FIRST LOOK! 2020 HUSQVARNA OFF-ROAD & DUAL SPORT MODEL RANGE

2020 HUSKY TE150i, TE250i, TE300i, FE350, FE350s, FE501 & FE501s MODEL DETAILS

Husqvarna Motorcycles introduces the entirely new generation MY20 off-road and dual-sport range, delivering the highest levels of dynamic performance and advanced ergonomics that ensure light and controllable machines for unparalleled handling. The new range continues to set the benchmark in terms of technology and performance thanks to a new frame, subframe, shock linkage and bodywork, updated fork and shock settings, and premium components as standard.

The greatly enhanced chassis characteristics are matched to improved power, torque and rideability in both 4-stroke and 2-stroke engines, offering amateurs and professional riders a complete range of models with class-leading performance, power and agility.

The two-stroke range sees the introduction of the new TE150i model which now features pioneering electronic fuel injection technology, like the other TE models, for superior, usable power. The TE250i and TE300i feature updated cylinders for superior performance, while all 4-stroke engines feature updates for increased performance and rideability.

The four-stroke line-up now includes the off-road only FE501 and FE350, which shed the road-going components of their dual-sport counterparts, the FE 501s and FE 350s, and feature more aggressive mapping and a less restrictive power pack, resulting in a lighter overall package and more power to put to the ground.

Highlighting the power and progressive functionality of Husqvarna Motorcycles’ advanced off-road and dual-sport models on the international racing stage, Rockstar Energy Husqvarna Factory Racing’s Billy Bolt and Colton Haaker respectively captured the 2018 World Enduro Super Series and 2019 FIM SuperEnduro World Championship titles.

WHAT’S NEW ON THE 2020 HUSQVARNA OFF-ROAD & DUAL SPORT MODELS

- New frame on all models offering increased longitudinal & torsional rigidity

- TE 150i featuring electronic fuel injection

- New 250 g lighter 2-piece subframe across the model range

- Updated WP XPLOR fork with new mid-valve piston & setting

- Updated WP XACT shock with new main piston & setting

- New shock linkage dimension providing reduced seat height & added control

- All-new exhaust systems for optimal performance & durability

- New seat that places the rider 10 mm closer to the ground

- Improved cooling circuit with radiators mounted 12 mm lower

- Progressive new bodywork design offering new and improved ergonomics

- Updated 4-stroke engines offering improved performance & rideability

- 1° lower mounting on TE 250i/300i engines for improved front end traction

- Updated TE 250i/300i cylinder for superior 2-stroke performance

FEATURES AND BENEFITS | TWO-STROKES AND FOUR-STROKES

Frame

The chrome-moly steel frame is expertly crafted using hydro-formed tubes, which are laser-cut and robot-welded to ensure the highest levels of precision and quality. Harnessing advanced geometries, the frame is developed using specifically calculated parameters of longitudinal and torsional flex. For MY20 the frame features an increase in longitudinal and torsional rigidity providing improved rider feedback, energy absorption and stability.

The cylinder head mountings are now forged aluminum on all models, further improving handling characteristics and comfort while on the TE250i/300i the engine is mounted 1° lower at the swingarm pivot to improve front wheel traction and feeling.

The frame is finished off with a premium blue colored powder coating and standard frame protectors, guaranteeing superior protection and durability.

- Increased longitudinal and torsional rigidity → improved rider feedback, energy absorption and stability

- Forged aluminum cylinder head mountings on all models

- 1° lower mounting on TE250i/300i engines → improved front end traction and feel

- Durable powder coated finish with standard frame protectors

- Composite carbon fiber subframe

- Unique to Husqvarna Motorcycles, the carbon composite subframe showcases pioneering technologies and innovation. Using 70% polyamide and 30% carbon fiber, the new 2-piece subframe saves 250 g for a total weight of just over 2.2 lbs (1 kg). Apart from being robust, specific care is taken by increasing the subframe’s length by 50 mm to create the perfect rigidity for exceptional handling and rider comfort.

- New 2-piece subframe → 250 g saving

- Carbon fiber composite construction → lightweight and robust

- Increased length → exceptional handling and comfort

Swingarm

The hollow cast aluminum swingarm offers optimal stiffness and reliability at the lightest possible weight. Specific machining allows for the chain adjustment slots to be seen from above, allowing for easy maintenance.

