WEIRD STUFF! COATES SPHERICAL ROTARY VALVE ENGINE: There Are No Valves, Just A Series Of Spheres On A Rod: Sort Of A Shish-Kabob

WEIRD STUFF! COATES SPHERICAL ROTARY VALVE ENGINE:

THERE ARE NO VALVES, JUST A SERIES OF SPHERES ON A ROD: SORT OF A SHISH-KABOB

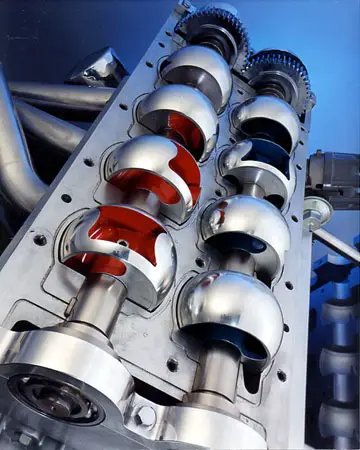

Unlike a conventional piston engine that ignites the fuel and air mixture in the combustion cycle and evacuates the gas byproducts in the exhaust cycle via the rotation of the camshaft and spring-loaded poppet valves (with springs, valve guides, buckets, rockers, shafts and the valves), the Coates Spherical Rotary Valve Engine is made up of spheres rotating on a shaft sandwiched between a split head. These spheres are either chain or belt driven via the crankshaft, much like an overhead camshaft. Each sphere rotates against a matching seal between it and the piston, one for intake and one for exhaust.

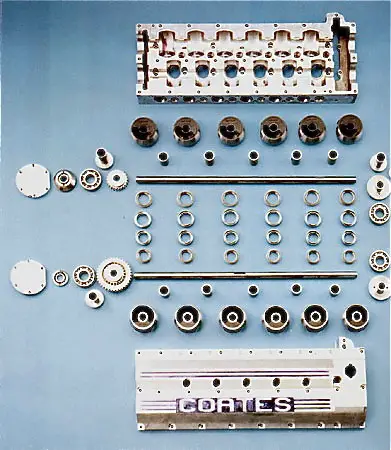

The spheres have cavities and ports machined into them for the induction of fuel and air on the intake stroke, and the evacuation of fired gases on the exhaust stroke. This design performs exactly the same function as poppet valves, but the design eliminates the poppet valves, valve springs, guides, camshaft, pushrods, rocker arms and other smaller parts.

The Coates engine operates with over 100 fewer parts than convention engines. It avoids the problem of oil burning by requiring no oil lubricants for the valves. Moreover, the rotation of the spherical valve heads reduces engine temperature by constantly changing the surface exposed to combustion heat.

The spherical rotary valve design can accommodate higher compression ratios than conventional engines. High compression ratios can be utilized incorporating the Coates more efficient and powerful short-stroke design, while maintaining the desirable characteristics of optimum performance using lead-free gasoline. The maximum rpm on the poppet valve engine were 5700 rpm. Plus, there are fewer components and thus lower costs.

Comments are closed.