TEN THINGS YOU NEED TO KNOW ABOUT CAMSHAFTS

(1) The word cam refers to an eccentric circular disc. In a four-cycle engine, cams are used to open and close the intake and exhaust valves. The cams are fixed on a camshaft, which is connected via a chain to the crankshaft (thus the position of the cam is fixed in relation to the engine cycle).

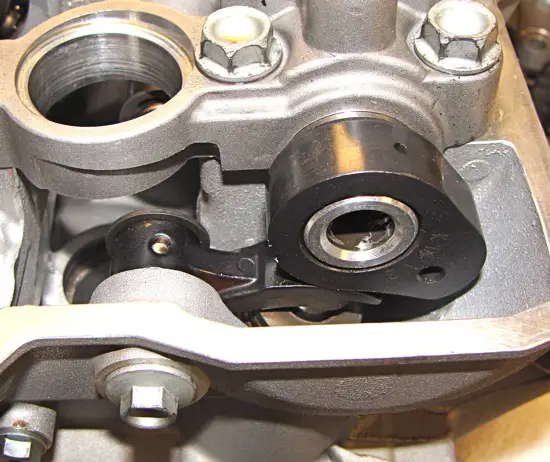

(3) If the camshaft isn’t positioned directly over the valves in the head, the motion can be transferred through a rocker arm. KTM still uses rocker arm engines (sometimes with very short rocker arms called finger followers and sometimes with forked rocker arms). The Honda CRF250/450 uses a forked rocker arm to actuate two valves and a cam-over-bucket design for the other two.

The KTM 450SXF’s single overhead cam (SOHC) forked rocker arms.

(4) Modern motocross bikes have overhead cams. In the era of pushrod engines, the camshaft could be located below the cylinder head. All Japanese motocross bikes, except Hondas, use a dual-overhead-cam (DOHC) configuration that assigns a separate cam for the exhaust valves and intakes valves. Honda’s Unicam design utilizes one cam to actuate a combination of a cam-over-bucket and a forked rocker arm. The KTM 450SXF is also a single cam design with a forked rocker arm. The rest of the KTM lineup utilizes finger follower rocker arm designs that come into contact with the cam lobe early, and ultimately allows for a long valve stroke and more lift.

A finger follower in a KTM engine.

(5) Cams are generally manufactured by two methods. OEM camshafts, which are produced in larger volumes, are cast iron and then nitride-coated. Aftermarket and high-performance camshafts are made out of billet steel. First, they are CNC-machined and then rough ground to a slightly oversized specification. Finally, they are heat-treated and finish ground to the precise measurement.

(6) The cam gear and decompression components are press fit onto the camshaft and bolted in place. Cam phasing is another specification that can tune performance and is adjusted by pressing the cam sprocket onto the camshaft at slightly different angles. Sometimes cam gears have slotted holes that allow the gear to be rotated on the camshaft to change cam timing.

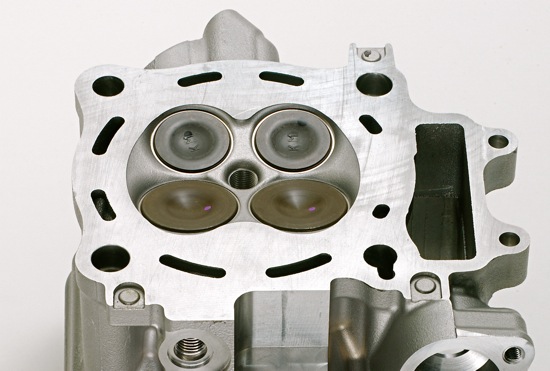

The valves on a CRF250.

(7) The shape of the lobe determines how far the valves open (lift) and how long they stay open (duration). Duration is described in number of crank shaft degrees, counted starting at 1mm and ending at 1mm of lift. The opening and closing ramp is the first and last part of the duration spec and is very important in making the extremely fast (35 feet per second closing speed on a 14,000 rpm engine) valve reciprocation smooth. A valve that slaps hard against its seat won’t last.

(8) When you hear about an engine tuner “grinding” a cam, it’s not a guy in overalls on a bench grinder. High-tech CNC machines allow the tuner to examine and balance the position of cams, valves and pistons in relation to one another. Many tuners add welding material to the cam lobes to increase lift and duration. The welded part is ground to the desired spec.

(9) There are a lot of factors that contribute to a good cam. Switching to a more aggressive cam profile can necessitate stiffer valve springs. Valve float happens when the valves don’t stay in contact with the cam. Maintaining proper valve clearance is crucial in limiting wear and tear. Valve clearance should be checked periodically. Things can easily go wrong during cam installation, too. Putting the chain on the wrong tooth on the cam gear can cause the piston to hit a valve (even when just turning the engine over by hand). One tooth on the cam sprocket equals 10 degrees, and just 3 degrees can make the piston hit a valve.

(10) Why don’t motocross bikes have variable valve timing? There are several different variable valve timing designs in the automotive world, and Kawasaki even has a production street bike utilizing the concept. The truth is, motocross bikes don’t utilize a wide enough rpm range to see much benefit, especially considering the increased weight and complexity.

Comments are closed.