- Optimal stiffness and reliability in a lightweight construction

WP XPLOR fork

The WP XPLOR front forks consist of a 48 mm spring type layout with split rebound and damping functions. Compression damping is solely maintained by the left leg and rebound damping solely by the right leg. The result is simple adjustment through optimized easy access clickers (30 clicks) located on the top of each fork leg. Additionally, the standard preload adjusters are refined and allow for a 3-way preload adjustment without the use of tools.

Offering unsurpassed performance and comfort, the MY20 XPLOR forks features an updated mid-valve piston that delivers a more consistent damping function while a new setting allows the forks to operate higher in the stroke, delivering improved rider feedback and bottoming resistance.

- WP XPLOR front fork → 48 mm spring type with split damping function

- Updated preload adjusters

- New mid-valve piston and setting → superior performance, feel and comfort

CNC machined triple clamps

The 22 mm offset black-anodized CNC machined triple clamps offer premium quality as standard on all Husqvarna Motorcycles off-road and dual-sport models. The triple clamps are expertly crafted using superior techniques and materials to provide high levels of quality and reliability. A 2-way handlebar adjustment is standard and allows for customizable ergonomics.

- CNC aluminum → finest quality and reliability

- Adjustable handlebar position → adjustable ergonomics

WP XACT rear shock

Featuring a new main piston and updated settings, balanced with the new front-end set-up and frame rigidity, the WP XACT shock is further perfected to provide advanced damping characteristics while keeping a compact and lightweight design. With a pressure balance inside the shock, damping is consistent for superior rider comfort and handling.

Using the same linkage progression found in the Husqvarna Motocross range, the rear-end now sits lower, improving control and comfort in extreme off-road conditions. Additionally, by using a softer spring rate and increased hydraulic damping, the rear shock maintains comfort with added sensitivity and feel. The component is fully adjustable and delivers unrivalled traction, feeling and energy absorption. Rear wheel travel is 300 mm.

- New main piston and setting → balanced with new front-end set-up and frame rigidity

- New Linkage progression → improved control and comfort

- Pressure balance → consistent dampin

- 300 mm wheel travel

Magura hydraulic clutch

The reliable, high-quality, German-made clutch system guarantees even wear, near maintenance-free operation and perfect action in all conditions. Lever free-play is constantly compensated so that the pressure point and function of the clutch remain constant in cold or hot conditions, as well as over time.

- Magura hydraulic clutch → perfect action in all conditions

Magura Brakes

The Magura braking system offers the highest level of braking performance while specifically tailored for off-road riding to deliver exceptional action and feel. The 260 mm front and 220 mm rear waved brake discs by GSK keep weight to a minimum and offer complete braking confidence.

- Magura brake calipers and high-performance GSK discs → superior stopping power with unsurpassed sensitivity and action

ProTaper handlebars

ProTaper handlebars are second to none for function and style. Manufactured to exacting standards, the ProTaper handlebars features class-leading fatigue resistance while adding minimal weight. ProTaper logos are chemically applied and are scratch and peel resistant.

- ProTaper handlebars → class-leading function and style

Grips and throttle assembly

The ODI lock-on grip on the left side requires no gluing, while on the right, the vulcanized grip features an innovative integrated throttle mechanism. The assembly has easy free-play adjustment and, by changing a cam, throttle progression can be altered.

- Throttle assembly and ODI grips → easily alter throttle progression; easy grip mounting without glue

Map switch, traction control

Designed for easy operation, the standard map switch on the off-road FE models selects between 2 EFI maps and activates the traction control. Traction control features an updated setting offering improved traction and control on slick terrain.

Traction control is selected to an on or off position from the switch and functions by analyzing throttle input from the rider and the rate at which rpm increases in the engine. If the rpm increases too quickly, the EMS registers a loss of grip and reduces the amount of power to the rear wheel ensuring maximum traction.

Additionally, all 2-strokes are also fitted with a standard map switch allowing selection between 2 ignition curves based on conditions or rider preference.

