitchy at speed (think Honda CRF450) benefit from the increased offset. Before changing the clamps, you should slide the forks down in the clamps to rake out the front end and increase stability. Once you determine if that helped with your stability problems, you can swap the stock 22mm-offset Honda triple clamps for 23.5mm-offset Ride Engineering clamps and love it—bingo!

Comments are closed.