INSIDE THE SECRET R&D LIFE OF THE 2014 YAMAHA YZ250F

By Jody Weisel

One of the perks of being an MXA test rider is that you occasionally get to ride new bikes before they hit the production line. And, often you get to ride future designs while they are still in its embryonic stage. It is a marvelous feeling to pull through the locked gates of a racetrack for the sole intent of testing bikes that don’t exist yet. Although factory test riders and MXA test riders have the same jobs, we stand on different sides of the demilitarize zone. They make ’em and we break ’em.

But a truce is called when the factories are interested in feedback and the MXA wrecking crew is looking for insight. In most of these cases, neither of us can tell anyone about it. We get to test secrets bike with the provision that we don’t write about it.

To me, this goes against the grain of what Motocross Action is all about. We have built our reputation on telling the truth about the bikes we ride, so it sticks in my craw to not be able to write about what we did, saw and felt. But, we made a deal, a “you scratch my back and I’ll scratch yours” arrangement, and MXA must live up to our end of the bargain. There is something in it for all involved. The factory test engineers get a preview of what their worst critics think about their hard work and MXA gets a heads-up on what soon will be rolling off the assembly line.

THIS SYMBIOTIC RELATIONSHIP BENEFITS BOTH OF THE MANUFACTURER AND MXA?BUT IT DOESN’T BENEFIT YOU. WE KISS, BUT WE DON’T TELL.

This symbiotic relationship benefits both the manufacturer and MXA?but it doesn’t benefit you. We kiss, but we don’t tell. So, when Yamaha ask us to come out to try the 2014 Yamaha YZ250F Pre-Pro a couple months before it went on the showroom floors?we happy about it?but it still didn’t represent a bike that we could write about. Not that Yamaha barred us from writing about it, but the caveat was that it was pre-pro. It wasn’t a production bike and at the time that we rode it, it was almost three months away from being a production bike. Historically, pre-pros have been better than the production bike or worse than the production bike?but rarely identical to the production bike. So, although we were happy to ride it, we reserved judgment for the real deal.

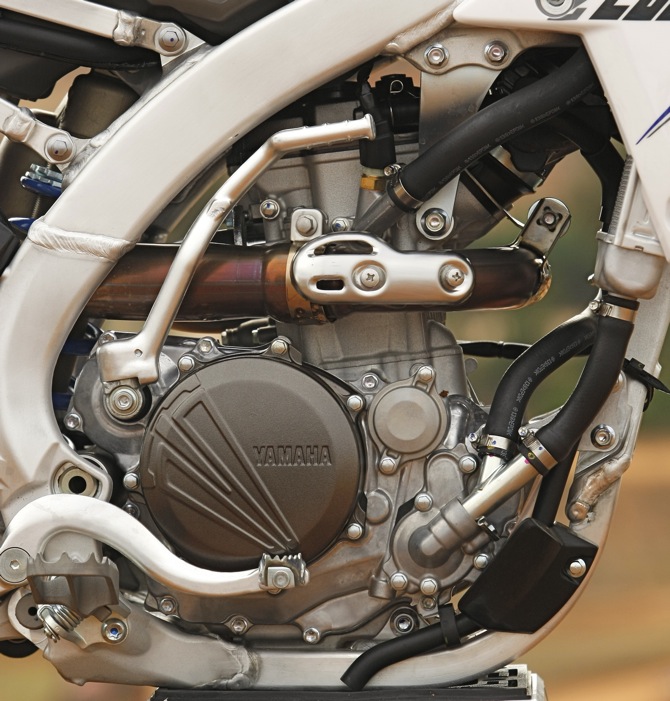

But, the simple fact that we were riding the 2014 YZ250 months before it was scheduled to go on sale meant that behind the doors of the Yamaha R&D department there was a lot going on. So, we decided to dig into the development cycle of a new motorcycles?in this case, the 2014 Yamaha YZ250F.

YOU NEED TO UNDERSTAND THAT THERE ARE FOUR DIFFERENT TYPES OF NEW MODELS

STEP ONE: All R&D projects are not the same. You need to understand that there are four different types of new models. They run the gamut from mild to wild.

The BNG bike: BNG stands for “Bold New Graphics” and the term is applied to bikes that get no mechanical changes?only cosmetic ones. 2014 models that are BNG models include the Kawasaki KX450F, Honda CRF450, Yamaha YZ125 and YZ250, and Suzuki RM-Z250 and RM-Z450.

The Revision bike: Next on the hierarchy of new models is the revision bike. Revisions include new valving, bodywork, brake pads, spring rates and BNG, but it is basically the same bike as the year before with sensible updates. The 2014 KTMs and KX250F are the primary revision bikes of 2014.

The Remake bike: A remake is an existing model that gets major revisions. What constitutes a major remake? A completely new engine, frame or suspension. There were no Remake models produced in 2014.