- Standard handlebar map switch → alter engine characteristics according to conditions and rider preference

- Traction control → optimal traction in all conditions

Engine Management System (EMS)

Apart from controlling EFI parameters on the four-strokes, the Keihin EMS features selectable engine maps via the switch on the handlebar, as well as traction control. Combined with the gear sensor, power delivery is tailored for each gear.

The EMS features new map settings adapted to the new engine characteristics, exhaust and airbox design to deliver the perfect response and control in ever-changing conditions.

- Keihin EMS → smaller, lighter and faster at processing engine data for more efficient engine management

New map settings

Gear sensor → specific engine maps for each gear

On the two-strokes, the EMS features an electronic control unit (ECU) which is responsible for a number of functions. The unit determines the ignition timing, the amount of fuel & oil injected and additionally receives information from the throttle position sensor, ambient air & intake pressure sensors as well as crankcase pressure and water temperature sensors to adapt values and make corrections for automatic temperature and altitude compensation eliminating the need to change carburetor jetting as in the past.

- 2-stroke EMS → modern engine management eliminating the need for jetting changes

Throttle body

The four-stroke range features a 42 mm Keihin throttle body. The injector is positioned to ensure the most efficient flow into the combustion chamber. To ensure optimal throttle response the throttle cable is mounted directly without a throttle linkage, to provide more immediate throttle response and feeling. A new throttle cable routing eases maintenance allowing the cable to be accessed more seamlessly.

- Throttle body → 42 mm, injector positioned for optimal flow, more immediate throttle response thanks to direct cable mounting

- New throttle cable routing → more seamless access

The two-strokes use a 39 mm throttle body, which regulates the amount of air entering the engine via a butterfly valve operated by dual throttle cables connected to a new handlebar throttle assembly. Unlike 4-stroke throttle bodies, fuel is not introduced at this point, but rather 2-stroke oil is mixed with the air entering the engine to lubricate the crankshaft, cylinder & piston. Additionally, a throttle position sensor (TPS) relays airflow data to the ECU, which in turn calculates the amount of oil and fuel delivered to the engine while a bypass screw regulates the idling speed and a cold start device opens a bypass providing more air for cold starts.

- 39 mm throttle body → regulates air flow, TPS relays airflow data

Exhaust system

Tailored specifically for each model using an innovative 3D design process, the two-stroke header pipes offer further improvements in geometry and performance. The TE250i/300i header pipe is 25 mm narrower and offers more ground clearance making it less susceptible to damage while a corrugated surface makes the header pipe more durable and resistant to damage from rocks and other hazards found on the trails. The 2-stroke silencers feature a new aluminum mounting bracket with new internals and less dense packaging material for more efficient noise damping and a weight saving of 200 g.

The 4-stroke exhaust systems are expertly designed to deliver leading performance at the lowest possible weight. The header pipe is separated in two pieces, designed to be as compact as possible. The new header pipe also features a new joining position allowing it to be removed without detaching the rear shock. The new muffler is shorter and more compact without increasing the noise level. The component is crafted from lightweight aluminum and is stylishly finished in a new coating that proudly displays the Husqvarna logo.

- New exhausts → lightweight, optimal performance

- Corrugated surface on TE 250i/300i → more durable against damage

- New header joining position on 4-stroke → removable without detaching rear shock

Electric start and wiring harness

All TE and FE models come standard with an electric starter. The system uses a compact and lightweight Li-Ion battery, which is 2.2 lbs (1 kg) lighter than a conventional battery. With several years of experience using electric starters on Husqvarna Motorcycles’ off-road models, the proven reliability is second to none, ensuring a quick and seamless start in all conditions.

Additionally, an optimized wiring harness improves the packaging and concentrates all needed electrical components in a common area for easy accessibility. This improved packaging also allows the seat base to be moved downward reducing the seat height by 10 mm.

Integrated cooling system and radiators

The radiators are expertly crafted using high strength aluminum. CFD (Computational Fluid Dynamics) is used to channel air through the radiators more efficiently and provide optimal cooling in all conditions. The system is integrated into the frame allowing for improved cooling by channeling coolant through the frame while eliminating the need for additional hoses. New to the system is a 4 mm larger center tube that runs through the frame. The new tube reduces the pressure at this point in the system allowing for a more consistent coolant flow.

