WE BUILD A BETTER, FASTER HONDA CRF450

MXA BUILDS A BETTER, FASTER HONDA CRF450

The 2019–’20 Honda CRF450 is the fastest bike of its class, and it is the second generation of the CRF450 after major changes were made to the model in 2017. Three years ago Honda made a big push to get back to its winning ways. Honda of Japan took back its racing program from American Honda and put HRC in charge. Honda rehired Erik Kehoe as the team manager and spent big bucks to get Ken Roczen on the factory Honda roster.

Honda’s 2007 and 2008 CRF450s are universally considered to be the best CRF450s ever. When 2009 rolled around, Honda’s engineers hoped to improve the already-popular model, but, unfortunately, they went the wrong direction. The Cab Forward design completely changed the CRF450 for the worse, and budget constraints forced Honda to stick with the failed concept from 2009 to 2016. When the time came to think about a new design for 2017, Honda listened to its customers, and as a result, the all-new 2017 CRF450 was more like the 2008 bike than any model they had sold over the previous eight years. During 2018 and 2019, Honda’s R&D department continued to evolve for the better. The 2019 Honda CRF450 pumped out 3 more horses than the YZ450F, which was a distant second in the horsepower rankings. It also revved 33-percent broader than any other CRF450 while making considerably more horsepower above 9000 rpm. MXA’s test riders loved this bike in stock form, but as with every bike, we still found issues to fix and came up with ideas to make it better. Here are the steps we took to build a better 2019 CRF450.

The MXA test riders enjoyed the hard-hitting 2019 CRF450 powerplant, but there were lots of naysayers who wanted the power to be smoother and more usable. There has always been a constant search to find the perfect balance between fast and usable. How fast is too fast? At what point does too much power actually slow down lap times rather than speed them up? Ever since the era of 500cc two-strokes, people have been wondering the same thing. Thankfully, modern programmable ECUs make the perfect powerband a possibility.

If you’ve ever ridden a 2019–’20 CRF450, you know that the power hits hard on the bottom end, mellows out momentarily, and then kicks like a country mule. The stock power delivery is a hoot on a smooth track, but once it gets rough, the hard-hitting powerplant generates a plethora of mistakes from the rider. This fact was brought home when we tested the 2019 Roczen Edition Honda CRF450WE. It gave up some of the peak horses for a filled-in and smoother power curve from low to mid. The slight increase in power down low produced less hit and a more usable powerband. The Roczen Edition CRF450 allowed us to ride faster and longer, thanks in large part to a different ECU map

GUESS WHAT? WITHIN THE FIRST LAP IT WAS CLEAR THAT SOMETHING WAS WRONG. ACTUALLY, WE KNEW EXACTLY WHAT WAS WRONG.

For our CRF450 project, we wanted to keep the mega horsepower, but make it more pleasant on the track. To accomplish this, we made three engine upgrades before heading over to Twisted Development to let them handle the electronic side of it. Our three mods were motorcycle mechanics 101. First, we opened up the top-end and swapped out the stock piston for a high-compression JE Pistons Pro Series 14:1 piston. Now, you might wonder why we would want more hit from a high-compression piston when our stated goal was to lessen the hit. We felt that we had to “get to give.” We wanted more power from low to mid so that Twisted Development’s Jamie Ellis had more meat to work with when he started mapping it.