The Ground-Up bike: The 2014 Yamaha YZ250F is a completely new, first-year, introduction model. As a rule of thumb, manufacturers typically introduce Ground-Up design every four model years. Ground-Up models for 2014 include the Honda CRF250, Kawasaki KX85, Yamaha YZ450F and YZ250F.

What is unique about the 2014 Yamahas is that they bit the bullet and produced two totally new Ground-Up bikes in the same year. The costs of doing this are staggering. Not only did Yamaha have to double the R&D budgets for 2014, but the engineering, testing and development staffs were spread thin as they worked simultaneously on two distinctly new motocross models. Most manufacturers release one new model at a time.

THE 2014 YAMAHA YZ250F STARTED LIFE BACK IN NOVEMBER OF 2009

STEP TWO: The 2014 Yamaha YZ250F started life back in November of 2009. Step one was a meeting with Yamaha’s design, marketing and engineer staffs, under the leadership of YZ Project Leader Hiroshi Ito. The preliminary meeting was to discuss tactics, analyze what was needed and discuss the budget of the proposed 2014 model.

STEP THREE: With a budget approved and the engineering staff assigned, the second step was to build a proof of concept test mule. This is a relatively small program?that will most likely culminated in no more than four handmade engines. The engines are roughed out from CNC-machined, sand cast and billet parts. Even the cranks, trannies and moving parts are one-off items. From the time of the first meeting in November of 2009, it took the R&D staff three months to build the proof-of-concept bike.

STEP FOUR: By May of 2010 the proof-of-concept bike was ready to ride. It stayed in Japan, and American test riders and engineers were flown into run it through its paces. It is never assumed that the proof-of-concept bike would be a smash hit, because once the testing is done another three months was needed to build an improved version. It was still made from sand cast, machined and billet parts (even the parts of the frame and swingarm that will be forged are machined from solid billets of aluminum at this stage). The second generation of the concept bike was sent to the USA for intense evaluation. After these test the bike and the check list of needed improvement were sent back to Japan for the next step.

A YEAR AFTER THE PROJECT WAS STARTED, YAMAHA WAS READY TO MAKE A TRUE-TO-LIFE PROTOTYPE. IT WENT THROUGH A COUPLE GENERATIONS

STEP FIVE: A year after the project was started, Yamaha was ready to make a true-to-life prototype. It went through a couple generations, but with each new edition, more die cast and forged parts were integrated into the bike. By the end of 2011 all of the sand cast parts had been phased out of the R&D project and the bike was closer to being ready. A lot of the testing at this stage was for durability as much as performance.

STEP SIX. Amazingly, almost four years after the project was started, the Final Prototype was ready to go in January of 2013. The final prototype as defined by finalized molds, castings, forgings and extrusions. The tunable parts were still in limbo as cam profiles, compression ratios, EFI settings, spring rates, flywheel inertia, suspension valving and other adjustable factors were still being determined. By the end of final prototype testing every piece, part and setting must be set in stone so that the parts can be ordered and the assembly line stocked.

THE PRE-PRO STAGE IS A DRILL OF SORTS. AS A FINAL FAIL-SAFE YAMAHA SETS UP A PSEUDO YZ250F PRODUCTION LINE AND RUNS OFF A BATCH OF 50 UNITS

STEP SEVEN: The Pre-Pro stage is a drill of sorts. As a final fail-safe Yamaha sets up a pseudo YZ250F production line and runs off a batch of 50 units. The purpose of these bikes was to fine tune the assembly line and production process so that when the actual assembly begins it would run smoothly. The 50 Pre-Pro bikes were sent in allotments to the American, Canadian, Australian and European distributors. When the distributors get the bikes they can use them for last-minute testing, promotion or advertising.

Although it is possible to make a change to a Pre-Pro, that is very rare. Perhaps mapping, gearing or clicker settings could be changed, but anything bigger than bolting on an existing part would cause a delay in the production schedule. The United States gets approximately 15 Pre-Pro YZ250Fs. Which are disperse through the company to the racing, advertising, press relations, promotions and testing departments. One Pre-Pro is kept in pristine condition to be used as a check model for comparison against the actual production bike.

IN THE END, ALL OF THE PRE-PROS MUST BE DESTROYED. IN FACT, THE GOVERNMENT INSISTS THAT THE BIKES BE CUT UP AND HAVE PHOTOS SHOT OF THE CHOPPED-UP HEAD TUBE

In the end, all of the Pre-Pros must be destroyed. In fact, the government insists that the bikes be cut up and have photos shot of the chopped-up head tube with frame numbers on it and the lacerated engine cases with the engine number visible. Yamaha keeps these photos on file for eight years.

STEP EIGHT: In fact, step eight was letting the MXA wrecking crew ride the Pro-Pro YZ250F about three months before it was destined to go on sale. However, from Yamaha’s point of view, step eight was to take all they learned since November of 2009 and have it roll down the assembly line four years later.

There you have it! The 2014 Yamaha YZ250F started life in four years ago, but just hit the showrooms in November of 2013. The R&D cycle is a long journey.

Comments are closed.