Additionally, the new radiators are mounted 12 mm lower, closer to the center of gravity for improved handling agility.

All four-stroke models are fitted with radiator fans as standard. 2-stroke radiator fan kits are available from the Accessories catalogue.

- Integrated cooling → maximum efficiency in minimum space

- New central tube → more consistent coolant flow

Fuel tank

The polythene fuel tanks incorporate a quick release filler cap and an integrated fuel pump. The fuel pump is optimized with a new internal line routing directly from the pump to the flange, for improved fuel flow. Additionally, the external fuel line has moved inward making it less exposed and susceptible to damage. A fuel level sensor is incorporated on all models.

Airbox and tool-less air filter access

The airbox is designed with precisely positioned inlet ducts aimed at preventing air deformation to ensure maximum airflow and maximum filter protection. The air filter is easily accessed without tools by removing the left side panel. Easy maintenance is guaranteed by the Twin Air filter and filter cage design, which features a simple fail proof mounting system for secure and accurate filter installation.

- Airbox → maximum air flow and filter protection

- Filter mounting system → secure protection against dirt

- Tool-less filter access → easy and fast maintenance

Wheels

Black high-strength alloy rims by D.I.D with laser engraved logos come on the off-road models while the 2020 dual-sport machines feature high-end GIANT rims. Both are coupled to CNC machined hubs using lightweight spokes and silver anodized aluminum nipples, which incorporate a new design, reducing the frequency of spoke checks and maintenance.

- Lightweight but strong and reliable construction → minimum unsprung weight

Tires

The off-road range features Dunlop AT81 tires, offering advanced grip in a wide variety of different terrain. The dual-sport models feature Continental TKC80 tires, providing excellent grip both on and off-road.

Bodywork

The new generation features fresh, new bodywork. This new bodywork clearly showcases Husqvarna Motorcycles’ pioneering design direction in off-road motorcycling. Aside from the Swedish inspired design, the ergonomics are tailored to deliver greater comfort and control, enabling riders to perform at their highest level for extended periods of time. Developed from extensive testing, the contact points have been slimmed down, making movement between riding positions increasingly seamless.

The new seat profile (thanks to the improved packaging of the wiring harness) reduces the total seat height by 10 mm, which when combined with the new seat cover deliver superior comfort and control in all conditions.

- New bodywork → distinctive looks, modern design and graphic

- Ergonomics → confidence-inspiring riding position in all riding situations

- Seat → Reduced seat height by 10 mm with improved comfort and control in all conditions

HUSKY TE150i TWO-STROKE

Lightweight and incredibly nimble, the TE150i features the latest two-stroke fuel injection technology, giving it all the convenience of modern four-strokes at a fraction of the weight. The TE150i is fitted with an electric starter as standard for easy starting in challenging situations. Additionally, the new chassis offers precise flex characteristics, and in combination with WP suspension offers advanced handling characteristics and comfort in the most challenging conditions.

Engine

Using the latest two-stroke fuel injection technology, the TE 150i has all the convenience of modern 4-strokes, eliminating the need to premix fuel or adjust jetting at different altitudes. The engine uses specific shaft arrangements designed to harness the rotating mass of the engine in the ideal center of gravity. The lightweight and compact engine provides a powerful power delivery while maintaining the inherent low-cost maintenance of a 2-stroke.

- Latest generation 2-stroke → fuel injection, powerful, light and compact

- Mass-centralization → significant benefits in handling and maneuverability

Cylinder and piston

The cylinder has a 58 mm bore, which features an innovative power valve design that delivers controllable power throughout the rpm range. The piston is designed to perfectly match the optimized combustion chamber contour delivering the highest level of two-stroke performance.

Additionally, the cylinder features two inlet positions located on the transfer ports at the rear of the cylinder where a pair of fuel injectors are mounted. The injectors deliver the fuel downwards into the transfer port, which guarantees excellent atomization with the air travelling upward to the combustion chamber. This ensures a more efficient combustion resulting in reduced fuel consumption and emissions.