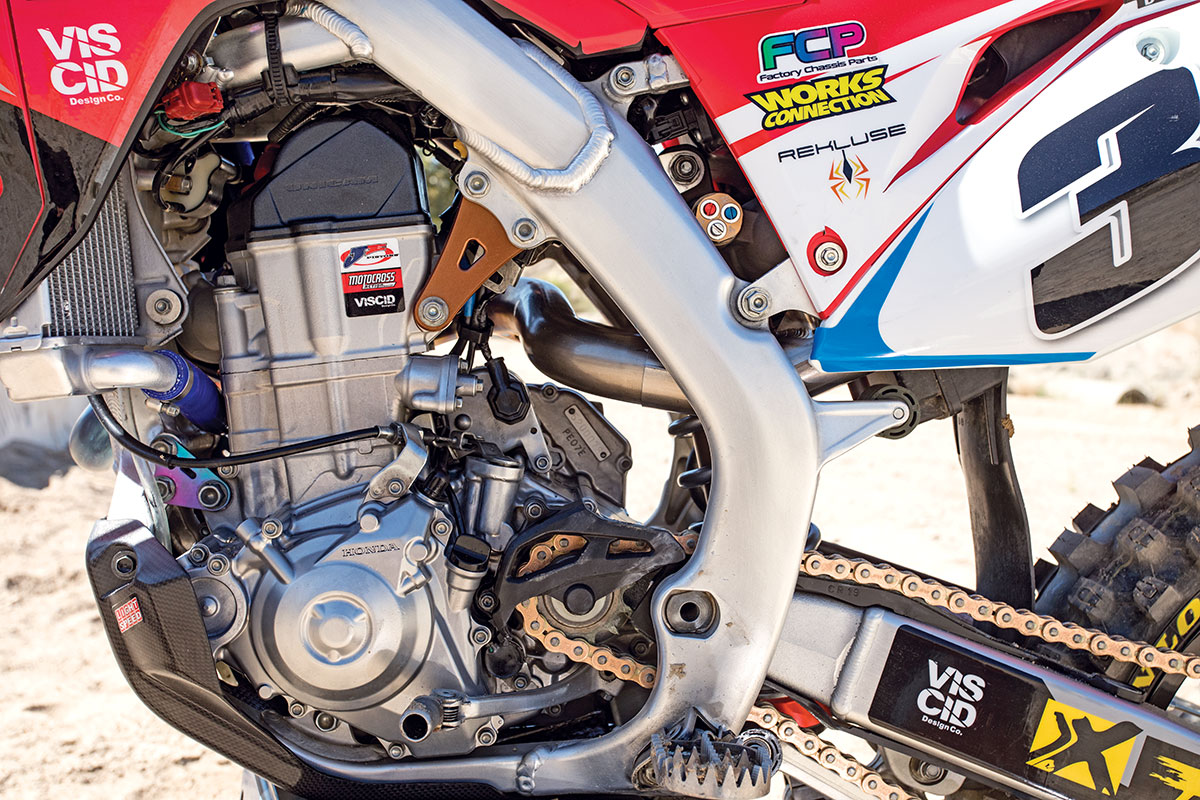

Second, our focus shifted over to two parts that we had already tested and knew worked—the FMF 4.1 RCT CRF450 dual-exhaust system and Rekluse TorqDrive clutch pack. We tested the FMF exhaust on our CRF450 while it was still in stock trim, and all of our test riders approved. The FMF boosted the mid-range power, which in turn helped fill in the power gap, allowing us to ride in a higher gear through the turns. It also helped eliminate the raspy sound of the stock exhausts and gave us that FMF race-bike sound we all love.

Third, the Rekluse TorqDrive clutch pack was a clear choice for us. Honda CRF450s have had weak clutches since 2009’s terrible four-spring experiment, which was a massive failure. The 2019’s 60-horsepower engine was no friend to Honda’s judder spring-equipped clutch. The TorqDrive kit replaced the judder spring and eight stock metal and fiber plates with 12 Rekluse friction plates, 10 steel drive plates and new springs. The extra steel plates and fibers absorb excessive heat and create an improved disengagement release that feels less jerky. The Rekluse TorqDrive is a great addition to any bike, but the improvement is significant on the 2017–2020 CRF450s.

Before we went to the map master, we wanted to button up the Honda’s suspension. We’ve had great experiences with Kayaba’s Factory Kit spring forks and shock from Technical Touch USA. When we built our Dean Wilson privateer YZ450F and our Chad Reed Replica Husqvarna FC450, we came up with valving that was perfect for a wide range of MXA test riders. The Kayaba Factory Kit forks are in the same league as Showa A-kit or WP XACT Cone valve spring forks. We paired the suspension with Xtrig ROCS triple clamps to improve the stability of the forks while adding Xtrig PHDS (progressive handlebar dampening system) bar mounts to absorb uncontrolled impacts to our hands. To continue with the comfort theme, we used Torc1 Racing’s Attack oversized flex crossbar handlebars and Torc1 Kevtek grips. We then swapped out the stock motor mounts and head stays with FCP titanium mounts. As finishing touches, we added a LightSpeed carbon fiber skid plate, Raptor footpegs and a Moto Seat pleated seat cover. Since we had overheating issues with the late-model CRF450s, we swapped out the stock hoses and 1.1 radiator cap with CV4’s radiator hoses and a 2.0 radiator cap. To suit the tastes of the majority of test riders, we had Metal Tek extend the shift lever a few millimeters.

When it came to the parts that make the bike actually move, we had FasterUSA build us custom wheels with its hubs and used Excel’s Takasago rims and Dunlop MX33 tires. ProX supplied the hour meter, countershaft sprocket, rear sprocket and roller chain. A TM Designworks chain guide, Maxima oil and Viscid graphics pulled it all together.

Let’s recap: After we added the J.E. piston, FMF exhaust, Rekluse clutch, KYB suspension and aftermarket upgrades, we took our CRF450 to Jamie Ellis at Twisted Development and told him what we were looking for. Jamie went to work on the dyno and computer to design custom mellow and aggressive maps for us to test. Jamie Ellis is an electronic genius, and he was able to fill in the CRF450 gap and smooth out the power—at least in his workshop. It was up to the test riders to determine if the things we did actually made a difference in MXA’s real world—the racetrack.

