TEN THINGS YOU NEED TO KNOW ABOUT WHEEL BEARINGS

(1) Simple Simon. The wheel bearings on a motocross bike are simple. If they are installed, aligned and seated properly, they should give you no trouble. If they aren’t, they can cause the rear wheel to cock, throw the chain, break the side case and destroy the hub. Trust us; it isn’t pretty. Bearings can be made of stainless steel, chrome steel or even silicon nitride ceramic material. Hybrid bearings utilize ceramic balls and steel races. Hybrid bearings are readily available if you choose ceramic for this application.

(2) Large rider. Believe it or not, there is a very low demand placed on the wheel bearings of a motocross bike. A typical wheel bearing is rated for 19,000 rpm and a load of 1574 pounds of force. At maximum rpm and maximum load, it should rotate for one million revolutions, which is over a thousand miles. At 60 mph, a 21-inch wheel (including the tire) is only spinning at 960 rpm. The same bearing is rated for a 30,000-pound load. We don’t have room for our math, which describes the free-falling mass of a bike and rider and the approximate time of deceleration with suspension, but suffice it to say that it would require a large rider and a very big jump to reach the load limit of the bearing.

(3) Physics: High school physics leads to one important conclusion: the bearings in a wheel don’t wear out due to the forces imposed by motocross conditions; they wear out from the intrusion of grit and grime. In many ways, the quality of the seals is more important than the quality of the balls.

(4) Sealed bearings. Since grit and grime are the enemies of ball bearings, wheel bearings can have outer seals on the wheels and sealed ball bearings. Additionally, some bearings have seals on one side only (on the outward side). This provides protection while still allowing access for cleaning and regreasing on the other side. Putting seals on both sides of the bearing provides even more protection, but the bearings cannot be serviced. Sealed bearings are not designed to be regreased. Once a sealed bearing has been compromised, it’s best to replace it.

(5) Service. Servicing a bearing is not high on the list of maintenance duties for most riders. They usually just replace the seals when they go bad instead of working on them. In a pinch, the seals can be removed (very carefully with a flat-blade screwdriver) and reused when working. We don’t recommend this, because in most cases the seals are destroyed and have to be replaced anyway.

(5) Service. Servicing a bearing is not high on the list of maintenance duties for most riders. They usually just replace the seals when they go bad instead of working on them. In a pinch, the seals can be removed (very carefully with a flat-blade screwdriver) and reused when working. We don’t recommend this, because in most cases the seals are destroyed and have to be replaced anyway.

(6) Grease. To service a bearing, thoroughly rinse it with solvent while rotating the bearing manually. Beware of harsh solvents near the rubber seals. Wipe grease from inside the hub. Use paper towels to avoid lint contamination. Air dry the bearing (do not spin it to dry it). Put grease into your palm and press the bearing into it, working it through thoroughly.

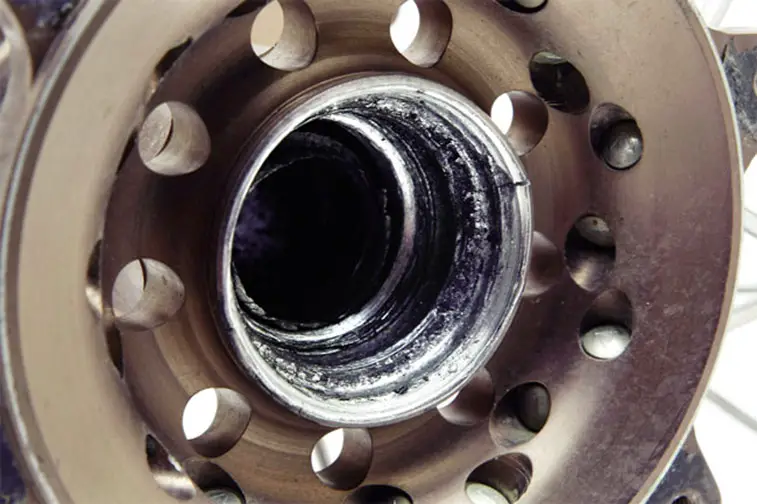

(7) Quick check. It is important to know when a bearing is wearing out. A quick, rudimentary check is to grab the wheel rim while stabilizing the bike and apply side-to-side (axial) force to check for play. There should be less than 1/16th of an inch of side-to-side movement. Check for rubbing, spalling (pieces chipped off) or brinelling (dents inside the race). The telltale signs of these are roughness when spinning.

(8) Axial loads. Even though wheel bearings can take tremendous loads radially, their Achilles heel is axial loads. If a side load tries to push the inner sleeve out of line with the outer races, it will rapidly accelerate wear. This is why having all the correct-fitting spacers and having everything installed properly is crucial. Spacers should contact only the outer portion of the race, and the spacers between the bearings are just as important to remember as the wheel spacers. Pivot Works offers wheel spacers with built-in seals for extra protection.

(9) Hammer time. Here are some wheel bearing tricks. Before installing bearings, take note of the depth they must drop to inside the hub so that you can make sure they are fully seated without excess pounding. Use a brass or aluminum punch to gently tap around the bearing edges to seat the bearing. Whether installing or removing a bearing, be sure to work around the edges evenly. Do not let the bearing get cocked to one side. You can freeze the bearings and/or carefully heat the hub before installation to take advantage of thermal expansion. Honda rear-wheel bearings on the sprocket side are a bit more challenging than the rest. Motion Pro’s $20 bearing retainer tool is specially made to help.

(10) Ceramics. Ceramic bearings generate a lot of buzz and have a lot of advocates, even though the advantages of heat performance, which is usually a prime reason for going ceramic, are nonissues in a motocross application. Ceramic bearings can be up to 60 percent lighter, 50 percent stiffer and 70 percent smoother than steel bearings. This translates into less rolling resistance at any speed. In the end, the price of ceramic bearings is exorbitant, even for most pro teams. The amount of resistance to wheel spin due to disc brakes, the chain and the chain’s contact points over-shadow a lot of the gains that a ceramic bearing offers.

Comments are closed.