- Cylinder and piston → revised combustion chamber contour

- Fuel injection → increased efficiency and reduced emissions

CrankshaftWith a 54.5 mm stroke, the crankshaft is perfectly balanced to reduce vibrations. The weighted flywheel attached to the crankshaft provides abundant torque and controllable off-road specific power while the larger alternator provides all the power needed for the EFI system.

- Lightweight crankshaft → very little vibration

- Larger alternator → increased electrical power to power EFI system

Crankcases

The crankcases are manufactured using a high-pressure die cast production processes resulting in a thin wall thickness and minimal weight.

To centralize mass, the layout features a shaft arrangement precisely positioned to harness rotating masses at the ideal center of gravity. The reed block features optimized carbon reeds for improved sealing.

- High pressure die-cast production process → thin walls resulting in light weight

- Shaft arrangement → ideal mass centralization

- New reed valves → better sealing

Oil tank & pump

The TE150i features an electronic oil pump, which feeds vital two-stroke oil into the engine to keep it lubricated. The pump is located just below the oil tank and feeds the oil via the throttle body, meaning the oil is not mixed with the fuel, eliminating the need for pre-mixing as on traditional two-stroke engines. The pump is controlled by the EMS and delivers the optimal amount of oil according to the current rpm and engine load. This reduces waste as well as excessive smoke being transmitted from the exhaust.

The oil tank is located beneath the fuel tank and is connected to a filler hose, which runs through the upper member of the frame to a filler cap, conveniently located for easy refills. The tank capacity is 0.7 liter and is fitted with a sensor which illuminates a warning visible to the rider when the oil needs to be refilled.

- Oil pump and tank → convenient solution, eliminates pre-mix

Gearbox

The TE 150i is fitted with a PANKL 6-speed wide range gearbox. The off-road specific ratios are tailored to the 150 cc power delivery. An innovative gear shifter reduces dirt build up, ensuring perfect operation in all conditions.

PANKL 6-speed gearbox → specific off-road gearing

Innovative gear shifter → prevents dirt build up ensuring precise control

DS clutch

The TE 150i features a new DS (Diaphragm Steel) clutch. The exclusive characteristics of this system include a single diaphragm steel pressure plate instead of traditional coil springs. The clutch basket is a single-piece CNC machined steel component that allows the use of thin steel liners and contributes to the compact design of the engine.

HUSKY TE250i / TE300i

The TE250i and TE300i incorporate the perfect balance between usable two-stroke power and nimble lightweight handling and feature revolutionary two-stroke electronic fuel injection. This new-age technology redefines 2-stroke competition motorcycles, cementing their position in the off-road segment for the foreseeable future. Both the TE250i and TE300i add convenience and simplicity, doing away with premixed fuel and jetting changes. It delivers efficiency and low emissions while retaining the simple character and inexpensive ownership of a two-stroke.

Engine

The 250cc and 300cc two-stroke engines have long been the best combination of unsurpassed power and lightweight construction. The simplicity and low maintenance cost of the two-stroke engine have made it a favorite among off-road riders for generations. Both the TE250i and TE300i feature a pioneering electronic fuel injection system. This comprises of a set of fuel injectors positioned at the transfer ports, which deliver the ideal amount of fuel to the engine in all conditions. This not only reduces fuel consumption and emissions but also provides a clean and smooth power delivery, giving the beloved 2-stroke the edge over the competition.

Additionally, the 250cc and 300cc engines have an advanced construction featuring shaft arrangements precisely positioned for greater mass centralization, a counter balancer shaft to reduce vibration, a twin-valve controlled power valve and 6-speed transmission.

Cylinder

The 66.4 mm bore cylinder (72 mm on TE300i) features a twin valve-controlled power valve system, which delivers smooth and controlled power throughout the rpm range.

For 2020, the exhaust port timing is improved by fully machining the exhaust port window, and with the combination of an optimized power valve drive and adjuster, the function and overall performance of the power valve are improved.

Additionally, the cylinder features two inlet positions located on the transfer ports at the rear of the cylinder, where a pair of fuel injectors are mounted. The injectors deliver the fuel downwards into the transfer port, which guarantees excellent atomization with the air travelling upward to the combustion chamber. This ensures a more efficient combustion resulting in reduced fuel consumption and emissions.