TWISTED DEVELOPMENT DESIGNED US A MELLOW MAP AND AN AGGRESSIVE MAP. SURPRISE, MISTAKES WERE FEWER AND FATIGUE WAS LESS WITH THE MELLOW MAP.

Guess what? Within the first lap, it was clear that something was wrong. Actually, we knew exactly what was wrong. The rear shock was set up for a sumo wrestler. Someone had put the wrong spring on the shock. It was an understandable error, because Kayaba Factory Kit shocks are completely different from stock shocks. They don’t use the same spring rate, not by a long shot. The Kayaba Factory Kit shock doesn’t need the same stiff spring as the stock shock. We tried switching from our light test riders to the big boys, but even they hated the feel of the stiff rear shock. In the end, Wrench 42 Motorsports in Temecula swapped out the 5.5 kg/mm spring for the correct 4.9 kg/mm spring, and we were back to the races without the rear end trying to catapult us into orbit.

With the shock issues resolved, we refocused our attention on the maps that Twisted Development designed for us—a mellow map and an aggressive map—and the stock map (for comparison). With the mellow map, test riders were able to roll on the throttle without worrying about a big hit on the exit of corners. Mistakes were fewer, and fatigue was less with the mellow map, because we were able to ride the bike instead of the bike riding us. With smooth power, our testers found that the rear wheel found more traction, and they were able to push harder because they weren’t afraid. Unlike in drag racing, the slower map actually improved lap times. Quick tests of the aggressive and stock maps proved that every test rider preferred the easier-to-ride and more-usable mellow map in race situations. Even our National Pro test riders, who normally go all aggro, were fans of the Jamie Ellis-derived mellow map.

The high notes just kept coming. The Rekluse TorqDrive clutch was incredible. It had an easy pull, predictable release point and incredible hook-up torque. The Kayaba Factory Kit suspension made the CRF450 more stable coming down fast straightaways. The fast-twitch characteristics of the Honda chassis made the test riders lean towards a stiffer suspension setup than on the competition’s bikes.

Aiding overall feel were the FCP titanium motor mounts and CNC-machined aluminum head stays. When hitting acceleration and braking bumps, the titanium engine mounts are designed to allow the frame to flex, which is a big deal on a frame as stiff as the CRF450’s. The wrecking crew also had nothing but praise for the Xtrig preload adjuster on the Kayaba shock. With a battery-powered drill and an 8mm socket, we could set race sag in seconds.

All was not rosy on our CRF450 project bike. The front and rear brakes had fade problems—eventually, we removed the plastic rotor guards, front and rear (and for the 2020 Honda we removed the rear rotor guard from under the swingarm). These plastic covers block airflow, and airflow is what keeps the rotors from overheating the pads. If the pads overheat, it transfers heat to the caliper and eventually bubbles the brake fluid. As the brake power in the front faded, the lever became spongy. Meanwhile, out back, test riders had to lay off the rear brake to keep the fluid from boiling.

Even with the 2.0 CV4 radiator cap, we still lost some coolant once the bike got hot, but it wasn’t as bad as usual. The MotoSeat and Raptor footpegs helped keep us planted on the chassis, but the MotoSeat’s pleated seat cover was too aggressive. We switched it out for the stock seat cover, but then we slid backwards under acceleration. This was a great example of the importance of a grippy seat cover—but it can’t be too grippy.

And there you have it—a brief history of Honda’s last 10 years of development, MXA’s strategic plan, the products we used to get us to our target, the occasional unforeseen pitfalls of building a project bike, and eventually, and expensively, a better Honda CRF450.

CRF450 SUPPLIER LIST

Twisted Development: www.td-racing.com

Technical Touch: www.technical-touch.com

Xtrig: www.technical-touch.com

Torc1 Racing: www.torc1racing.com

Light Speed Carbon: www.lightspeedcarbon.com

Raptor Titanium: www.raptortitanium.com

ProX: www.pro-x.com

Twin Air: www.twinair.com

Factory Chassis Parts: www.fcpracing.com

FMF Racing: www.fmfracing.com

TM Designworks: www.tmdesignworks.com

Dunlop: www.dunlopmotorcycletires.com

Maxima Oil: www.maximausa.com

Moto Seat: www.motoseat.com

Viscid Graphics: www.visciddesign.com

Rekluse: www.rekluse.com

JE Pistons: www.jepistons.com

CV4: www.cvproducts.com

Faster USA: www.fasterusa.com

Excel: www.rkexcelamerica.com

Comments are closed.