- Dual fuel injectors → excellent atomization, reduced fuel consumption

- Power valve → Machined port window, new drive and adjuster

Piston

The lightweight piston is perfectly matched to the cylinder and transmits minimal oscillating mass, ensuring high levels of reliability and performance.

Engine casings

The TE250i and TE300i engines are designed to improve mass centralization. As a result, the lightweight, die-cast engine casings are developed to accommodate the shaft arrangements in the ideal position, centralizing oscillating mass and improving ride-ability. Also, the counter balancer shaft is integrated in a very compact manner, having little effect on the overall design while reducing vibrations.

Additionally, for 20220, a new water pump casing improves cooling by optimizing the flow of coolant.

- Die cast engine casings → mass centralization, improved handling

- New water pump casing → improved cooling

Counter balancer shaft

The engine houses a laterally mounted counter balancer shaft. The balancer significantly reduces vibration resulting in a smoother and more comfortable ride.

Crankshaft

The crankshaft features a 72mm stroke and is balanced in conjunction with the counter balancer shaft for minimum vibration. By incorporating a heavier ignition rotor, the crankshaft produces more inertia than its motocross counterpart, which improves control in the lower rpm range.

Gearbox

A 6-speed PANKL gearbox features off-road specific ratios while an innovative shift lever reduces dirt build up, guaranteeing easy operation in all conditions.

DDS Clutch

The TE 250i and TE 300i feature a DDS (Damped Diaphragm Steel) clutch. This means the clutch uses a single diaphragm spring instead of the more common coil spring design, resulting in a much lighter clutch action. This design also incorporates a damping system, which increases both traction and durability. The new model features a new, lighter basked and reworked inner hub, which guarantees better oil supply and cooling to the clutch.

Combined with the Magura hydraulic system guarantees a light and smooth clutch feeling which is almost maintenance and adjustment free.

Oil tank & pump

The TE250i and TE300i feature an electronic oil pump, which feeds vital 2-stroke oil into the engine to keep it lubricated. The pump is located just below the oil tank and feeds the oil via the throttle body, meaning the oil is not mixed with the fuel eliminating the need for pre-mixing as on traditional 2-stroke engines. The pump is controlled by the EMS and delivers the optimal amount of oil according to the current rpm and engine load. This reduces waste as well as excessive smoke being transmitted from the exhaust.

The oil tank is located beneath the fuel tank and is connected to a filler hose, which runs through the upper member of the frame to a filler cap conveniently located for easy refills. The tank capacity is 0.7 liter and is fitted with a sensor, which illuminates a warning lamp visible to the rider when the oil needs to be refilled.

- Oil pump and tank → convenient solution, eliminates pre-mix

HUSKY FE350 & FE350s

The FE 350 and FE 350s are known for their versatility in all types of terrain. With a lightweight chassis and ample performance, the 350 possesses a 450-rivalling power-to-weight ratio while keeping the light and agile feel of a 250. Combined with class leading WP suspension, selectable engine maps on the off-road model and Magura hydraulic clutch, the FE 350 and FE 350s feature an array of premium components for unsurpassed quality and reliability.

Engine

The 350 cc engine is designed to be powerful, light and compact. All major components and shaft arrangements are carefully positioned to best suit the performance and handling characteristics of the overall package. As a result, the engine weighs only 61.5 lbs (27.9 kg) while retaining its torquey nature, making the 350 engine accessible for both professionals and amateurs.

Cylinder head

The cylinder head, which is now 200 g lighter for 2020, features advanced technology aimed at reducing weight and drag. To accomplish this, the twin overhead camshafts rotate on a low friction surface while the four lightweight titanium valves (36.3 mm intake and 29.1 mm exhaust) are actuated by finger followers using a DLC (Diamond Like Carbon) coating. For MY20, the new camshafts feature revised timing, further perfecting performance and responsiveness. The 350 also features a new cylinder head cover, spark plug, and spark plug connector.

Cylinder and piston

Both the FE350 and FE350s feature a forged bridged-box-type piston made by CP. The cylinder and piston are produced from high strength aluminum resulting in outstanding performance and reliability. The cylinder head features new cooling architecture and with a new head gasket increases the compression ratio 12.3:1 to 13.5:1.

Crankshaft

With a new oil supply, the plain big end bearing features two force-fitted bearing shells ensuring maximum reliability and durability, guaranteeing long service intervals of 135 hours.

Counter balancer shaft

In order to counteract the rotational force of the crankshaft and reduce vibration, both models feature a multifunctional counter balancer shaft that also drives the water pump and timing chain.

Crankcases

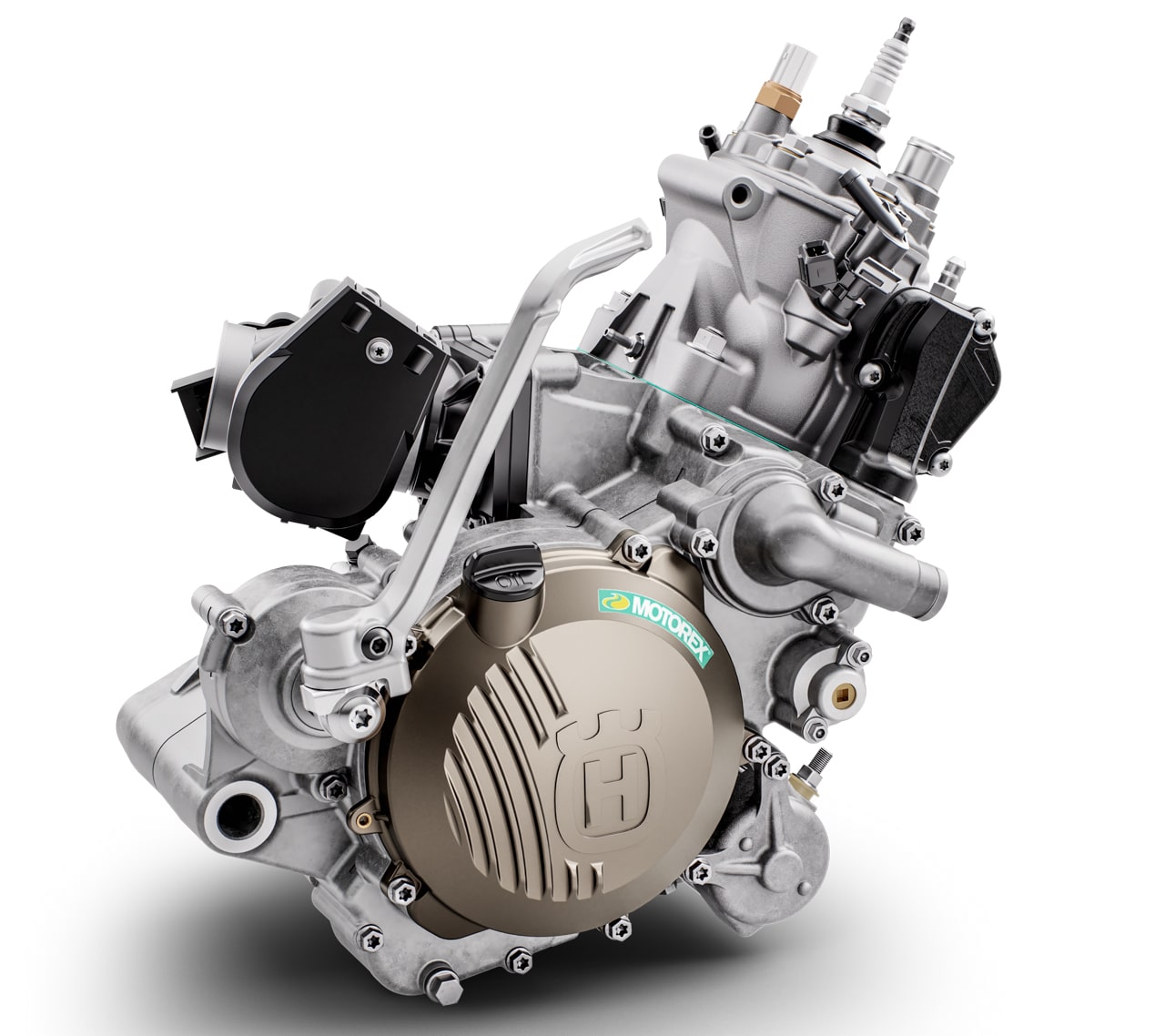

The engine is designed to be compact while centralizing rotating masses. As a result, the crankcases are engineered to house the shaft arrangements at the ideal center of gravity and now also integrate the oil supply to the main bearing. The casings are manufactured using a high-pressure die cast production process and are further optimized to reduce weight while retaining exceptional reliability. The iconic Husqvarna logo adorns the bronze finished crankcase covers.

Gearbox

The new 6-speed gearbox from PANKL uses specific wide-range off-road type gearing. Additionally, a gear sensor allows the EMS to tailor a specific engine character suited for each gear.

DDS clutch

The DDS (Dampened Diaphragm Steel) clutch system includes a single diaphragm steel pressure plate instead of traditional coil springs, making the clutch pull very light while also integrating a damping system for better traction and durability. The clutch basket is a single-piece CNC machined steel component that allows the use of thin steel liners and contributes to the compact design of the engine. The Magura hydraulic system ensures perfect action in all conditions.

HUKSY FE501 & FE 501s

The FE501 and FE501s feature class leading technology and premium components as standard. The chromium molybdenum frame is expertly crafted to offer the ideal flex while the powerful engine features shaft arrangements aimed at balancing mass centralization and handling. Combined with traction control (FE 501), WP suspension, progressive rear linkage and the most powerful engine in the segment, these machines hold no compromise in pure performance and precision.

Engine

Weighing only 64.8 lbs (29.4 kg), the engines are not only light and compact but feature the latest technology available, offering unequalled performance, ride-ability and reliability. Additionally, the engine is suited specifically for off-road and dual-sport riding with a standard electric start, 6 speed wide ratio gearbox and, on the off-road only FE 501, an array of advanced electronic rider aids such as traction control and the handlebar map select switch, delivering accessibility on a variety of terrain and skill levels.

Cylinder head

The new SOHC cylinder head is more compact while being 15 mm lower and 500 g lighter. As a result of the new compact design, the camshaft is now closer to the center of gravity, which significantly improves handling while shorter valve timing improves bottom end performance and responsiveness. The new camshaft features an improved cam surface and with new rocker arms actuates four lightweight valves, which are shorter, fitting the new compact design. The diameter of the titanium intake valves is 40 mm (33 mm on the streel exhaust valves). Low-friction DLC coating on the rocker arm and shorter low-friction chain guides offer the optimum efficiency and reliability.

Cylinder and piston

The lightweight aluminum cylinder features a 95 mm bore and a new lightweight Konig forged bridge-box-type piston perfectly matched to the high compression combustion chamber. The piston is attached to a 10% lighter piston pin. This combination produces very little oscillating mass, which significantly reduces vibration and increases rider comfort. The compression ratio has increased from 11.7:1 to 12.75:1.

Crankshaft

A plain big end bearing comprising of two force-fitted bearing shells and ensure maximum reliability and durability, guaranteeing long service intervals of 135 hours.

Counter balancer shaft

In order to counteract the rotational force of the crankshaft and reduce vibration, the engine uses a multifunctional counter balancer shaft, which also drives the water pump.

Crankcases

The revised crankcases further reduce the engine weight by 300 g and are designed to house the shaft arrangements and internals of the engine at the ideal position, centralizing masses for a lightweight handling feel

High-pressure die cast production processes result in a thin but reliable wall thickness and keep weight to a minimum.

Gearbox

The lightweight 6-speed gearbox ensures smooth and precise shifting thanks to a low friction coating on the shifting fork. The gear lever features a design that prevents dirt build-up and keeps the lever tip in its original position even in the toughest conditions while a gear sensor allows for specific engine maps in each gear.

DDS clutch

The FE501 and FE501s feature a DDS (Dampened Diaphragm Steel) clutch. The exclusive characteristics of this system include a single diaphragm steel pressure plate instead of traditional coil springs making the clutch pull very light while the integrated damping system improves traction and durability. The clutch basket is a single-piece CNC machined steel component that allows the use of thin steel liners and contributes to the compact design of the engine. The Magura hydraulic system ensures perfect action in all conditions.

Comments are closed.